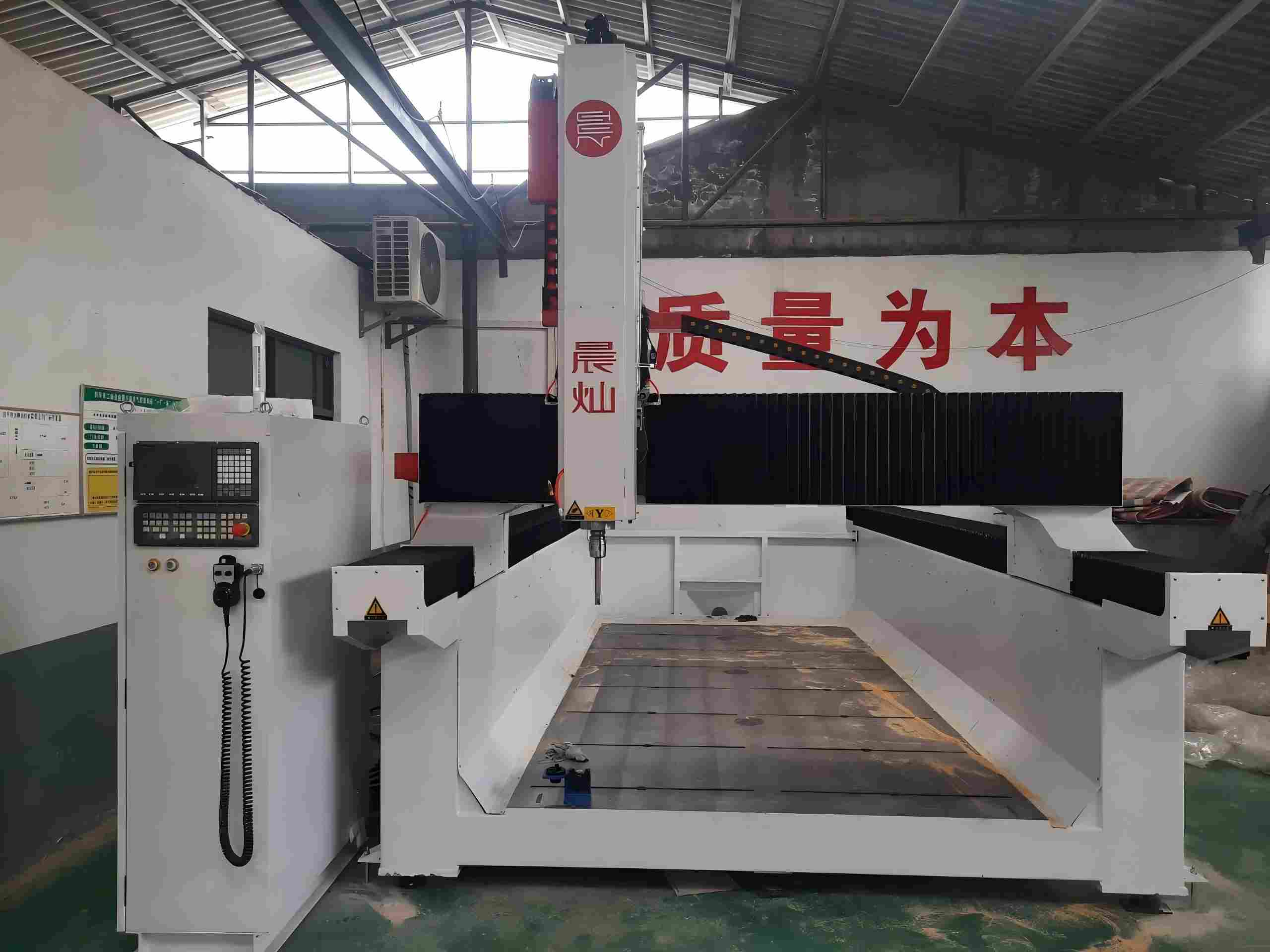

Features and Advantages of 3 axis cnc mold for mold and sculpture making

1. The machine body adopts thick-walled sqaure tube welding technology, all weld has passed strict inspection to eliminate the hidden dangers of false welding and welding leakage. To ensures long-term stable operation of the entire machine, effectively reducing precision lost and extending the machine’s lifetime.

