The core of CNC machinery maintenance is “regular inspection, lubrication as needed, cleaning and dust prevention”, which can effectively extend the life of the equipment, avoid precision degradation and sudden failures.

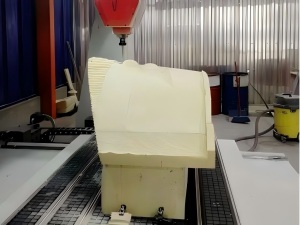

1. Dust Cleaning: Daily clean the work table after one day work, keep the appearance of the surface of the axis 5 cnc router, and prevent dust and debris from entering the equipment.

2. Temperature Control: Regularly check the working temperature of the 5 axis cnc carving machine to avoid high temperature affecting the machine’s operation, and handle abnormal temperature problems in time.

3. Regular Calibration: Calibrate the machine regularly to ensure the processing accuracy and stability of the 5 axis gantry machine.

4. Safety Protection: Ensure the safety protection around the machine are good to ensure the operator safety and avoid accidents.

5. Follow the Instructions manual: Maintenance requirements for different brands and models of 5 axis cnc router. The included maintenance manual must be your primary guide.

6. No Illegal Operations: Do not clean the moving parts while the machine is running, and do not use water to clean the electrical parts of the equipment.

7. Record and Archive: Build a maintenance log, detailing the time, content, operator, and equipment status of each maintenance session to facilitate traceability and subsequent maintenance.