Building boats in 2026 often still depends on old-fashioned manual ways in many workshops. These outdated approaches bring lengthy delays, steep expenses, and uneven outcomes that leave builders and customers equally frustrated. Affordable CNC routers now completely transform this picture by producing accurate foam plugs and molds in mere hours rather than dragging on for weeks.

I have followed the marine sector closely for many years. One company truly shines when it comes to bringing advanced technology within easy reach of everyday boat builders. Established in 1998, تشينكان has developed into a reliable global supplier with more than 27 years of expertise, helping over 12,000 clients across 70 countries. Their cutting-edge plants cover more than 60,000 square meters, supported by serious R&D investment that has produced over 140 patents. They focus strongly on marine applications, including successful yacht mold projects.

Why Are Boat Builders Still Stuck with Traditional Methods in 2026?

Many workshops continue to lean heavily on time-honored handwork even today, and this reliance creates unnecessary hurdles. Exploring the real drawbacks reveals why change feels urgent for staying competitive.

Traditional boat building usually begins with talented craftsmen patiently carving wooden patterns or plugs entirely by hand. This demanding task requires scarce skills and easily stretches over weeks for moderately sized pieces. Moreover, material expenses climb quickly because of costly hardwood blocks, and a single error often forces the entire process to start anew.

Such manual practices severely restrict growth potential. Builders frequently encounter inconsistent shapes that directly impact hydrodynamic efficiency. Additionally, any design adjustment demands complete recarving, which adds months to schedules and raises the risk of losing valuable contracts in a fast-moving market.

What Are the Major Challenges in Traditional Boat Construction Today?

Boat builders face tough obstacles when sticking to classic approaches, and these issues affect both daily operations and long-term success. Recognizing them clearly shows why many are ready for a practical upgrade.

Time-Consuming Processes Leading to Project Delays

Carving a single hull plug by hand typically requires two to four weeks of steady effort. Experienced workers invest countless hours in careful shaping and repeated sanding, which keeps projects on hold and often causes missed deadlines.

High Labor Costs and Skill Shortages in the Industry

Locating skilled carvers becomes increasingly difficult year after year. Salaries for true experts push costs higher, while training fresh talent demands months with no certainty of strong results.

Inaccuracy and Material Waste from Manual Methods

Small human mistakes commonly produce asymmetry or rough surfaces. Workshops end up discarding large amounts of expensive wood, and the finished vessels may suffer from extra drag that lowers speed and raises fuel consumption.

How Do Affordable CNC Machines Revolutionize Boat Hull and Plug Mold Making?

The move toward digital tools marks a genuine turning point for marine manufacturing, and affordable options make this shift realistic for almost any shop. Their advantages appear clearly in everyday boat and kayak projects.

The Shift from Manual to Digital Precision in Marine Manufacturing

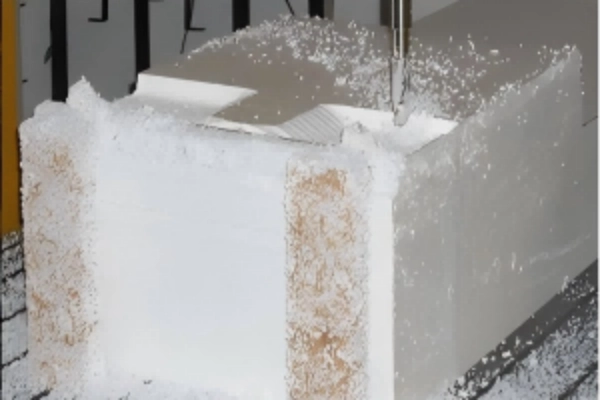

CNC technology swiftly converts 3D designs into tangible foam plugs overnight. Operators simply upload files, and the equipment accurately cuts complex curves that hand tools struggle to replicate reliably.

Key Benefits of CNC for Foam Pattern and Mold Creation

These routers handle EPS and Styrofoam with impressive efficiency, delivering exceptionally smooth surfaces ideal for fiberglass layering. They also slash material usage by more than 90% compared to wood while enabling rapid modifications whenever designs evolve.

Real-World Applications in Boat and Kayak Building

From compact kayaks to substantial yachts, CNC foam plugs speed up prototyping dramatically. Successful examples, such as yacht molds produced in Colombia, highlight how this method shortens production timelines remarkably.

Why Choose CHENcan’s Affordable 3-Axis CNC Solutions for Boat Projects?

