The wind energy sector is booming in 2025, but building massive 100-meter turbine blades creates a nightmare for manufacturers. If your molds have even tiny defects, you face millions in repair costs and wasted materials.

Large-format 5-axis CNC machining is the dominant technology for wind turbine fabrication today. It offers the speed, rigidity, and RTCP precision needed to machine 30-meter+ blade molds from epoxy and composites without the errors common in older 3-axis systems.

I have spent over 27 years at CHENcan helping shops solve these exact problems, so let me explain why this tech is your best path forward.

LOOP START

What Are the Key Challenges in Wind Turbine Part Fabrication in 2025?

Turbine blades keep getting longer to capture more wind, yet traditional machining methods struggle to handle these massive sizes. Failing to adapt leads to poor aerodynamics, structural weaknesses, and lost contracts.

The main challenges include managing ultra-large scales where small angle errors multiply, achieving perfectly smooth surface finishes on composite materials, and meeting strict government deadlines. Manufacturers must overcome these hurdles to maintain efficiency and profitability in a competitive market.

In my two decades of experience, I have seen the wind industry change drastically. The challenges we face in 2025 are unlike anything before. We are no longer just making big parts; we are making gigantic, aerodynamic structures that must be perfect. If you are using old 3-axis setups or simple gantry systems, you are likely dealing with deep scratches and bumpy surfaces. This forces your team to spend weeks on hand fixes, which kills your profit margins.

To understand why this is so hard, we need to look at the specific hurdles that factories face today.

| Challenge Area | The Specific Problem | The Consequence |

| Ultra-Large Scale | Molds now extend to 31 meters or longer. | Small angle mistakes grow into shifts of several millimeters, ruining the blade’s wind-catching ability. |

| Material Demands | Epoxy, putty, foam, and composites need smooth surfaces. | Rough spots weaken the structure, leading to safety risks in harsh offshore conditions. |

| Tight Deadlines | Testing costs a fortune and government targets are strict. | Any delay in mold creation can stop a whole wind farm setup for months. |

When you look at these factors, it becomes clear that precision is not just a nice-to-have feature; it is the difference between a working turbine and a piece of scrap metal. The sheer size of these molds makes every cut critical. Without the right tools, your final product will suffer from poor fit and reduced efficiency, which is something no energy company will accept.

Why Does 5-Axis CNC Machining Dominate the Wind Energy Sector?

Using basic 3-axis machines for complex curved blades results in rough surfaces and endless hours of manual sanding. This bottleneck kills your production speed and hurts the final quality of the blade.

Real 5-axis CNC equipped with RTCP (Rotational Tool Center Point) dominates because it moves the tool along complex curves simultaneously. This technology ensures superior accuracy, high-speed processing up to 60 m/min, and flawless finishes on epoxy molds that 3D printing cannot yet match.

You might wonder why we cannot just use 3D printing or stick with cheaper 3-axis machines. The answer lies in the geometry of wind turbine blades. These blades have complex, flowing aerodynamic shapes that twist and turn. A 3-axis machine cannot reach these angles without stopping and repositioning the part, which ruins accuracy.

True 5-axis CNC equipped with RTCP control is the game changer here. Unlike “3+2” setups that just hold an angle, true 5-axis lets all axes move together at once.

- Superior Accuracy:RTCP holds the tool tip exactly where it needs to be. Even when the machine head rotates, the tip stays on the path. On a 30-meter piece, this stops errors from building up across great distances.

- High-Speed Performance:These machines are beasts. With spindles reaching 24,000 RPM and movement speeds of 60 meters per minute, you can cut processing time in half.

- Versatility:While 3D printing is cool for small tests, it lacks the speed and toughness for full-scale blade molds. 5-axis machining works wonderfully on epoxy and composite molds, leaving a surface that is often ready to use right away.