2.All XYZ axes are equipped with a high-precision ball screw, this unique drive design ensures precise positioning while increasing machine move speed, balancing machining accuracy and production efficiency.

3. All XYZ axes are equipped with Taiwan square rails, their excellent guiding performance effectively suppresses vibration during high-speed movement, ensuring smooth moving and guaranteeing high-quality machining surfaces.

4. The entire machine usd powerful AC servo drive with a bus-based communication. This streamlines the wiring layout and enhances interference resistance of the signals, simplifying initial installation and making maintenance easier.

5. Key mechanical components use high-temperature tempering, which not only reduces material hardness but also completely eliminates th internal stress. This process highly improves component stability, ensuring the machine maintains high-precision over the long term.

6. All electrical parts are choose top brands and are designed and manufactured with CE standards, ensuring the safety, reliability, and compliance of the equipment’s electrical system from the beginning.

7. During the installation and commissioning phase, high-end testing equipment such as laser levels, laser alignment equipment, marble squares, test bar, and laser interferometers are used, and standardized procedures are strictly followed. This ensures that each machine with best performs before shipment.

8. Before delivery, each machine will do a 24-48 hour continuous moveing test to fully verify operational stability and processing performance. Customers can begin production directly after receive the machine without any additional commissioning, to saving time.

9. The whole machine with a one-year warranty, and the Chencan team provides lifetime technical support. From installation to maintenance, we provide professional support throughout the entire process, eliminating any worries about production.

3 axis CNC mold machine for EPS foam mould making Industry & Materials:

