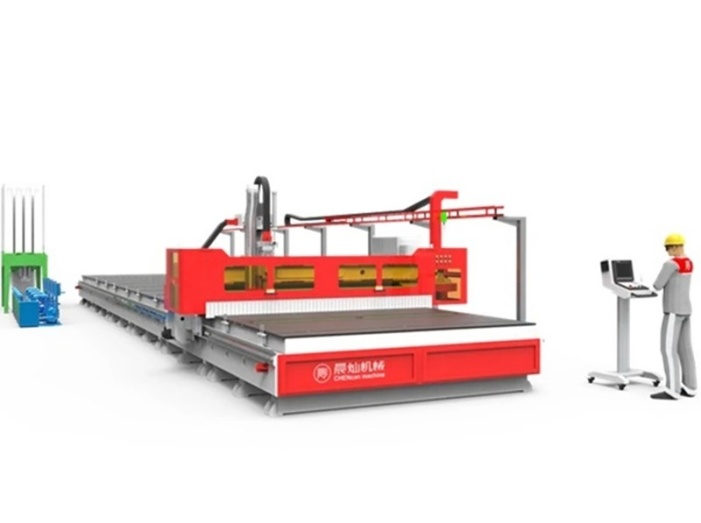

In panel CNC cutting, figuring out which materials can be machined and which can’t is not always easy. Material makeup, strength, tool fit, and machine setup all matter. For makers aiming for top-notch panels—like for cars, RVs, or composite housing—picking the right equipment is crucial. CHENcan offers a wide range of high-performance CNC systems for various panel tasks. With five-axis machining centers, composite panel sawing and milling setups, and routers with circular saws, CHENcan delivers precision and flexibility. Their machines handle multi-axis designs and hybrid tech for tough materials.

What Defines the Boundary Between Machinable and Unmachinable Materials?

The line between machinable and unmachinable depends on material traits, machine power, and tool match. Most materials can be cut with CNC, but not all cut well or easily.

Material Properties That Influence Machinability

A material’s qualities—like hardness, brittleness, stretch, or density—shape how it cuts. Soft stuff like foam or wood composites is easy. Brittle or heat-conductive metals can crack or overheat tools. Cutting composites like carbon fiber, glass fiber, PMI, PET, EPS foam, or plastics needs clean cuts to avoid damage. A shop had chipping issues with glass fiber until slowing the feed rate.

Tooling Compatibility and Machine Capabilities

Machinable materials need the right tools. High-speed spindles with proper RPMs suit hard plastics. Abrasive laminates need tough tools to last. Spindle brand and power can match material needs. A shop cutting aluminum sheets doubled tool life with a stronger spindle.

Thermal and Mechanical Stress Considerations

Cutting makes heat and stress that can warp panels. Thermoplastics may melt; composites might split with fast feeds. A sealed cabin design keeps high-speed work clean, managing heat. One operator saw less warping in PET panels with better cooling.

Can All Composite Panels Be CNC Cut with Precision?

Composite panels, with layered cores, are tricky. Many work with CNC if tools are right, but some need special care.

Structural Complexity of Composite Materials

Composites mix hard outer layers with soft cores, like aluminum-polyurethane-aluminum. Each layer cuts differently. Smooth edges need tight feed and spindle control. Systems for linear or curve cuts, like car interior parts, adapt to complex structures. A furniture maker shredded a panel core by cutting too fast—slowing helped.

Risk of Delamination or Surface Damage

Delamination happens when layers split from vibration or wrong bits, especially in fiberglass or honeycomb cores. The Sandwitch Panel Cutting CNC Machine uses slotting to ease stress. A boat builder cut delamination with this machine.

Importance of Specialized CNC Equipment

Basic routers may lack stability for composites. Multi-process setups—like oscillating knives or saws—work better. Technologies like spindle or water jet tailor cuts to layers. A shop cutting RV panels saved 20% setup time with an oscillating knife.

How Do Material Thickness and Density Affect CNC Cutting Feasibility?

