FAQ for High Precision CNC Pattern Milling Machine for Foundry Industry

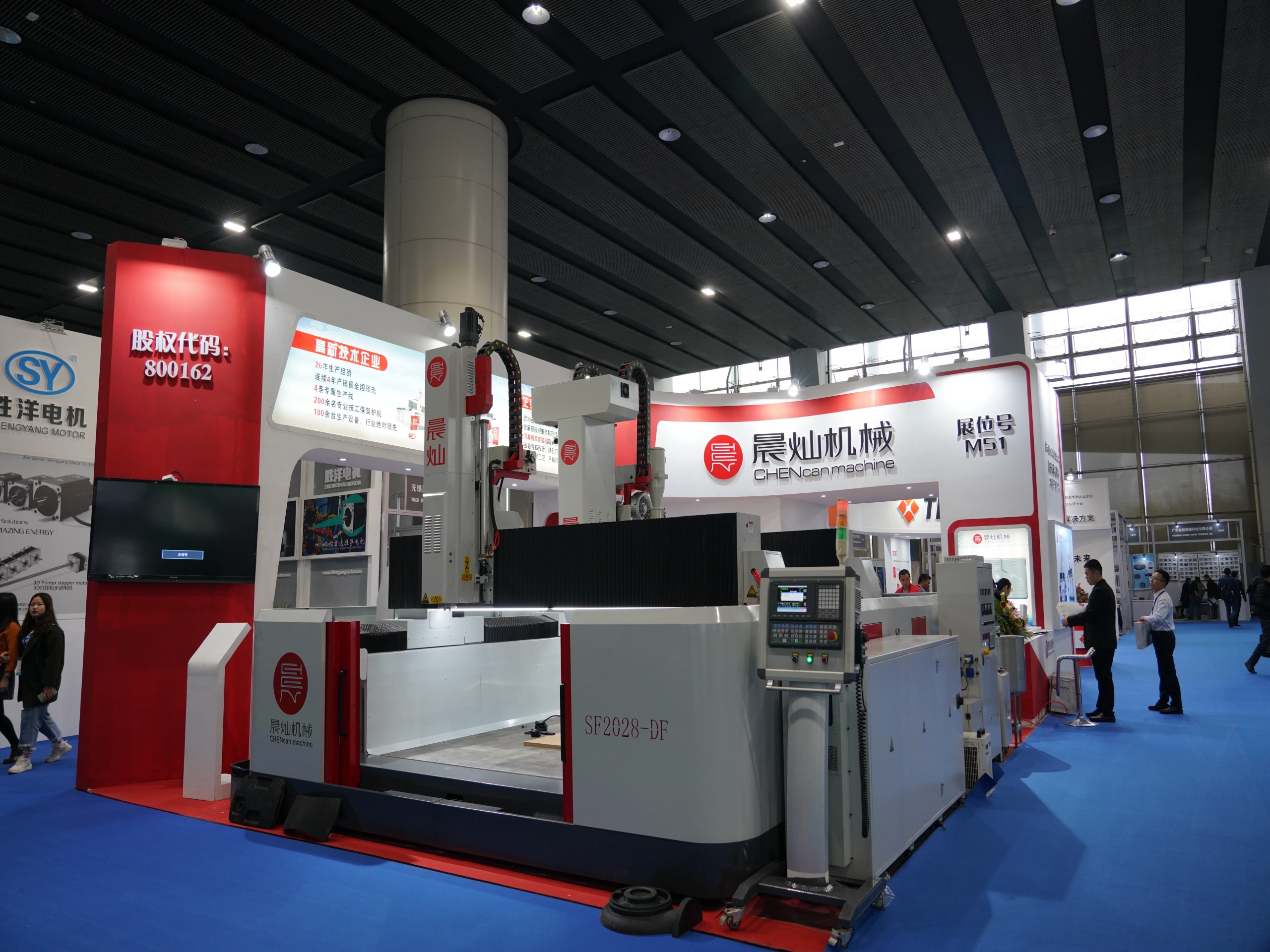

Q1. What are the core performance characteristics of the SM mold machining center?

The core characteristics are: “heavy-load stability, strong cutting performance, high speed, and high precision.”

Q2. In which industries does the SM mold machining center currently have advantages?

It break through the limitations of multi-material machining, demonstrating irreplaceable advantages, particularly in the lightweighting of automotive chassis and railway transportation applications.

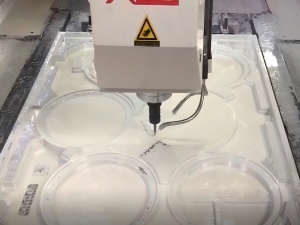

Q3. What materials and workpiece types does SM mold machining center process?

With a wide range of materials, such as cast steel, high-strength steel, aluminum alloys, and can reliably process both high-hardness and light metals.

Q4. How adaptable of SM mold machining center?

From small, precision components like axle boxes to long structural parts like body beams, it can efficiently process all, meeting the production needs of diverse scenarios.No need frequent equipment changes.

Q5. What value can SM mold machining center bring to the industry?

We primarily focus on high-end manufacturing, providing reliable processing support for key industries, such as automotive chassis manufacturing and rail transit equipment manufacturing.

Q6. What are the industry benefits of SM mold machining center?

For industries requiring extremely high precision and stability, we provide more reliable processing solutions, helping companies improve product quality and reduce production risks.