The core of CNC machinery maintenance is “regular inspection, lubrication as needed, cleaning and dust prevention”, which can effectively extend the life of the equipment, avoid precision degradation and sudden failures.

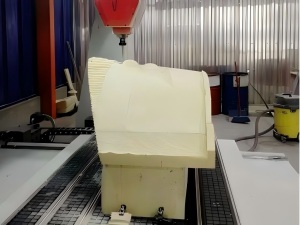

1. Dust Cleaning: Daily clean the work table after one day work, keep the appearance of the surface of the 5 axis cnc machine, and prevent dust and debris from entering the equipment.

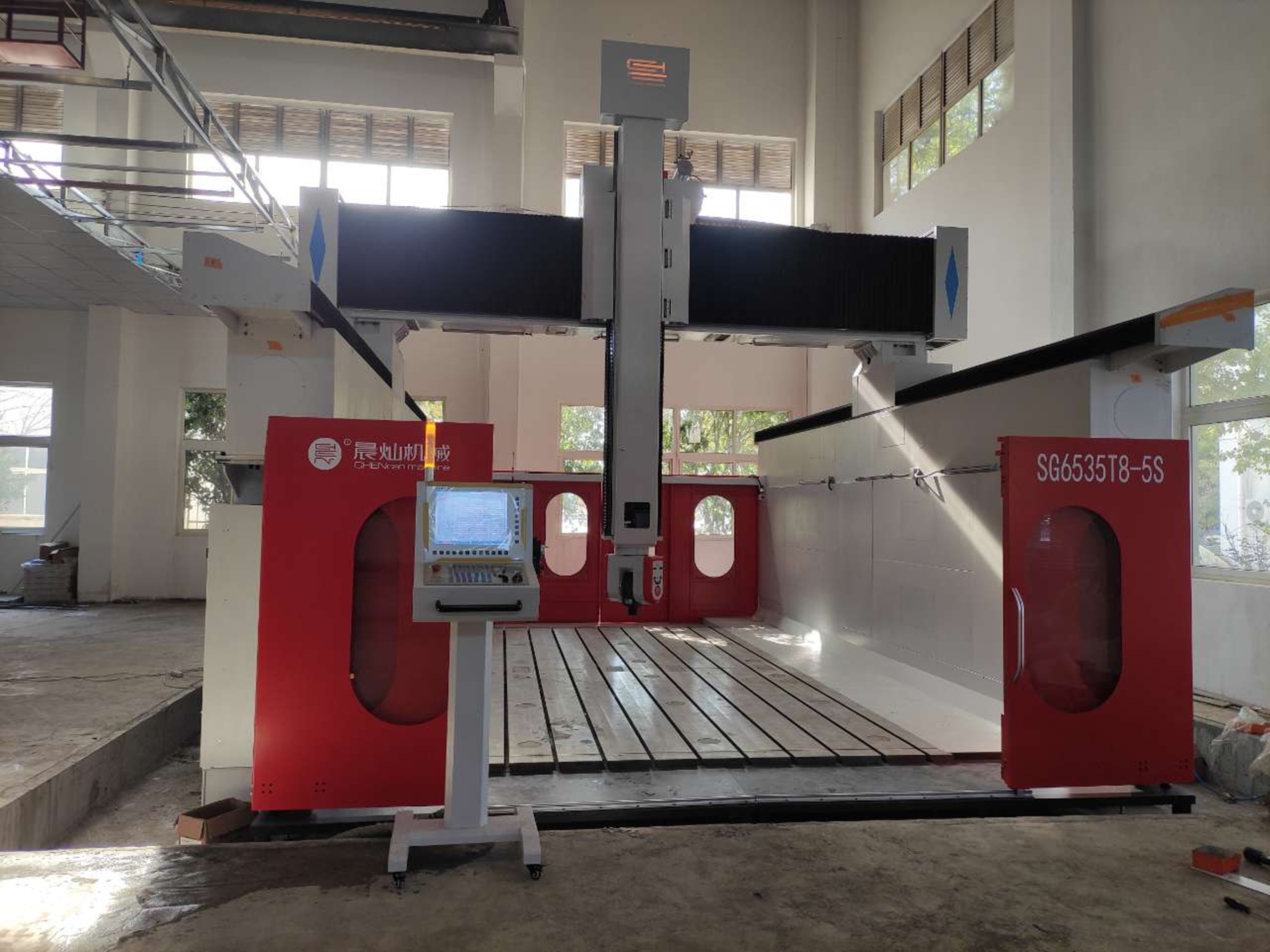

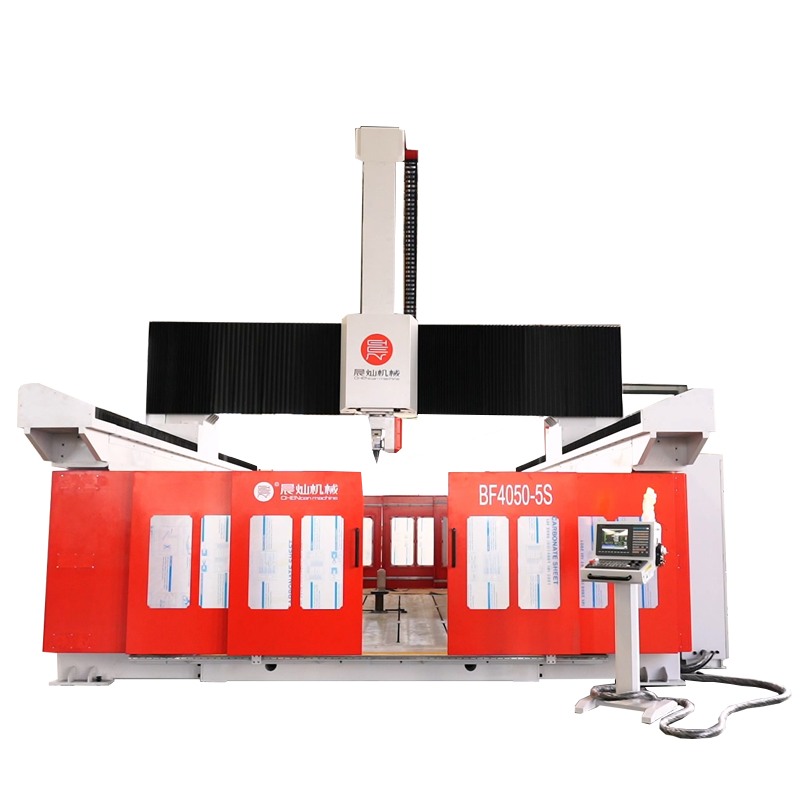

2. Parts Maintenance: Regularly check the various parts of the surface of the 5 axis cnc router, including guide rails, transmission systems, spindles, collet, etc., to ensure that they operate normally, and find and solve problems in time.

3. Lubrication Maintenance: 5 axis cnc router adopt auto lubricate system, which will lubricate the various parts of the machine according to the requirements automatically, but need to check the oil level in pump regularly.

4. Temperature Control: Regularly check the working temperature of the 5 axis cnc machine to avoid high temperature affecting the machine’s operation, and handle abnormal temperature problems in time.

5. الصيانة في الوقت المناسب: عندما يتم العثور على تصادم آلة أو مشاكل، يرجى الاتصال بموظفي الصيانة المهنية في الوقت المناسب لإصلاح لتجنب المشكلة من التأثير على الاستخدام العادي للآلة.

In the end, 5 axis cnc router require regular maintenance and attention to keep the machine in good condition and improve its accuracy, efficiency and lifetime.