Thickness and density impact tool wear and cut accuracy. Thick, dense materials need slower feeds and strong spindles.

Impact on Cutting Speed and Tool Wear

Thicker panels resist tools, wearing them out faster unless using shallow passes. Dense hardwoods make more heat. A 15KW or 24KW spindle with 0-24000rpm and HSK63F/HSK63A cuts dense materials well. A shop cutting oak extended tool life by slowing feeds.

Necessity for Multi-Axis Support Systems

Single-axis control struggles with thick panels needing angled cuts. Multi-axis systems keep tools at ideal angles. The L-shaped AC double-swing head tilts for complex contours. A campervan builder saved hours cutting angled insulation.

Limitations in Depth Control and Precision

Accuracy fades in deep cuts if tools lack rigidity. Vibration grows without strong gantries or RTCP. A system with RTCP boosts precision in deep cuts. A housing panel maker got tighter tolerances with RTCP.

Are There Specific Materials That Resist CNC Machining?

Some materials resist clean cuts due to brittleness or abrasiveness, needing special setups or methods like water jet.

Brittle or Fragile Substrates Like Glass-Reinforced Panels

Glass-reinforced composites crack unless cut slowly with sharp tools. Cutting carbon fiber needs vibration-dampening machines. A shop replaced tools weekly until getting a dampened CNC.

Highly Reflective or Heat-Conductive Metals

Aluminum alloys conduct heat fast, tough for lasers without cooling. Spindle-driven cuts work better for aluminum alloy. A metalworker halved cut times with a spindle-based CNC.

Abrasive or Resin-Based Laminates

Resins with quartz wear tools fast. Diamond-coated bits and low RPMs keep edges clean. A countertop maker boosted tool life 30% with diamond bits.

What Role Does Machine Configuration Play in Machinability?

Machine design shapes what can be cut—from frame strength to add-ons like saws or vacuum tables.

Advantages of 5-Axis CNC Systems for Complex Cuts

Five-axis machines cut from many angles without moving panels, ideal for RV or boat interiors. The Campervans Caravans 5th Wheel Making CNC Router Spindle And 5axis Circular Saw handles complex angles. A caravan maker cut production time by 15%.

Importance of Spindle Power and Speed Variability

High RPMs suit plastics; low speeds avoid resin melting. A 15KW or 24KW spindle with 0-24000rpm adapts to many materials. A shop cutting mixed panels switched spindles easily.

Integration of Circular Saw Units for Hybrid Applications

Sawing beats routing for straight cuts in sandwich cores. The Campervans Caravans 5th Wheel Making CNC Router Spindle And 5axis Circular Saw avoids machine swaps. A furniture shop saved half a day per batch.

How Does CHENcan Address Challenges in Panel CNC Cutting?

CHENcan builds customizable platforms for specific materials.

Application of CHENcan Sandwich Panel Cutting CNC Machine

This system drills cabin doors and cuts insulation without repositioning. It handles drilling and slotting for composite sheets. A campervan shop sped up assembly.

Use of Campervans Caravans 5th Wheel Making CNC Router

Built for complex wall assemblies, this hybrid handles saw cuts and milling. A trailer maker cut waste by 10%.

Customization Options Based on Material Requirements

For PET foam or laminated wood, machines offer table sizes (1300×2500mm minimum) and vacuum beds. A shop doubled foam panel output with a tailored CHENcan.

FAQ

Q1: Can all composite panels be machined using standard routers?

A: No; some require hybrid systems integrating circular saws due to their layered structure complexity which risks delamination during routing alone.

Q2: What causes delamination during panel machining?

A: High vibration levels from improper feed rates/tool geometry often cause separation between composite layers under stress conditions.

Q3: Are five-axis machines necessary for all applications?

A: Not always—but they’re essential when dealing with angled edges or internal cavities that require non-linear access paths across thick substrates.

Q4: How does RTCP improve machining accuracy?

A: RTCP adjusts tool orientation dynamically relative to part geometry—maintaining consistent contact angle even along curved surfaces during five-axis operations.