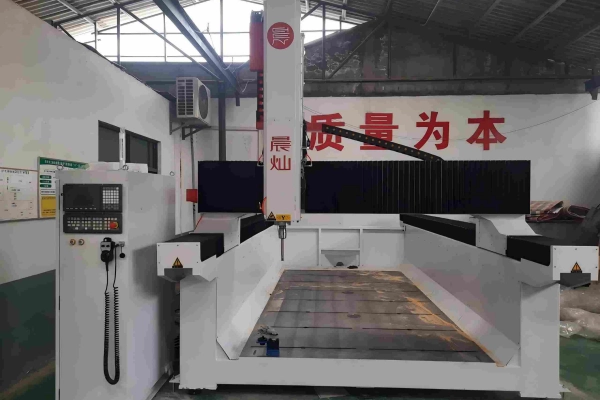

Selecting the right equipment partner truly matters, especially when budgets remain tight in marine workshops. CHENcan’s economical 3-axis lineup delivers reliable performance specifically suited for foam work in boat building, offering practical advantages that help builders stay competitive.

The company brings decades of expertise to the table, with in-house production ensuring consistent quality. Their focus on marine applications, including yacht plug processing, makes these machines a smart fit for hull and mold creation.

27 years of innovation: Starting from a small workshop in 1998, they pioneered high-speed machining of large non-metal materials and now serve global customers with offices in multiple countries.

Certified facilities: ISO9001 and CE standards cover all operations, with components built in-house for strict control.

Strong R&D backing: Over 270 professionals work across expansive production areas, supported by ongoing investment and more than 140 patents.

Marine expertise: Proven in international projects like yacht molds, providing reliable solutions for boat plugs.

These strengths combine to offer boat builders dependable, budget-friendly tools that handle real-world demands effectively.

Recommended Economic Models for Marine Foam Work

CHENcan’s accessible 3-axis machines target foam pattern creation perfectly, allowing builders to achieve big savings without added complexity. The lineup scales from small prototypes to large hulls, fitting various workshop needs.

| نموذج | Best For | Key Features | Main Benefits in Boat Building |

| BS1530 | Small boat plugs & prototypes | Compact size, dependable spindle for Styrofoam | Quick cuts in hours, low waste, repeatable accuracy |

| BS2040 | Mid-sized yacht molds | Expanded area for EPS foam, fast processing | Smooth finishes for composite layup, sharp cost drops |

| BS3060 | Large-scale hull patterns | Generous table for full plugs in one piece | Handles high volume economically, avoids joins |

This range provides flexible options that outperform traditional methods, helping builders produce better plugs faster and at lower expense overall.

Traditional vs. CNC: A Direct Comparison in Time, Cost, and Quality

Side-by-side evaluation makes the advantages obvious, especially for builders weighing their options carefully. Numbers and real results tell a compelling story.

Time Savings: From Weeks to Hours in Pattern Production

Average manual carving demands around 18 days of focused work. In contrast, CNC routinely finishes comparable foam patterns within 8 to 24 hours.

Cost Breakdown: 90% Reduction in Material and Labor Expenses

Wooden patterns often run into thousands of dollars. Switching to foam through CNC brings that down to just hundreds, eliminating premium wages for specialist carvers.

Quality Improvements: Precision and Consistency

Digital control guarantees perfect symmetry and flawless surface quality for better boat designs, resulting in vessels with superior hydrodynamic properties and real performance gains.

Conclusion

More builders worldwide recognize the practical edge these tools provide, and their experiences encourage others to follow suit. Support plays a vital role in smooth adoption.

Affordable CNC routers clearly surpass traditional methods across speed, expense, and final quality in today’s boat building. Begin with trusted economic models and enjoy immediate improvements. Reach out through the CHENcan contact page for tailored guidance and quotations.

أسئلة متكررة

Q1: How long does it take to machine a boat hull plug with affordable CNC?

A: Most patterns complete in 8 to 24 hours, far shorter than the weeks needed for manual carving.

Q2: Are these machines suitable for small boat builders?

A: Absolutely, entry-level models manage small to mid-size plugs effectively while remaining easy on the budget.

Q3: What materials work best for marine CNC patterns?

A: EPS and Styrofoam offer inexpensive, lightweight choices with outstanding surface results.

Q4: Can design changes happen quickly with CNC?

A: Simply update the digital file and remachine within hours, avoiding full recarving.

Q5: What ROI can builders expect from these machines?

A: Many recover the cost in under a year through dramatic material savings and accelerated production schedules.