CHENcan DF Series 3D Printer Machine for Mold Industry –(Additive Manufacturing) Technology – Its advantages are primarily reflected in its unique manufacturing approach and broad application potential:

1. Near Net Shape: Switching from subtractive to additive manufacturing, using only the required material with minimal waste (traditional machining can waste up to 90%).

2. Shortened Development Cycle: From design to physical part in just hours to days, accelerating product validation (e.g., automotive and aerospace prototypes).

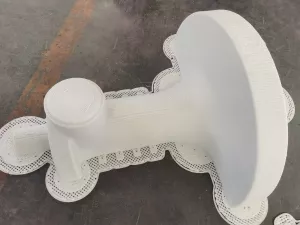

3. Design Freedom: Capable of printing any shape while achieving integrated complex assemblies—multiple components can be printed as a single unit, reducing assembly steps (e.g., rocket engine components).

4. No Molds Required: Directly manufactures from digital models, eliminating dependence on traditional tooling, making it ideal for complex geometries (e.g., hollow structures, internal channels).

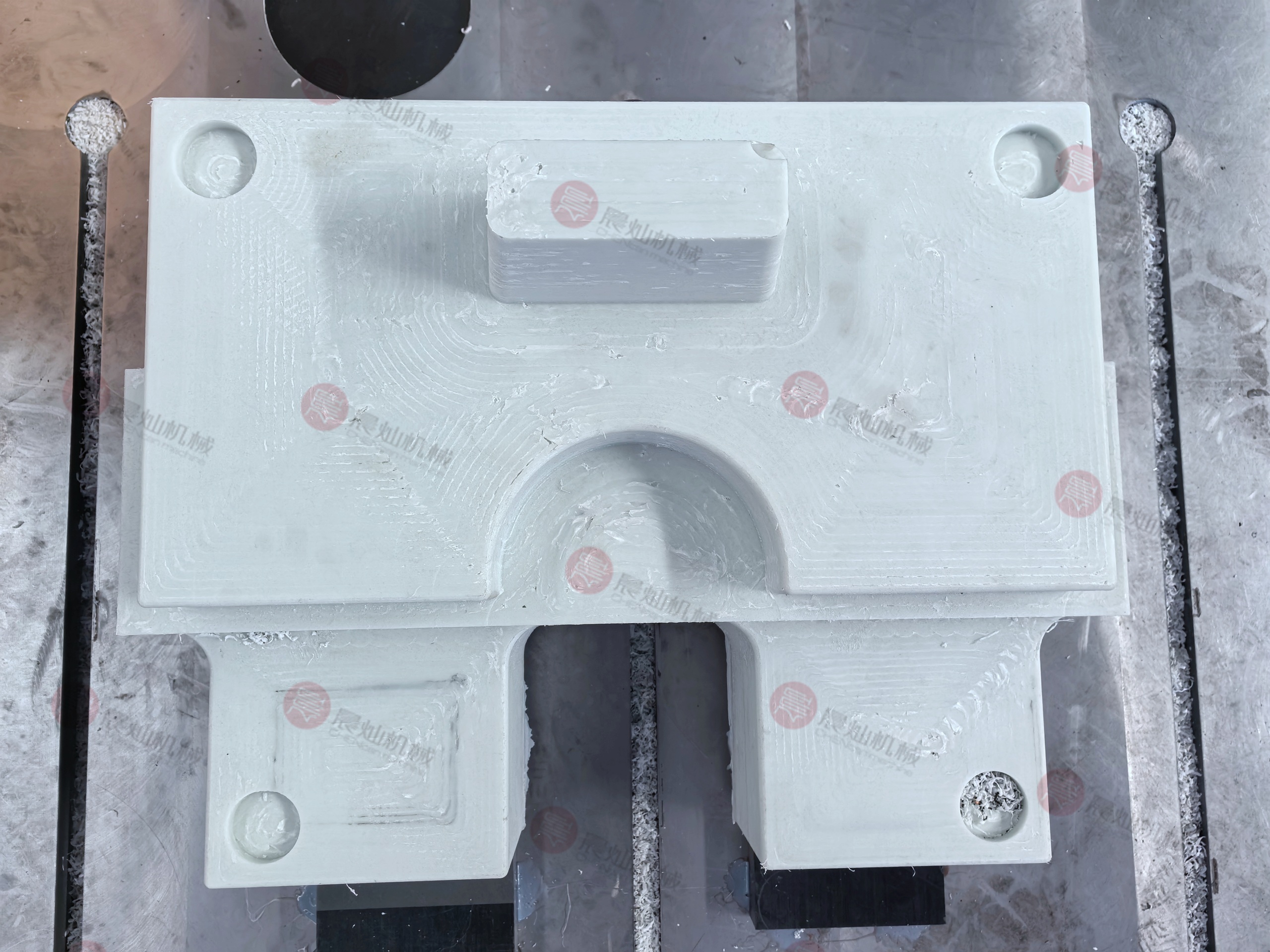

5. Plastic Molds: Easy to store and reusable multiple times, lasting twice as long as traditional wooden molds.

Application of 3D Printer Machine for Mould Making:

| Industry |

Material |

| Thermoformed Industry |

Composites |

| Aerospace Industry |

Plastic |

| Casting Industry |

PP, PC, ABS,PA |

| Gas & Oil Industry |

|

| Automotive Industry |

|

| Marine Industry |

|

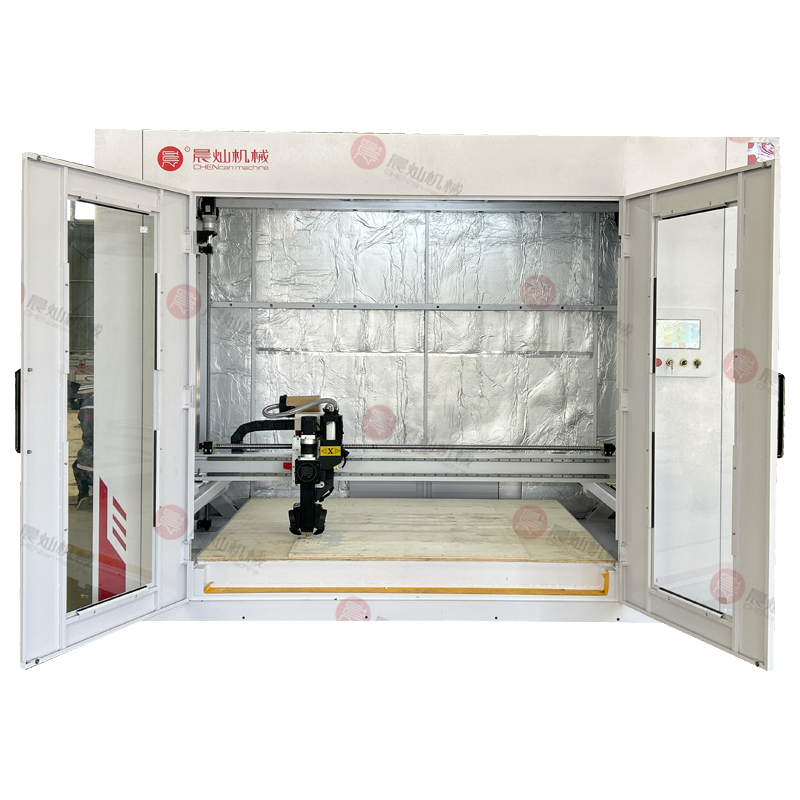

Technical Parameters of 3D Printer Machine for Mould Making:

| Stroke Size(mm) |

X:1600 Y:1600 Z:1200 |

| Control CNC |

CHENcan CNC |

| Data Transmission |

Ethernet, USB, WIFI |

| Software |

Particle printing software, compatible with Cura, Orca, Simplify 3D and other general slicing software |

