Running a pro 3D printer on a tight budget means more than just hitting the start button. You need to keep an eye on power use, material costs, regular fixes, worker hours, and how you tweak the print settings. In large factories where downtime equals lost money, every single factor adds up to the true hourly cost.

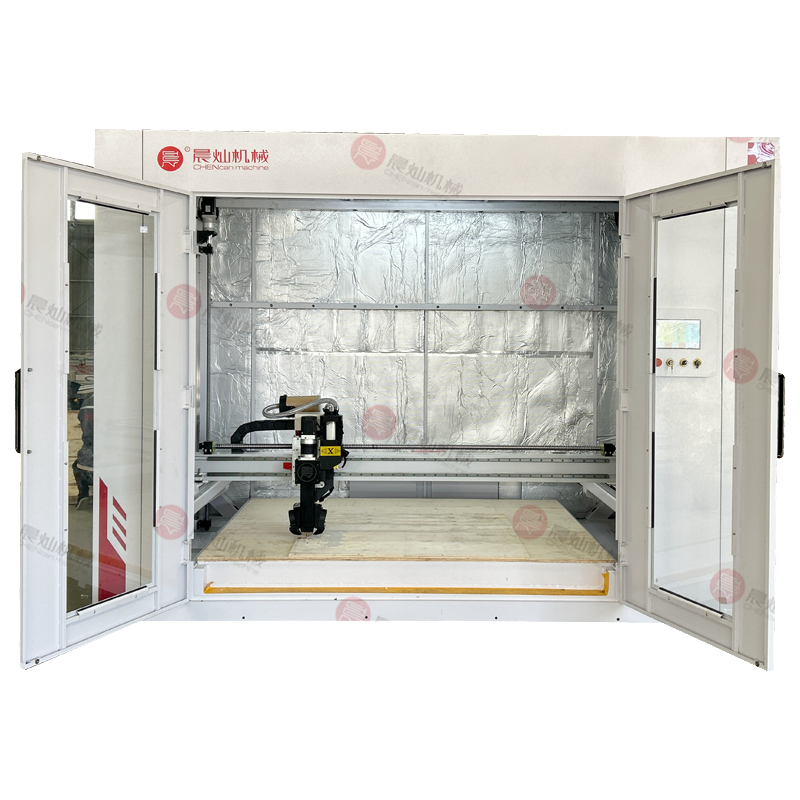

Not many companies deliver practical innovations quite like CHENcan kann. With over 27 years in the game, they’ve shipped high-quality CNC and 3D printing systems to more than 12,000 businesses across 70 countries. Their focus on in-house research, software tie-ins, and industry partnerships lets them create advanced machines.

What Factors Determine the Hourly Operating Cost of a Professional 3D Printer?

Several connected elements decide the cost per hour. Once you understand them, calculating the base rate becomes straightforward, and you can quickly spot ways to cut expenses.

Energy Consumption and Power Efficiency

Electricity often gets ignored in hourly breakdowns, yet the printer type, heating demands, and idle draw all play a big role.

Industrial printers differ widely in power needs based on size, materials, and technology. A massive machine handling high-temp polymers or composites will consume far more than a compact FDM unit. However, clever designs help. For example, the Hocheffiziente Partikel 3D Druck Form Ausrüstung uses targeted heat controls to minimize waste.

Track input power against output, and schedule prints during efficient windows—this alone can lower the cost per part. One auto shop I know shifted jobs to off-peak hours and watched their energy bill drop noticeably.

Material Usage and Waste Management

Materials usually claim the largest slice of the budget, from basic plastics to reinforced composites, so tight control is essential.

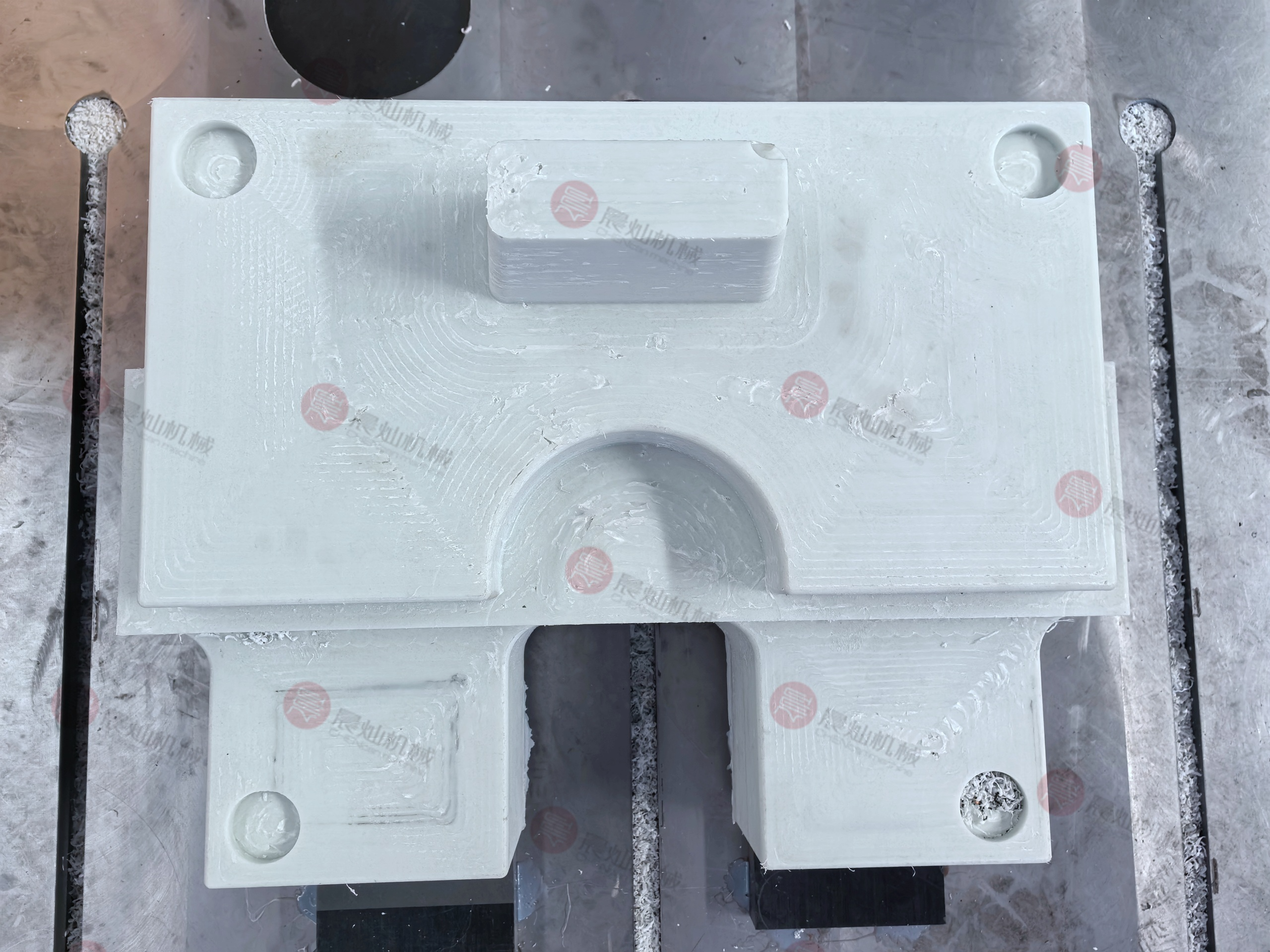

The DF Series Industrielle 3D-Druckmaschinen für Prozessmodelle support Near Net Shape production, using only what’s necessary and keeping waste minimal. This beats traditional subtractive methods, which can discard up to 90% of the raw stock—think of all that money in the scrap bin.

Recyclable composite pellets allow reusing leftovers or failed prints, building savings over time. Software-guided deposition improves precision and reduces unneeded supports, further conserving supplies.

Maintenance, Labor, and Downtime Costs

Every minute of downtime chips away at profits, whether from planned service or unexpected failures.

CHENcan emphasizes preventive care to avoid surprises, equipping machines with durable industrial parts that extend lifespan. Features like auto-lubrication and real-time diagnostics cut down on manual work.

Automation, such as self-leveling beds and material feeders, reduces operator involvement, which translates to lower labor costs per hour. In one local tool shop, switching to auto-feeders let a single worker manage three machines, boosting output without adding staff.

How Can Equipment Design Influence Operational Efficiency?

A thoughtful design does more than improve speed; it reduces overhead in energy, labor, and part replacements.

Integrated Energy-Saving Technologies

Modern pro printers include smart power features, like precise thermal regulation and efficient cooling to prevent excess draw during idle periods.

CHENcan machines feature optimized heating paths for consistent layer temperatures, especially useful in large-scale mold or prototype runs where stability prevents mid-print issues.