I have seen factories try to cut corners with lesser technology, but they always come back to 5-axis. It provides the proven strength and consistency required for critical wind energy jobs. It is the only way to get the job done right the first time.

How Large-Format 5-Axis CNC Overcomes Scale Challenges in Blade Mold Production?

Machining a 30-meter mold is risky because a single crash or alignment error can ruin the entire expensive workpiece. Standard machines simply lack the stability and reach to handle such massive surface areas safely.

Large-format 5-axis machines overcome scale issues through advanced gantry designs with heavy-duty frames and long travel distances up to 31 meters. These systems use high-quality rack-and-pinion drives to maintain positioning accuracy of ±0.04 mm/m across the entire workspace.

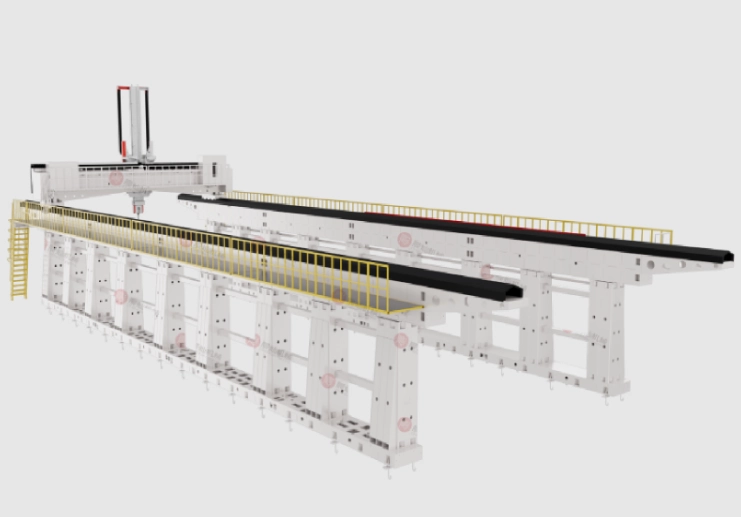

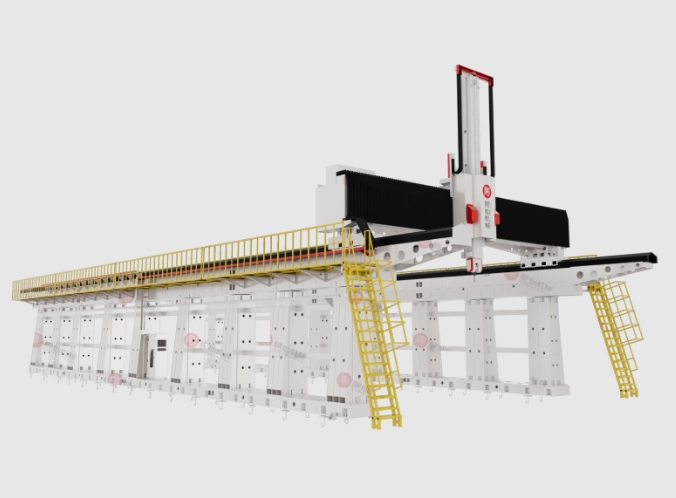

When we talk about “large format,” we are not talking about a standard room-sized machine. We are talking about massive industrial equipment designed to span the length of a warehouse. At CHENcan, we developed the 31 Meter High Speed 5-Axis Machining (Model SF31090-5S) specifically for this purpose.

Standard machines cannot cover the needed area. If you try to stitch together a mold from smaller sections, you introduce weak points and seams. A dedicated large-format machine solves this through sheer size and rigid engineering.

Here is how these machines handle the massive scale:

- Advanced Gantry Designs:The machine uses a bridge-style structure that moves over the part. This provides the stability needed to absorb vibrations, even when the cutting head is far from the center.

- Optimized Motion Control:We use heavy-duty ball screws and rack-and-pinion systems. This ensures that even when the machine moves fast, it does not shake or lose its place.