| Support File Formats |

STL, AMF, 3DMF etc |

| Transmission Mode |

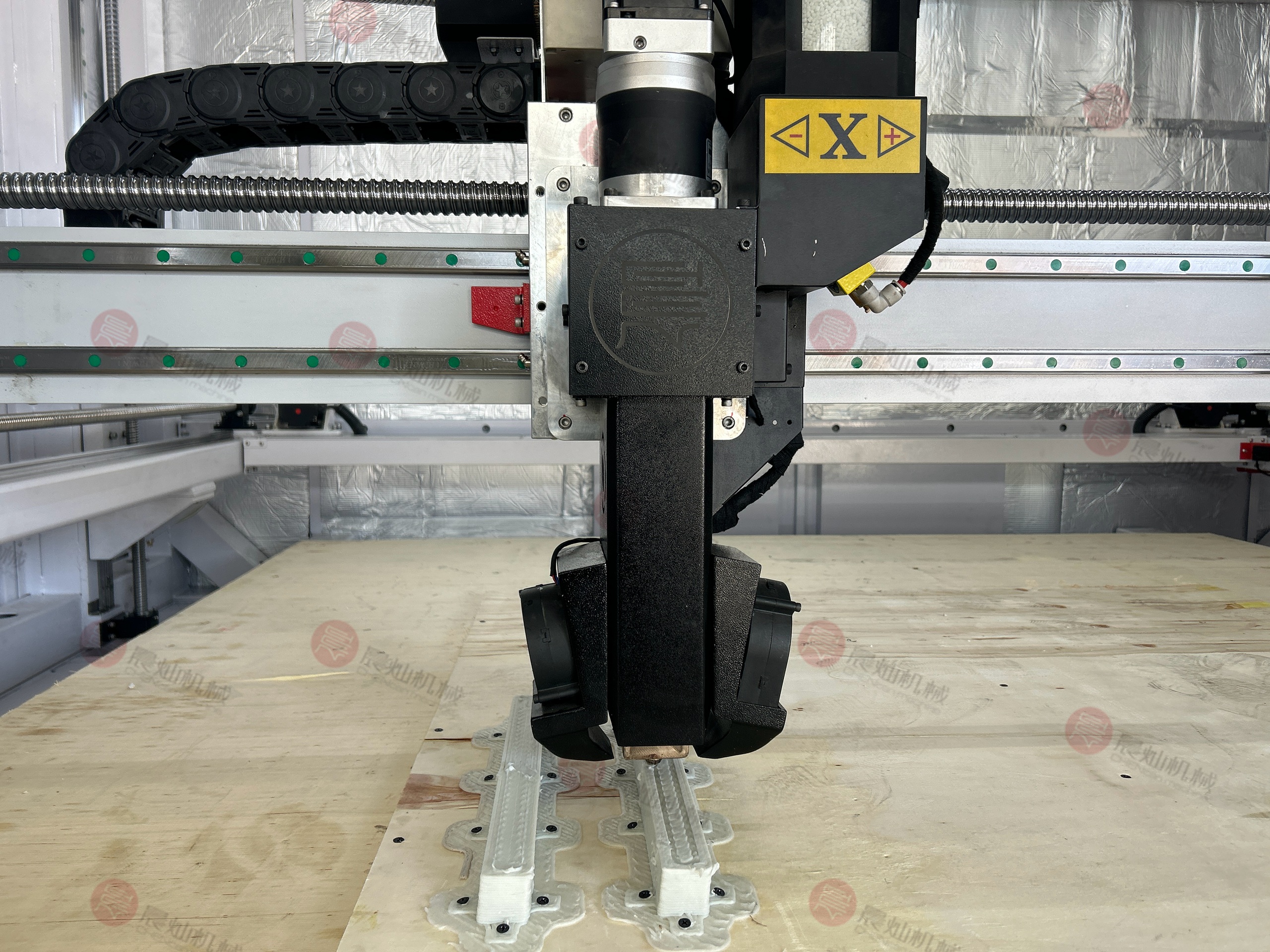

XYZ: High Precisioin Ball screw |

| Drive Motor |

Servo Motor |

| Extrusion System |

HNC |

| 3 Heating Sections |

| Max Heating Temperauture: 350° |

| Particles Raw Material Form |

| Max Extrusion Volume 8Kgs/H |

| Print Nozzle diameter |

2mm-6mm |

| Drive Type |

AC Servo Drive |

| Work Model |

0.025/0.025/0.025 |

| Max Working Speed X/Y/Z(mm/s) |

200/200/10 |

| Repeatability X/Y/Z(mm/m) |

+/-0.15mm |

| Mechanical Structure |

Steel Welding Structure with fully enclosed metal cover |

| Printing Table |

Steel Table with Wood Panel |

| Auto Feeding System |

Yes |

| Air Pressure (kgf/cm2) |

≥0.06 |

| Input Voltage |

220/380V 3P |

| Drying System |

Optinal |

| Optinal Stroke Size(mm) |

1600*2000mm / 2000*3000mm |

3D Printer Machine for Mould Making project: