Styrofoam mold carving machine is a high-precision and high-efficiency machine. Regular maintenance is important to keep its accuracy and extend its lifetime.

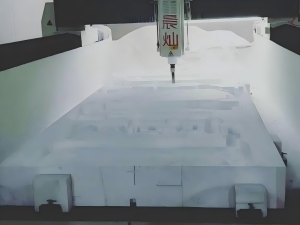

1. Dust Cleaning: Daily clean the work table after one day work, keep the appearance of thesurface of the mold cnc router, and prevent dust and debris from entering the equipment.

2. Parts Maintenance: Regularly check the various parts of the surface of the mold cnc router, including guide rails, transmission systems, spindles, collet, etc., to ensure that they operate normally, and find and solve problems in time.

3. Lubrication Maintenance: mold cnc router adopt auto lubricate system, which will lubricate the various parts of the machine according to the requirements automatically, but need to check the oil level in pump regularly.

4. Temperature Control: Regularly check the working temperature of the mold cnc router to avoid high temperature affecting the machine’s operation, and handle abnormal temperature problems in time.

5. Cooling System Maintenance: mold cnc router adopt water chiller, the cooling system must be used during the process to ensure the heat dissipation of the spindle and tool, reduce tool wear and extend the life of the equipment.

6. Regular Calibration: Calibrate the machine regularly to ensure the processing accuracy and stability of the mold cnc router.

7. Safety Protection: Ensure the safety protection around the machine are good to ensure the operator safety and avoid accidents.

8. Timely Maintenance: When machine collsion or problems are found, pleae contact the professional maintenance personnel in time for repair to avoid the problem from affecting the normal use of the machine.

In the end, mold cnc router require regular maintenance and attention to keep the machine in good condition and improve its accuracy, efficiency and lifetime.