Features and Advantages of high efficiency pellet 3D printing equipment for mold making:

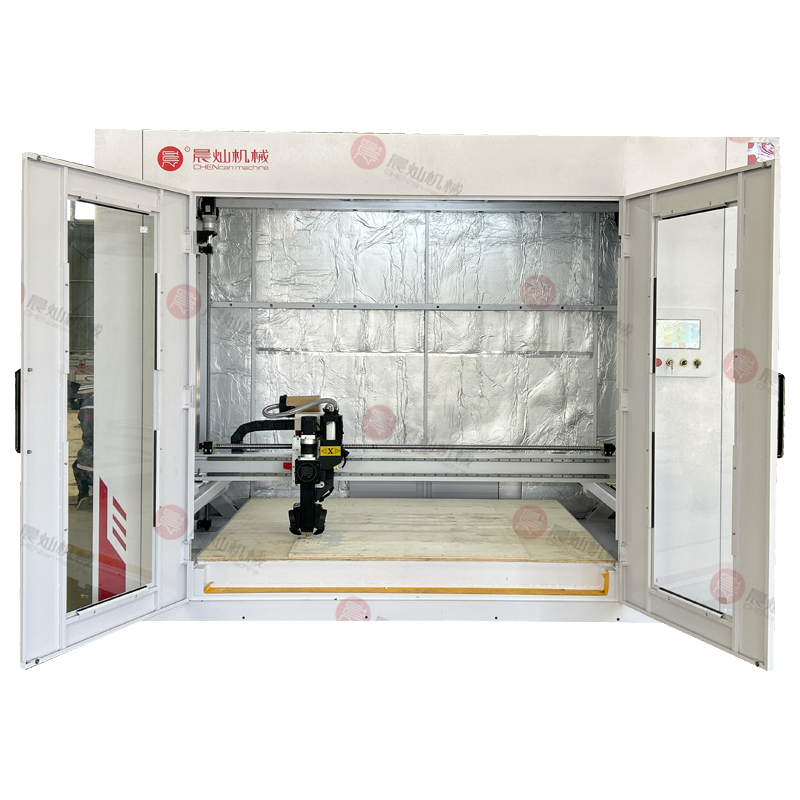

CHENcan DF Series High Efficiency Particle 3D Printing Mold Equipment –(Additive Manufacturing) Technology – Its advantages are primarily reflected in its unique manufacturing approach and broad application potential:

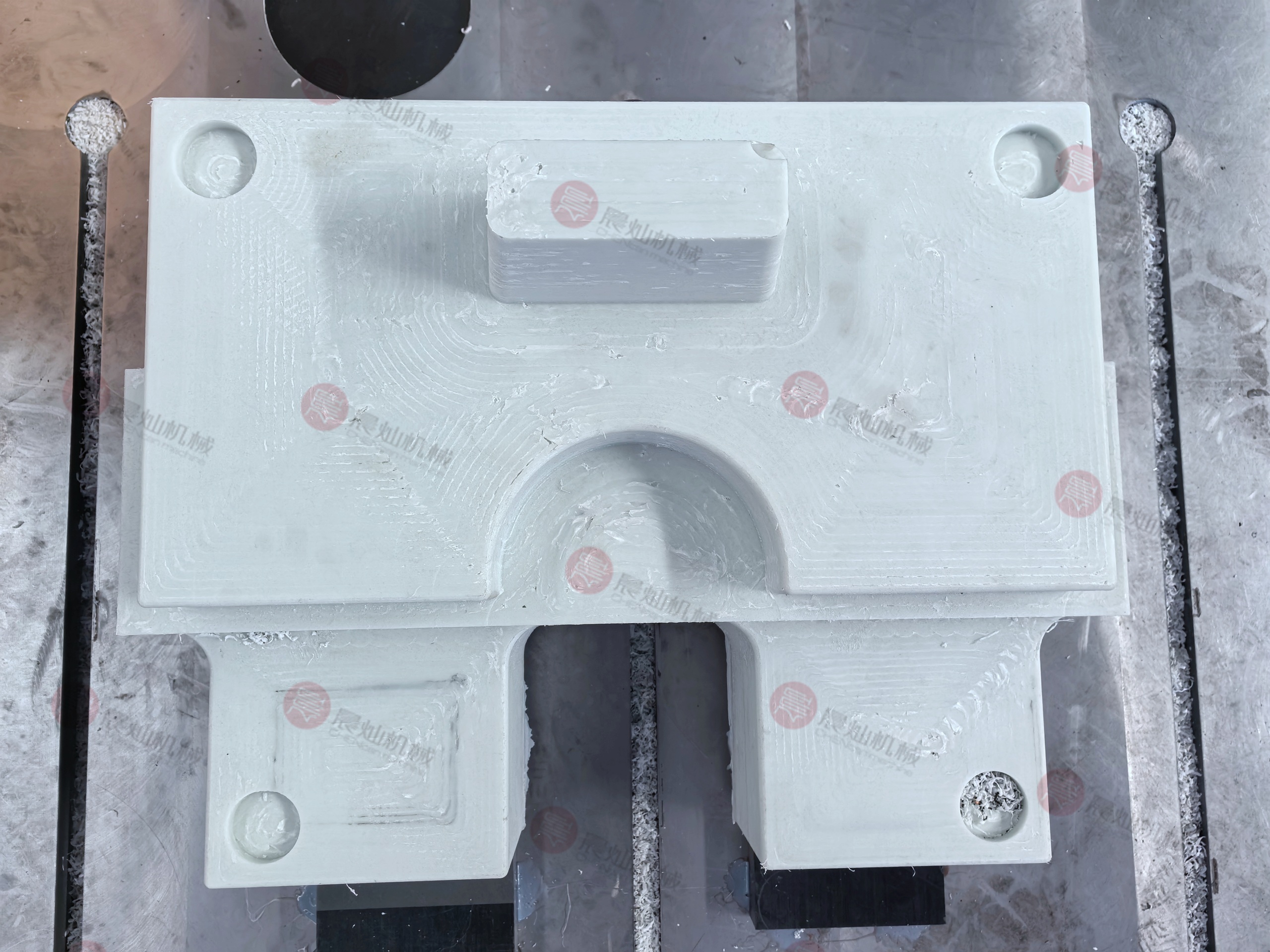

1. Near Net Shape: Switching from subtractive to additive manufacturing, using only the required material with minimal waste (traditional machining can waste up to 90%).

2. Recyclable Materials: Further significantly reduces production costs.

3. Low-Cost Trial & Error: Designers can quickly modify models and reprint, lowering R&D costs.

4. Shortened Development Cycle: From design to physical part in just hours to days, accelerating product validation (e.g., automotive and aerospace prototypes).

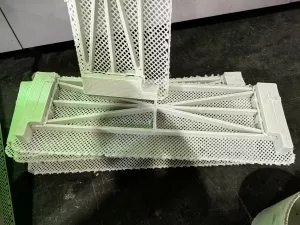

5. Design Freedom: Capable of printing any shape while achieving integrated complex assemblies—multiple components can be printed as a single unit, reducing assembly steps (e.g., rocket engine components).

6. No Molds Required: Directly manufactures from digital models, eliminating dependence on traditional tooling, making it ideal for complex geometries (e.g., hollow structures, internal channels).

7. Plastic Molds: Easy to store and reusable multiple times, lasting twice as long as traditional wooden molds.

8. Easy operatoin, the control system supports direct reading of 3D drawings, no need to learn complex formatting or parameter settings. It can easily print kinds tooling, molds, sculptures and other products to meet your production needs.

