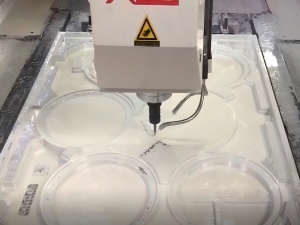

Core Advantages of New Soft Metal CNC Mold Milling Machine for Pattern Making :

In the field of lightweight processing of automobile chassis, heavy duty gantry milling machine for mold mkaing can efficiently process complex structural parts such as aluminum alloy chassis frames and suspension systems, taking into account the speed and precision of lightweight material processing; in the field of railway transit, it can be competent for heavy cutting processing of metal molds such as train body frames and key connecting parts, meeting the stable forming needs of large workpieces, and providing core support for efficient production in the two major fields.

Features of New Soft Metal CNC Mold Milling Machine for Pattern Making :

1. The machine body utilizes a seamless welding process and a high-density cast worktable, annealed at 800°C to eliminate internal stress and ensure a deformation rate of ≤0.001% after long-term use. The base and column utilize a mountain-shaped rib-reinforced design to minimize force flow. Combined with an extra-wide base and widened column bottom span, the machine’s center of gravity is lowered to an optimal stable height, resulting in a 40% increase in torsional strength compared to traditional structures.

2. Imported heavy-duty ball guides are standard on the X/Y/Z axes. The track surfaces undergo high-frequency quenching, resulting in a friction coefficient as low as 0.008 while ensuring rigid support. The lead screw utilizes a C3-grade ground nut drive mechanism with a pre-tension of 15% of the screw’s rated dynamic load, completely eliminating backlash. High-quality couplings ensure motor-screw coaxiality error of ≤0.002mm, resulting in a transmission efficiency exceeding 98%.

3. Stable Spindle Assemble Design: The contact length between the spindle and the plate is optimized to a 1:3 golden ratio, providing balanced support for the entire stroke. Adopt oil cooling system, with constant-temperature coolant circulation controlling internal spindle temperature fluctuations to within ±1°C, effectively minimizing accuracy deviations caused by thermal expansion.

4. Auto Lubrication and Maintenance Warning: Auto lubrication system, coupled with an on-board lubrication pump, ensures uniform lubrication of key components such as the guide rails and lead screw. Oil level and pressure monitoring provides automatic oil shortage alarms.

5. Flexible Chip Removal and Cleaning Design: The machine comes standard with a double-helical chip conveyor and a lifting chip conveyor (extended for heavy-duty operation), achieving a chip removal speed of 3m/min and handling chips up to 50mm in diameter.

6. The spindle nose is equipped with an air curtain dust control and a central air blower, with air pressure reaching 0.6MPa, effectively preventing chips and coolant from entering the spindle, extending bearing life by over 30%.

7. Deeply Compatible CNC System: Equipped with the high-end HNC 818 CNC system, it supports AI toolpath optimization and 3D simulation, enabling proactive detection of vibration risks during heavy cutting and automatically adjusting feed rates. The system also includes a built-in MES interface, enabling intelligent management such as uploading machining parameters and tracking order progress, making it ideal for modern production workshops.

Heavy duty gantry milling machine for mold making Industry & Materials:

| Industry |

Material |

| Automotive Industry |

Aluminum Alloys, Aluminum Profiles |

| Railway Industry |

Copper and others soft metal |

| Aerospace |

Wood, MDF, PVC, Foam, MDF, Plastic |

| Casting Patterns and Moulds |

Composites materials |

Technical Parameters of New Soft Metal CNC Mold Milling Machine for Pattern Making:

| Model |

SM3020 |

| Table Size |

3000*2000mm |

| Working Area |

X:3000 Y:2000 Z:800mm |

| Distance between spindle nose and work table |

100-700mm |

| Work Table type |

Iron Table with T slot |

| T slot |

22-210-10 |

| Max.Woke Table Load |

1.6T |

| Spindle Type |

Powerful Mechanical ATC Spindle |

| Spindle Motor Power |

10Kw big power servo spindle motor |

| Max. Spindle Motor Torque |

47.8 N.m |

| Spindle Speed |

12000rpm/min |

| Spindle Cone |

BT40 or BT50 as optional |

| Spindle Cooling Type |

Oil Cooling |

| Tool Magazine Type |

Carosel tool magazine |

| Tool Magazine Capacity |

12 pcs |

| Max Tool Diameter |

Φ65mm |

| Max Tool Length |

250mm |

| Max Tool Weight |

8KGS |

| Control CNC |

HNC System |

| Drive System |

HNC servo motor and drivers |

| Drive Type |

XYZ: Grinding ball screws |

| Pront Protective Door |

Yes |

| Work Model |

AC Servo Drive |

| Chip System |

Double Row Spiral Chip System |

| Max Working Speed X/Y/Z(mm) |

20/20/10m/min |

| Max Rapid Speed X/Y/Z(m/min) |

35/35/12m/min |

| Positioning Accuracy X/Y/Z(mm/m) |

0.025/0.025/0.015mm/m |

| Repeatability X/Y/Z(mm/m) |

0.013/0.013/0.001mm/m |

| Air Pressure (kgf/cm2) |

≥0.06 kgf/cm2 |

| Total Power (KVA) |

21KVA |

| Gross Weight (T) |

13.5T |

| Layout Szie (mm) |

5700*4800*4000mm |