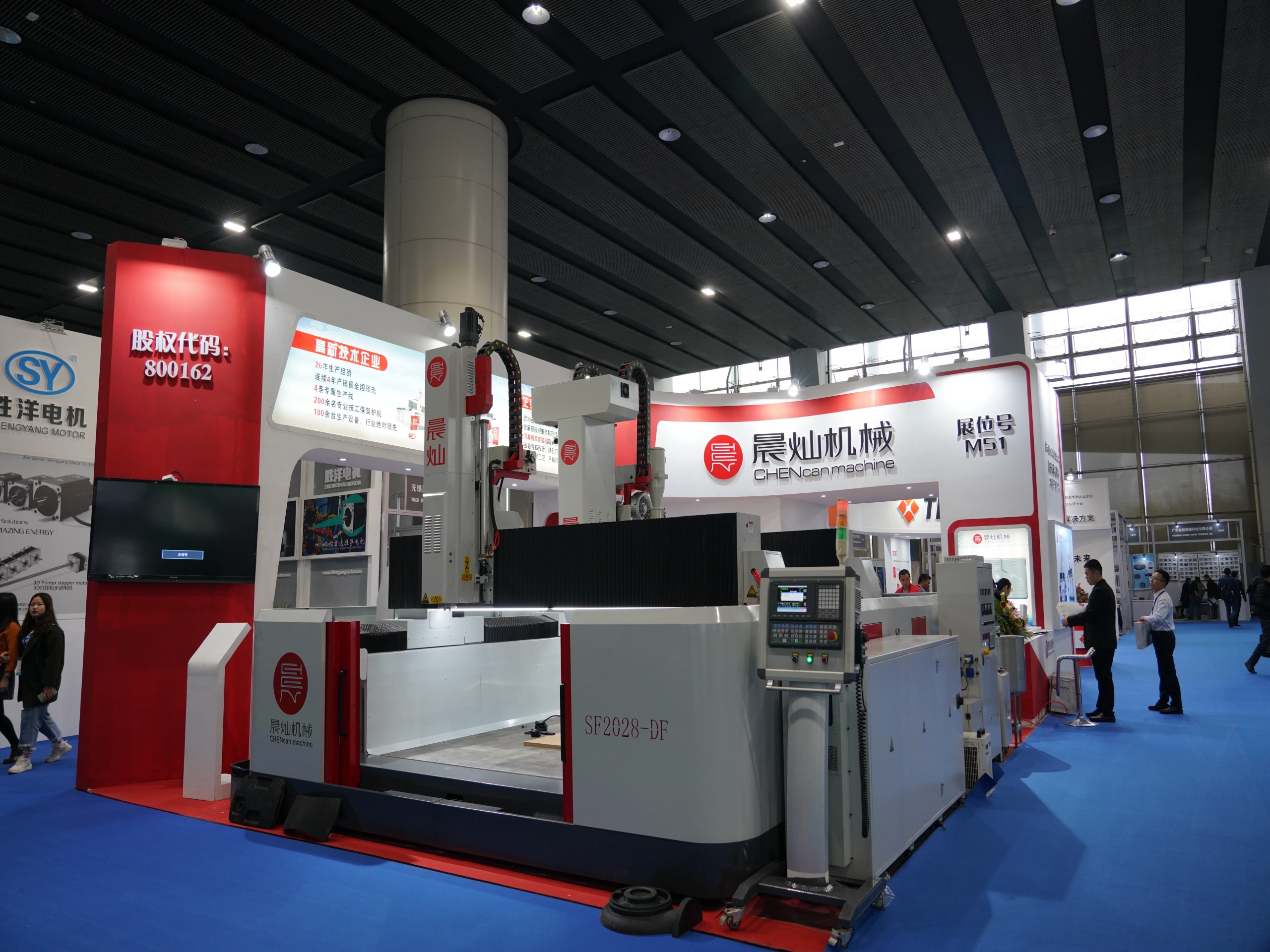

Core Advantages of High Precision CNC Pattern Milling Machine for Foundry Industry:

The machine with exceptional load capacity, featuring a high-rigidity cast iron structure and reinforced guide rails, ensuring stable loading of heavy workpieces. Even when cutting high-strength metals like steel and iron, it maintains machining stability and avoids vibration-induced precision deviations. Equipped with a high-speed spindle and optimized feed system, it increases machining speed by over 35% compared to traditional equipment. Three axes, equipped with grinding ball screws, achieve repeat positioning accuracy of ±0.01mm, ensuring machining precision and surface finish for molds made of various materials, including aluminum alloys, aluminum profiles, copper and other software metal materials.