Application of high efficiency pellet 3D printing equipment for mold making

| Industry |

Material |

| Thermoformed Industry |

Composites Materials |

| Aerospace Industry |

Plastic |

| Automotive Industry |

PP, PC,PA |

| Marine Industry |

ABS, Nylon |

| Casting Industry |

|

| Oil & Gas Industry |

|

| |

|

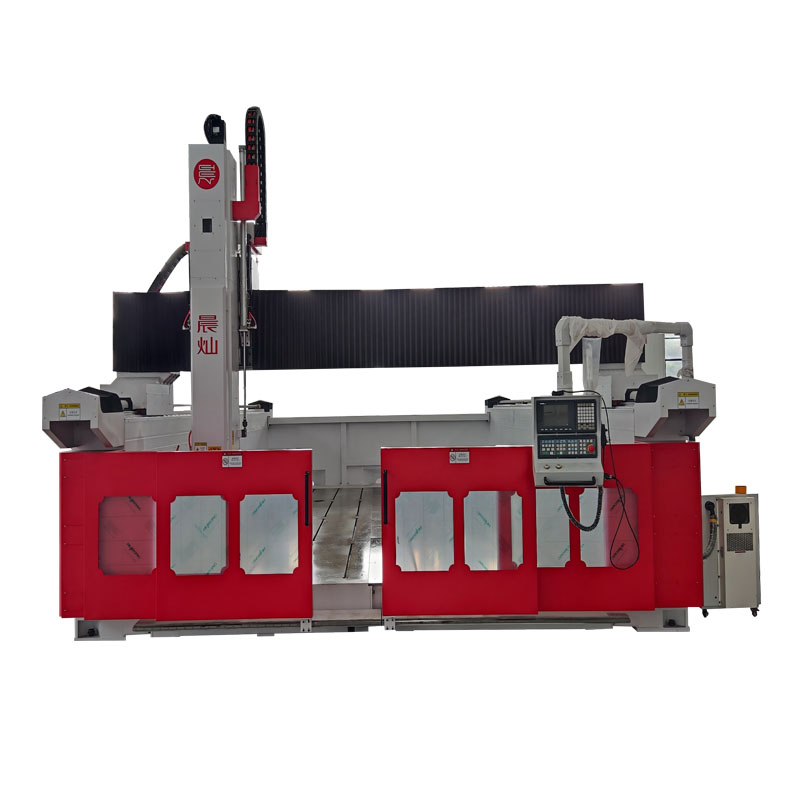

Technical Parameters of high efficiency pellet 3D printing equipment for mold making:

| Model |

DF2030 |

| Stroke Size(mm) |

X:2000 Y:3000 Z:1200 |

| Control CNC |

CHENcan CNC |

| Data Transmission |

Ethernet, USB, WIFI |

| Software |

Particle printing software, compatible with Cura, Orca, Simplify 3D and other general slicing software |

