Picking the right machine for crafting molds in industries like cars, planes, or casting is a tough call. You want gear that nails tricky shapes without draining your wallet. Prices for high-precision mold making machines swing a lot. What makes them pricey? Stuff like size, tech, and support plays a big part. For 27 years, CHENcan has been a solid pick for CNC solutions. They’re based in Dezhou, Shandong, with two huge factories covering 60,000 square meters. Their crew of 270, with 10% working on new ideas, has helped over 12,000 customers in 70 countries. Their shops have ISO9001 and CE stamps. Machines of CHENcan mix quality with fair prices. This post digs into why these machines cost what they do. It shows how you can grab a good deal for your shop. Ever wonder what’s worth the extra bucks? Let’s break it down.

What Is High-Precision Mold Making and Why Does It Matter?

You’re probably after machines that churn out perfect molds for things like car parts or movie props. High-precision mold making is key for nailing exact shapes. It’s a game-changer for keeping your products top-notch. With over 130 patents and ties to big names like Tsinghua University, these machines are built to handle tough jobs across the world.

Tight Tolerances

Molds need to hit super-precise specs, like ±0.015 mm, for casting or plane parts. You can’t mess around with sloppy fits.

Big Industry Impact

These molds make cars, plane blades, and even foam sculptures for film sets run smoother. They save time and boost quality.

Trusted Know-How

Years of work with 12,000+ clients mean machines that fit small shops or big factories. You get reliable gear every time.

What Key Components Influence Mold Making Machine Costs?

Ever notice how some machines cost way more than others? It’s all about what’s inside. The parts, like the frame or spindle, jack up the price. But they also make the machine better at tackling your projects. Building everything in-house, like in those 60,000-square-meter Shandong factories, keeps prices down while keeping quality high.

Bigger Size, Bigger Price

Machines with wide ranges, like 2,000 mm on the X-axis, need more steel and design work. That pushes the cost up.

Strong Spindles

Spindles with 9 kW power hitting 24,000 rpm cost extra. But they cut fast and handle tough stuff like a champ.

Tough Materials

Cast iron tables and strong steel beams last longer. They’re pricey but keep your machine steady for years.

How Do Axis Configurations Affect Pricing in Mold Machines?

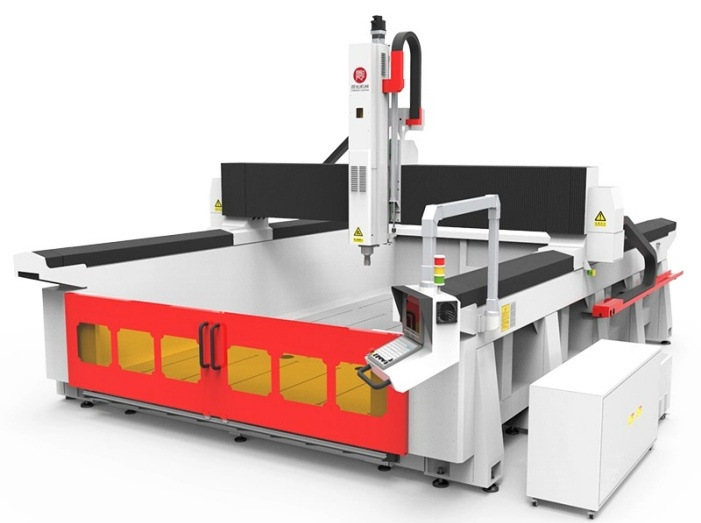

Wonder why one machine costs double another? The axes make a huge difference. You’ve got to match the machine to your mold’s complexity. A 3-axis setup works for simpler jobs, while more axes handle fancy designs. The 3 Axis CNC Mold Machine for EPS Foam Mould Making is a wallet-friendly pick for foam molds.

Three-Axis Basics

Three axes give you solid control for simple molds. They keep prices low and get the job done.

Five-Axis Costs More

Rotational A and C axes add complexity. They cost more but cut tricky shapes like nobody’s business.

Custom Fits

You can tweak the axes to match your needs. This balances cool features with what you can afford.

What Role Does Technology Integration Play in Cost Variations?

Fancy tech can spike a machine’s price. You want slick features, but they don’t come cheap. Smart controls and automation make work easier, yet they bump up the upfront cost. Over 100 million yuan spent on new ideas means these machines pack modern tech without crazy prices.

Smart Controls

Systems like Siemens 840D guide the tool perfectly. They’re a bit expensive but make cuts super smooth.

Tool-Swapping Systems

Automatic tool changers, like 8-tool setups, speed things up. They add to the price but save you time.

Software That Works

Good CAD/CAM links cut down on mistakes. They cost a bit more but save you headaches later.

How Does Material Compatibility Impact Machine Pricing?

When you’re shaping molds from foam, wood, or composites, the machine’s ability to switch materials matters. You need gear that handles different stuff without losing accuracy. That flexibility can cost extra, but it’s worth it for mixed projects. The Wood Sculpture CNC Foam Ring Pattern Making Machine shines for foam and wood in pump or valve molds.

Foam and Wood Ease

Spindles made for soft stuff like EPS foam keep prices fair. They cut clean without breaking the bank.

Tough Composites

Machines for composites or aluminum need stronger parts. That extra strength raises the price tag.

All-Purpose Design

Handling lots of materials adds design costs. But it lets you take on more kinds of jobs.

What Maintenance and Support Factors Contribute to Total Ownership Costs?

You might eye the price tag first, but what about the long run? Maintenance and support can hit your wallet hard if you’re not careful. A machine that’s easy to fix and backed by good help saves cash over time. Lifetime support and a 1-2 year warranty keep your shop running without surprise bills.

Warranty Coverage

Long warranties add a bit to the price. But they save you from big repair costs down the line.

Easy Parts Access

In-house spare parts and 40 technicians mean quick, cheap fixes. You’re back to work fast.

Training and Setup

On-site help gets you started quick. It cuts downtime and keeps your projects on track.

Why Choose These Machines to Manage Your Mold Making Costs?

You want gear that’s dependable, fast, and doesn’t cost a fortune. High-precision mold machines from a trusted name deliver all that. They’ve worked with folks from Colombia to China, proving they’re up for any job. The CNC Mold Machine for Mould Casting Industry is great for casting molds, giving you accuracy at a decent price.

Built to Last

Over 130 patents and 27 years of know-how mean machines that don’t quit. You save on repairs.

Worldwide Support

Offices in four countries and clients in 70 markets mean you’re covered, no matter where you are.

Good Value

These machines mix high precision with fair prices. They fit all kinds of budgets.

How Can You Keep Costs Down When Buying a Mold Making Machine?

Ready to grab a mold making machine? You want the best deal possible. By picking the right specs and exploring budget-friendly options, you can get a machine that fits your needs and wallet. Reach out to the team at the team at CHENcan for a custom solution. It’s a no-brainer to talk to experts first.

Know Your Needs

Pick a machine that matches your job size and materials. Don’t pay for stuff you won’t use.

Look at Total Costs

Check operating costs, not just the price. Energy-saving designs cut your bills over time.

Get a Custom Build

Work with pros to tweak the machine for your goals. You get what you need without extra costs.

FAQ

Q1: How do axes change the price?

A: Three-axis machines are cheaper for basic molds. Five-axis ones cost more but tackle complex shapes.

Q2: Are maintenance costs a hassle?

A: Not much. In-house parts and lifelong support keep fixes cheap and quick.

Q3: Can you tweak machines for certain jobs?

A: Yup. Machines are built for fields like cars or casting, matching your exact needs.