| Industry |

Material |

| Automotive |

Wood, MDF, PVC, Foam, MDF, Plastic |

| Aerospace |

Composites materials |

| Marine |

Epoxy, Putty |

| Railway |

FRC, GRC |

| Casting Patterns and Moulds |

Fiber Galss, Sand… |

| Sanitary Ware |

|

| Sculpture Engineering |

|

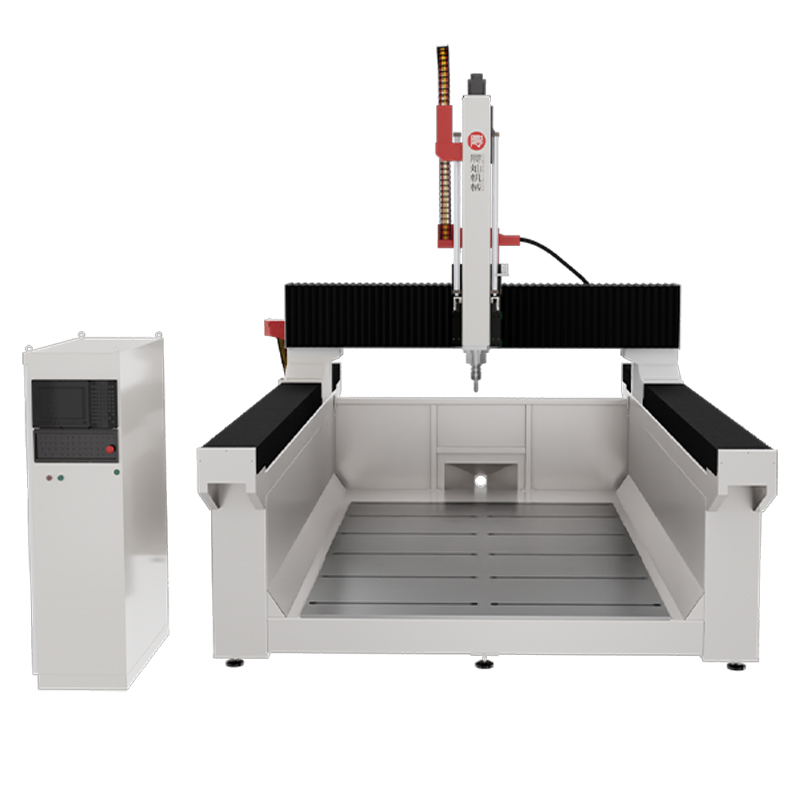

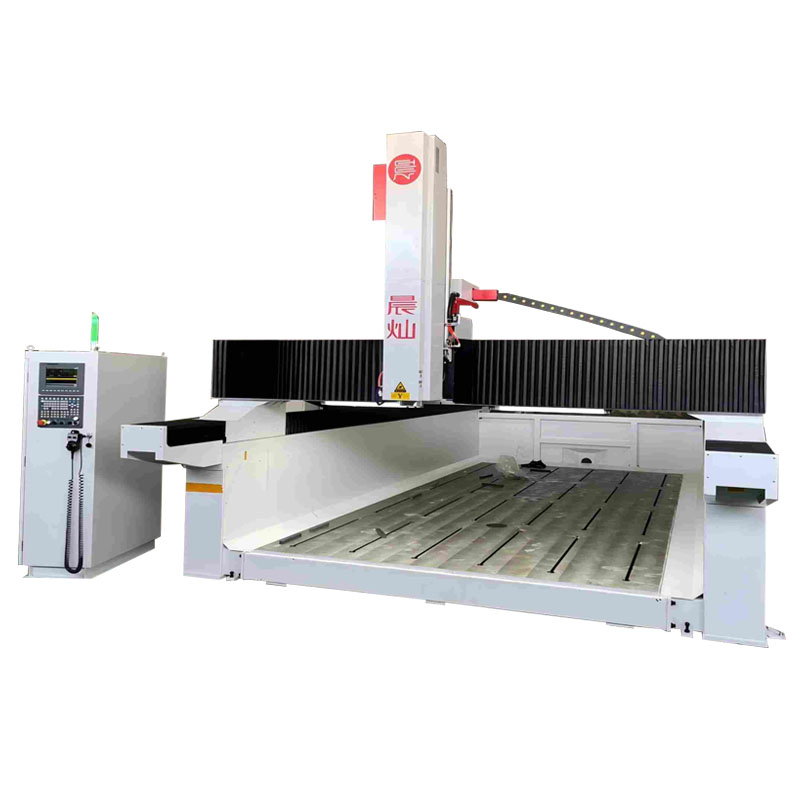

Technical Parameters of mold and sculpture making:

| Model |

BS2040 |

| Table Size1 |

4000*2000mm |

| Working Area (mm) |

X:4000 Y:2000 Z:1000 |

| Spindle Type |

Electronic Spindle |

| Spindle Power |

7.5Kw ATC Spindle |

| Spindle Speed |

20000rpm/min |

| Spindle Cone |

BT40 |

| Max Tool Diameter |

Φ32mm |

| Max Tool Weight |

5KGS |

| Control CNC |

HNC System |

| Drive System |

HNC servo motor and drivers |

| Drive Type |

XYZ: High precision ball screws |

| Work Model |

AC Servo Drive |

| Max Working Speed X/Y/Z(mm) |

20/20/8 |

| Max Rapid Speed X/Y/Z(m/min) |

40/40/15 |

| Positioning Accuracy X/Y/Z(mm/m) |

0.08/0.06/0.05 |

| Repeatability X/Y/Z(mm/m) |

0.06/0.04/0.03 |

| Work Table type |

Iron Table with T slot |

| Air Pressure (kgf/cm2) |

≥0.06 |

| Total Power (KVA) |

20 |

| Gross Weight (T) |

6 |

| Layout Szie (mm) |

5500*4000*3600mm |