- Powerful Spindles:Using components like the Italy HITECO 15 kW spindle ensures that the machine has the torque to cut through tough composite materials without slowing down.

To give you a clearer picture of the capabilities, look at the specs of our custom wind turbine equipment:

| Feature | Specification | Why It Matters |

| Work Area | Up to 30m x 8m x 4.6m | Covers the entire blade mold in one setup. |

| Rotary Axes | ±120° A-axis, ±360° C-axis | Allows the tool to reach every curve and undercut. |

| Speed | 60 m/min rapid travel | Finishes detailed molds in just one night. |

This equipment allows you to manage epoxy and putty materials expertly, delivering outstanding surface quality that cuts down on extra finishing work a great deal.

What Real Benefits and ROI Can You Expect from Advanced CNC in Wind Fabrication?

Sticking to old fabrication methods drains your budget through high tooling costs and slow turnaround times. You cannot afford to lose money on wasted materials or delayed projects in this fast-paced industry.

Investing in advanced CNC equipment delivers a 60-90% reduction in tooling costs and drastically cuts production time from weeks to days. This efficiency boosts your return on investment by allowing you to take on more projects and deliver higher-quality blades faster.

I talk to business owners all the time who are scared of the initial price tag of a large 5-axis machine. But you have to look at the Return on Investment (ROI). In the wind industry, time is literally money. If you can produce a mold in three days instead of three weeks, your capacity skyrockets.

From our work with customers, many recover their investment in just months. Here is where the value comes from:

- Significant Cost Savings:You see massive reductions in tooling expenses compared to old manual ways. Quicker testing lets your design teams refine blades without huge delays. This lowers the overall project cost and helps you stay within budget.

- Efficiency Gains:Because the machine leaves a superior surface finish, you do not need a team of ten people sanding the mold by hand for a week. A single machine manages tough shapes that once required groups of workers. Production flows much smoother.

- Long-Term Reliability:These machines are built like tanks. They offer years of dependable service even under heavy daily use.

Furthermore, more precise blades perform better in the field. When your molds are accurate, the turbines generate more power. This builds your reputation in the industry. Clients will trust you with their biggest contracts because they know you can deliver consistent quality. It is a cycle of growth that starts with having the right equipment.

Why Choose CHENcan for Your Wind Energy CNC Solutions?

Finding a reliable machine partner who understands the specific needs of wind energy can be frustrating and confusing. Many suppliers lack the specific experience or global support network to keep your production running smoothly.

CHENcan is the ideal choice because we have over 27 years of experience and support clients in 70+ countries specifically in wind blade mold manufacturing. We offer custom 31-meter 5-axis solutions, expert installation, and 24/7 global technical support to ensure your success.

I am proud to say that CHENcan is not just a machine seller; we are a partner in the renewable energy revolution. We focus strongly on new energy fields, and our equipment is trusted by clients all over the world for composite wind power mold needs.

What sets us apart is our deep understanding of the application. We know you are cutting epoxy, foam, and putty. We know you need dust collection that actually works. We back our machines with over 130 patents and constant research and development.

- Global Support:We have teams in China, the United States, India, and Russia. If you have an issue, we can provide quick assistance wherever you are.

- Tailored Designs:We do not just sell stock models. We provide flexible custom setups to fit your factory floor and your specific blade designs.

- Full Service:From the moment you contact us, we offer personalized quotes, expert installation at your site, and thorough training for your staff.

We also make it easy to get answers. If you are wondering about materials, our machines handle epoxy and composites perfectly. If you are worried about lead times, our high-speed systems cut them sharply. We are here to help you thrive in the growing renewable energy market. You can reach out to us anytime for a conversation about how we can help upgrade your production line.

Conclusion

In 2025, large-format 5-axis CNC machining is the only viable choice for wind turbine fabrication, offering unmatched speed and precision. CHENcan’s 31-meter systems provide the reliability you need to succeed.