| Support File Formats |

STL, AMF, 3DMF etc |

| Transmission Mode |

XYZ: High Precisioin Ball screw |

| Drive Motor |

Servo Motor |

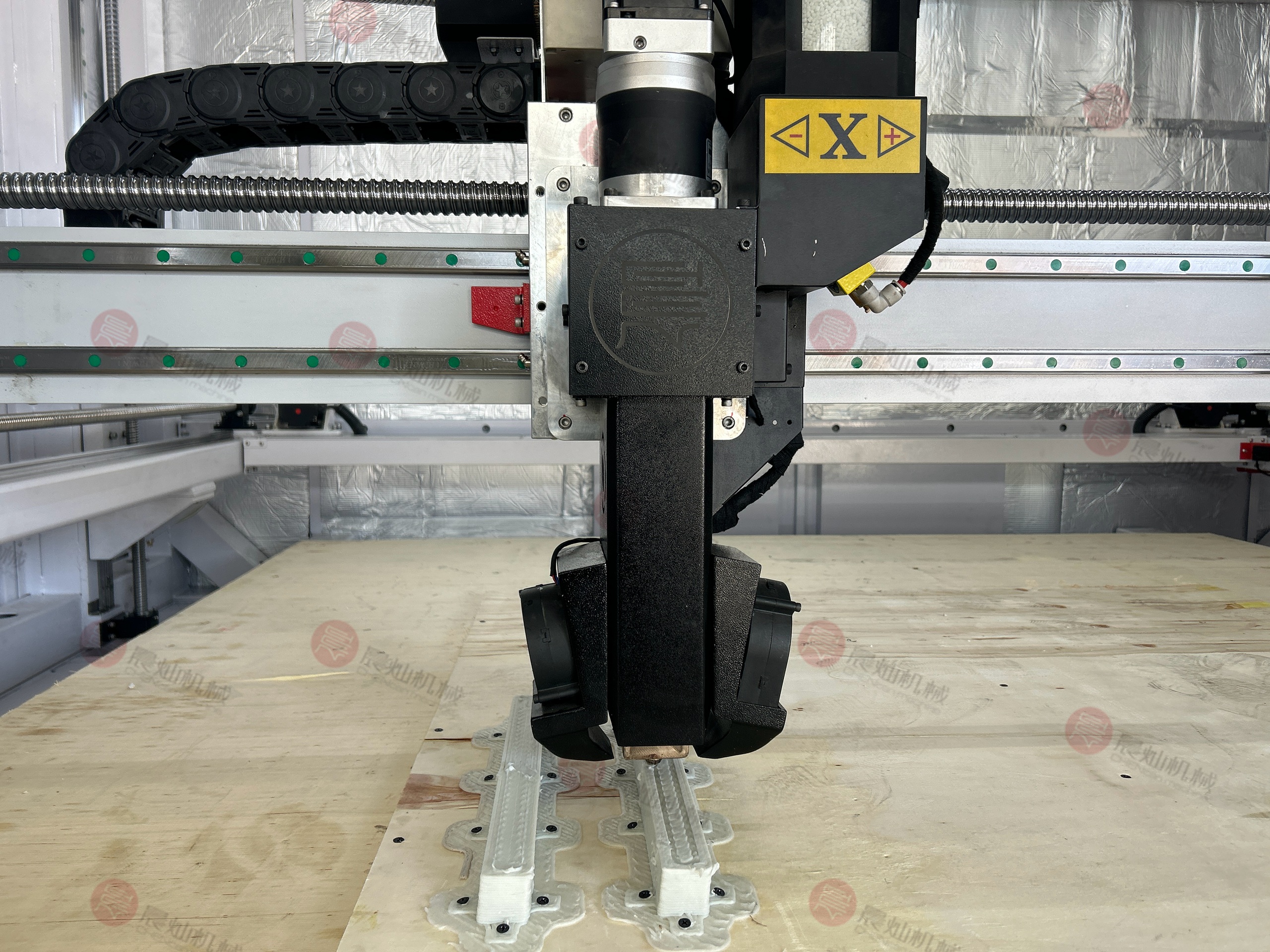

| Extrusion System |

HNC |

| 3 Heating Sections |

| Max Heating Temperauture: 350° |

| Particles Raw Material Form |

| Max Extrusion Volume 8Kgs/H |

| Print Nozzle diameter |

2mm-6mm |

| Drive Type |

AC Servo Drive |

| Work Model |

0.025/0.025/0.025 |

| Max Working Speed X/Y/Z(mm/s) |

200/200/10 |

| Repeatability X/Y/Z(mm/m) |

+/-0.15mm |

| Mechanical Structure |

Steel Welding Structure with fully enclosed metal cover |

| Printing Table |

Steel Table with Wood Panel |

| Auto Feeding System |

Yes |

| Air Pressure (kgf/cm2) |

≥0.06 |

| Input Voltage |

220/380V 3P |

| Drying System |

Optinal |

| Optinal Stroke Size(mm) |

1600*1600mm / 2000*1600mm |

High Efficiency Pellet 3D Printing Equipment for Mold making project: