Choosing between manufacturing processes is confusing. This confusion leads to costly delays and risks sinking your project budget before you even begin. Understanding their roles as partners unlocks efficiency.

The best process depends on your goal. CNC machining is ideal for creating the initial mold or pattern quickly and affordably. Injection molding uses a finished mold to mass-produce thousands of identical plastic parts. For making the mold itself, CNC is the starting point.

Many factories mistakenly see these processes as rivals. In reality, every single molded part you produce begins its life on a CNC machine. The real question for 2025 isn’t “which is better,” but “how do I use them together for the fastest, lowest-risk outcome?” As someone who has been in this industry for a long time with my company, تشينكان, I’ve helped thousands of customers navigate this. Let me break down how you can make the right choice for your next project.

What Actually is the Difference Between CNC Machining and Injection Molding?

You are planning a new part and get stuck on this basic question. Choosing the wrong path can waste your entire project budget and schedule. Let’s clarify their distinct roles.

CNC machining carves the mold or pattern from a solid block of material. Injection molding uses that finished mold to inject molten plastic and create thousands of identical parts. One process makes the tool, and the other uses the tool for mass production.

To help you plan better, let’s go deeper into what each process does. I see this distinction as the first step in creating an efficient production plan.

Injection Molding: For High-Volume Parts

Injection molding is a process for producing final plastic parts in large quantities. A finished metal mold is clamped shut. Then, molten plastic is injected under very high pressure into the mold’s cavity. The plastic cools, solidifies into the shape of the cavity, and the machine ejects a finished part. This cycle repeats very quickly. It is the best method for production runs of 10,000 to millions of identical items, like plastic containers or small electronic casings.

CNC Machining: For the Mold Itself

CNC machining creates the mold or pattern that will be used for casting. A CNC machine follows a digital design to cut away material from a solid block, creating the precise shape needed. This could be a metal mold for injection molding, or it could be a disposable foam pattern for lost-foam casting. In 2025, we see a huge trend where 73% of new molds start with CNC foam patterns first. This allows foundries to validate a design cheaply before committing to expensive tooling.

When is CNC Cheaper and Faster Than Making an Injection Mold?

Your project budget is tight, and your deadline is even tighter. A single expensive steel mold can kill a project before it even gets approved. CNC offers a much faster path.

CNC is cheaper and faster for prototypes and low-volume runs under 5,000 pieces. It is also the best choice for projects with ongoing design changes or for very large parts where a traditional injection mold would be incredibly expensive.

In my experience advising clients, the decision often comes down to three common situations. If your project falls into any of these categories, CNC is almost always the right answer to start.

Prototypes & Low-Volume Production

If you need fewer than 5,000 parts, the cost of creating a full, hardened steel injection mold is often more than the value of the entire production run. Instead, we can use CNC to machine a mold from a softer material like aluminum, resin, or a composite. This gets you high-quality parts in days, not the months it takes to get a traditional mold made.

Fast Design Iterations

Your design is still changing. You need to test, get feedback, and make adjustments quickly. Modifying a hardened steel mold is a nightmare. It can add thousands of dollars in costs and weeks of delay for even a small change. With CNC, we just adjust the digital file and machine a new pattern or mold. This allows you to make changes in hours, not weeks, at a very low cost.

Large, Cost-Prohibitive Parts

Think about parts like bathtubs, large boat hulls, wind turbine blades, or automotive body panels. An injection mold for something this big would cost hundreds of thousands, or even millions, of dollars. It’s just not practical. Instead, we use a large CNC router to machine a foam or composite master pattern. This pattern is then used to create the final part, drastically reducing the cost.

Why Are Foundries Switching from Wood Patterns to CNC Styrofoam Patterns in 2025?

Making patterns from wood is slow and requires highly skilled craftspeople. This old method makes you lose bids to faster, more modern competitors who can deliver quicker.

Foundries are switching because CNC foam patterns cut lead times from weeks to just hours. This method also reduces material costs by over 90% and produces a smooth surface finish ready for lost-foam casting, helping them win more contracts.

The shift away from traditional methods is happening fast. I recently visited a foundry in Turkey that made this switch, and the results were incredible. They are now quoting jobs faster and winning more business. Here is why this technology is a game-changer.

Drastic Lead Time Reduction

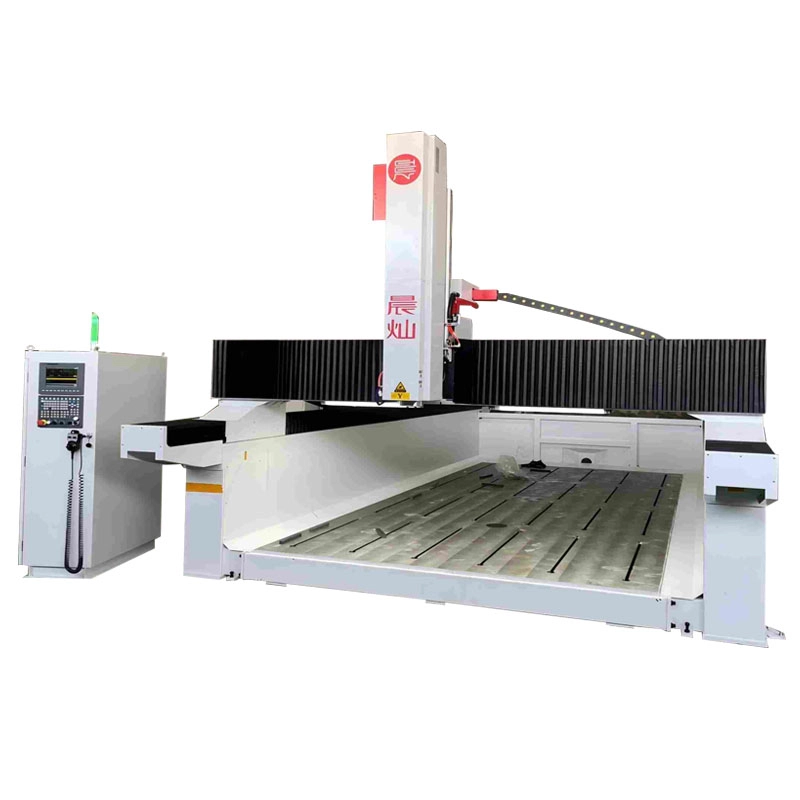

A skilled artisan might take two to four weeks to build a complex wooden pattern by hand. Our Styrofoam Mold Carving Machine, a large 4 by 3-meter router, can complete an even more intricate pattern overnight. We are talking about a lead time of 8 to 24 hours. This speed allows foundries to respond to customer requests almost immediately.

Superior Surface Finish

A CNC machine with a high-speed spindle running at 20,000 RPM can produce an incredibly smooth surface on EPS foam. The path of the cutting tool is optimized by software. This means the finished pattern is good enough for the lost-foam casting process right off the machine. It eliminates the slow, manual hand-polishing step that is always needed for wood patterns.

Massive Material Cost Savings

Wood is expensive, especially large, high-quality hardwood blocks. In contrast, EPS foam is very cheap. A single container of EPS beads can be expanded to create hundreds of large patterns. The material cost drops by as much as 90%. This is why our machines are becoming the top choice for foundries in markets like India, Turkey, Vietnam, and Eastern Europe.

Can CNC Directly Replace Injection Molds for Medium-Volume Production?

You need more than a few prototypes but are not ready for a full injection mold. This “in-between” volume of a few thousand to a hundred thousand parts feels like a production trap.

Yes, for medium volumes up to 200,000 shots, CNC can create “bridge” molds from advanced resin or composite materials. These tools are much faster and cheaper to make than steel molds and are reliable enough for serious production runs.

The idea of using non-steel molds for production used to be just for emergencies. Today, it is a smart strategy. We call it “bridge tooling” because it bridges the gap between prototyping and high-volume manufacturing.

The Power of Bridge Tooling

Instead of machining a pattern for a single-use casting, we use CNC to machine a mold directly out of a durable resin or composite block. With smart design, like adding cooling channels to manage heat, these molds can last a surprisingly long time. They can routinely produce 50,000 to 200,000 parts without failure.

A Real 2025 Case Study

I have a customer, a pump manufacturer in Turkey, who proves this works. They used to wait ten weeks for a traditional mold to be made. Now, they use one of our Mold CNC Routers to machine a resin pattern in just three days. With this pattern, they are achieving 8,000 castings every month. This new process completely changed their business.

Knowing When to Transition

Bridge tooling is perfect for the initial phase of production. You should make the jump from a CNC resin mold to a final, hardened steel mold only after two conditions are met. First, the part design must be completely stable and approved. Second, your monthly production demand consistently exceeds 20,000 units. Our Mold CNC Router, with its 7.5 kW automatic tool change spindle, is ideal for these interim tooling jobs.

How Much Money Can You Really Save with CNC Foam Patterns in 2025?

You have heard about the cost savings of switching from wood to foam, but you need real numbers. Without a clear return on investment, it’s hard to justify new equipment.

You can save over 90% on the cost of each pattern. For example, a wood pattern costing $4,500 and taking 18 days can be replaced by a CNC foam pattern for just $420, made in only 14 hours. The ROI on the machine is often less than 60 days.

The savings are not just theoretical. I’ve worked with dozens of foundries to calculate this, and the numbers are consistently amazing. Let’s break it down so you can see how it applies to you.

Cost Breakdown: Wood vs. EPS

Let’s use a real example: a pattern for a cylinder head.

- Traditional Wood Pattern: The cost for the wood and skilled labor is around $4,500. The time to build it is 18 days.

- CNC EPS Foam Pattern: The material cost is minimal. The machine time is about 14 hours. The total cost is around $420. That is a 91% cost saving on just one pattern. If you make hundreds of patterns a year, the savings add up very quickly.

Calculating Your Return on Investment (ROI)

A large 4 by 3-meter CNC foam router costs around $120,000. A typical foundry that previously outsourced or built 300 wood patterns a year can see a full return on this investment in under 60 days. After that, the machine is generating pure profit.

The Hidden Financial Gains

The direct cost savings are just the beginning. There are other hidden savings that boost your profit margins by 15% to 20%. You have fewer rejected parts from the casting process because foam patterns are more accurate. You have zero storage fees because you can machine a new foam pattern on demand instead of storing bulky wood patterns. And you get project approvals faster, which means you get paid sooner.

CNC Resin Mold or Traditional Mold – Which Wins in 2025?

You need a durable mold for a run of 50,000 to 200,000 parts. You naturally compare a CNC resin mold against a traditional steel mold for efficiency and durability.

For most medium-volume runs in 2025, the CNC resin mold is the clear winner. It cuts tooling costs by up to 60%, reduces lead times from months to days, and lowers cycle times by up to 40%, delivering a much faster return on investment.

In 2025, resin tooling is no longer just for prototypes. It has become a production workhorse, especially for industries like automotive interiors, sanitary ware, and consumer goods. We have customers now running 150,000 shots on our CNC-machined resin molds without failure. This is possible because modern CNC routers can machine complex, conformal cooling channels that make the resin tools highly efficient. The numbers speak for themselves.

| Item | Traditional Mold | CNC Resin Mold (2025) | Winner |

|---|---|---|---|

| Tooling cost | $45,000 – $120,000 | $18,000 – $48,000 | Resin |

| Lead time | 8-14 weeks | 5-12 days | Resin |

| Cooling time per cycle | 28-35 seconds | 18-22 seconds | Resin |

| Expected lifetime shots | 500,000+ | 100,000-250,000 | Traditional (only if >300k needed) |

| Design change cost | $8,000+ per revision | $800-$2,000 per revision | Resin |

| Typical payback period | 9-18 months | 3-6 months | Resin |

For 95 percent of medium-volume programs today, a resin mold machined on a CNC router delivers a lower total cost, faster speed to market, and much greater design flexibility.

Conclusion

Start with disposable CNC foam patterns for new designs. Move to machined resin molds for runs up to 200,000 shots. Use traditional steel molds only for fixed designs over 500,000 pieces.

Submit your 3D file now. We can provide a complimentary comparison of traditional tooling versus our modern CNC options within 24 hours. Many of our customers discover savings in the six figures on their immediate project.

أسئلة متكررة

Q1: How long does it take to get the first part using CNC foam patterns?

A: Machining the pattern takes 8 to 24 hours. Casting and finishing add another 2 to 3 days. Your total time to the first part is under one week.

Q2: Is resin durable enough for production molds?

A: Yes. With proper cooling channel design, modern resin molds can produce 100,000 to 300,000 parts in real-world production environments.

Q3: What is the typical payback time for a large foam CNC router in a foundry?

A: For an active lost-foam foundry, the payback period is typically 2 to 4 months. We often see it happen in under 60 days when replacing outsourced wood patterns.

Q4: My design changes every month. Which solution should I choose?

A: You should absolutely start with CNC-machined EPS foam or resin patterns. This allows you to make endless design changes quickly and at a tiny fraction of the cost of modifying a steel mold.