Features of High Precision CNC Pattern Milling Machine for Foundry Industry:

1. Imported heavy-duty ball guides are standard on the X/Y/Z axes. The track surfaces undergo high-frequency quenching, resulting in a friction coefficient as low as 0.008 while ensuring rigid support. The lead screw utilizes a C3-grade ground nut drive mechanism with a pre-tension of 15% of the screw’s rated dynamic load, completely eliminating backlash. High-quality couplings ensure motor-screw coaxiality error of ≤0.002mm, resulting in a transmission efficiency exceeding 98%.

2. Auto Lubrication and Maintenance Warning: Auto lubrication system, coupled with an on-board lubrication pump, ensures uniform lubrication of key components such as the guide rails and lead screw. Oil level and pressure monitoring provides automatic oil shortage alarms.

3. The spindle nose is equipped with an air curtain dust control and a central air blower, with air pressure reaching 0.6MPa, effectively preventing chips and coolant from entering the spindle, extending bearing life by over 30%.

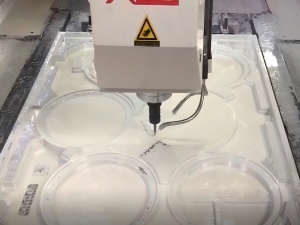

4. Multi-Working Condition Adaptability: The worktable with T-slot matrix design, and with optional hydraulic floating clamps or electromagnetic chucks, it can quickly adapt to workpieces of varying sizes and shapes, achieving a repeatability of ±0.003mm.

5. CE standard protection design, making the machine be suitable for complex workshop environments such as dust and coolant splashes. The electrical cabinet with a constant temperature device, ensuring stable operation in the temperatures ranging from -5°C to 40°C, meeting the production needs of factories in various regions.

6. Warranty time: for whole machine we provide 2 years warranty time and lifetime technical support. Customer could choose regular after-sales calibration service, which use professional equipment such as laser interferometers and ball bars, we re-test and compensate for screw pitch errors, guide rail parallelism, etc., to ensure that the accuracy of the equipment is not reduced after long-term use.

High Precision CNC Pattern Milling Machine for Foundry Industry & Materials:

| Industry |

Material |

| Automotive Industry |

Aluminum Alloys, Aluminum Profiles |

| Railway Industry |

Copper and others soft metal |

| Aerospace |

Wood, MDF, PVC, Foam, MDF, Plastic |

| Casting Patterns and Moulds |

Composites materials |

Technical Parameters of Heavy Duty Gantry Milling Machine for Mold Making:

| Model |

SM3025 |

| Table Size |

3000*2500mm |

| Working Area |

X:3000 Y:2500 Z:800mm |

| Distance between spindle nose and work table |

100-700mm |

| Work Table type |

Iron Table with T slot |

| T slot |

22-210-10 |

| Max.Woke Table Load |

1.6T |

| Spindle Type |

Powerful Mechanical ATC Spindle |

| Spindle Motor Power |

10Kw big power servo spindle motor |

| Max. Spindle Motor Torque |

47.8 N.m |

| Spindle Speed |

12000rpm/min |

| Spindle Cone |

BT40 or BT50 as optional |

| Spindle Cooling Type |

Oil Cooling |

| Tool Magazine Type |

Carosel tool magazine |

| Tool Magazine Capacity |

12 pcs |

| Max Tool Diameter |

Φ65mm |

| Max Tool Length |

250mm |

| Max Tool Weight |

8KGS |

| Control CNC |

HNC System |

| Drive System |

HNC servo motor and drivers |

| Drive Type |

XYZ: Grinding ball screws |

| Pront Protective Door |

Yes |

| Work Model |

AC Servo Drive |

| Chip System |

Double Row Spiral Chip System |

| Max Working Speed X/Y/Z(mm) |

20/20/10m/min |

| Max Rapid Speed X/Y/Z(m/min) |

35/35/12m/min |

| Positioning Accuracy X/Y/Z(mm/m) |

0.025/0.025/0.015mm/m |

| Repeatability X/Y/Z(mm/m) |

0.013/0.013/0.001mm/m |

| Air Pressure (kgf/cm2) |

≥0.06 kgf/cm2 |

| Total Power (KVA) |

21KVA |

| Gross Weight (T) |

14.5T |

| Layout Szie (mm) |

5700*5300*4000mm |