These elements ensure reliable performance over extended operations, which is critical in industrial settings where uptime directly impacts the bottom line.

Automation and Workflow Integration

Seamless links to digital systems minimize human errors and enhance repeatability. Automated bed leveling, nozzle calibration, and loading allow longer unattended runs.

CHENcan integrates hardware updates with software advancements, making it easy to connect to ERP or MES platforms for full production visibility. This setup lowers per-job labor and increases overall throughput—one prototyping firm linked theirs and saw errors drop by half, with jobs completing faster.

Component Durability and System Reliability

Constant part swaps can inflate costs quickly, but high-end builds withstand heavy use without frequent interventions.

CHENcan employs robust components for consistent multi-shift operation, avoiding mechanical failures or quality dips.

Is It Possible to Reduce Material Costs Without Compromising Quality?

Absolutely—through careful material choices, controlled deposition, and software-based design tweaks.

Smart Material Selection Based on Application Needs

Avoid jumping to expensive high-performance options; select based on the job’s specific strength and thermal requirements.

DF Series printers handle composites like PP, PC, ABS, and PA, common in automotive and aerospace. This flexibility lets you prioritize cost-effectiveness over brand defaults.

Precision Control Over Deposition Rates and Layer Thickness

Adjust layer heights to match part complexity or load needs, balancing integrity with material use.

Die 3D-Druckermaschine für die Herstellung von Formen offers detailed resolution controls for accuracy without excess feed—ideal for tooling or sculptural work.

Waste Minimization Through Design Optimization Tools

Incorporate CAD/CAM for pre-print simulations that catch issues like unsupported overhangs, eliminating extra supports or rework.

These adjustments reduce failed prints and boost yield. An aerospace team used simulations to trim waste by 40%, saving significant material on each batch.

How Does Print Speed Affect Cost-Efficiency in Industrial Applications?

Higher speeds increase output but must balance against quality and energy impacts.

Balancing Speed With Print Quality Requirements

Faster printing shortens cycles yet can affect surface finish or tolerances, depending on geometry.

Advanced slicing maintains quality at elevated speeds where possible, preserving durability.

Impact on Energy Use Per Unit Produced

Shorter jobs typically mean less energy per item, provided thermal systems keep up without spikes.

CHENcan’s efficient management supports high speeds with steady performance, optimizing both productivity and power costs. A drone parts shop cut their energy bill by 20% this way.

Influence on Labor Allocation and Machine Utilization Rates

Quicker prints reduce labor per job, and automation frees operators to oversee multiple units, raising utilization.

Smart scheduling maximizes throughput without straining equipment or staff.

Can Predictive Maintenance Lower Long-Term Operating Costs?

Definitely—it prevents major breakdowns, extends component life, and cuts overall expenses.

Real-Time Monitoring Systems for Early Fault Detection

Sensors track vibration, temperature, and extrusion in real time, alerting to issues before failure.

CHENcan machines connect to IoT tools for proactive notifications, allowing fixes without halting production.

Scheduled Maintenance Planning Based on Usage Metrics

Base service on actual data rather than fixed intervals, maximizing uptime. CHENcan logs enable precise planning; one plastics facility ran 15,000 hours before a simple belt replacement.

Spare Parts Availability and Technical Support Accessibility

Quick access to OEM parts and expert help minimizes downtime losses. CHENcan provides global support for fast diagnostics and replacements.

Why Should Businesses Consider Upgrading to High-Efficiency Models?

Upgrades bring lasting reductions in energy, breakdowns, and cycle times, plus smarter management.

Total Cost of Ownership Over Machine Lifetime

Initial outlay is offset by lower ongoing costs; over five to ten years, efficient models yield stronger returns.

Customization Capabilities Tailored to Industry Needs

Modular designs adapt to specific sectors like aerospace tooling or auto prototypes, enhancing output while meeting standards. A wind energy firm customized for blade molds, doubling production.

Access to Ongoing Technical Support and Innovation Pipeline

Continuous updates keep machines competitive, protecting investments and building team skills—essential in a rapidly evolving field.

FAQ (häufig gestellte Fragen)

Q1: How frequently should predictive maintenance be performed?

A: Use sensor data and usage logs to schedule just before wear peaks, avoiding unnecessary stops.

Q2: Is it possible to maintain high speed without compromising print quality?

A: Yes, with smart algorithms and thermal controls, top machines deliver fast results with accurate finishes.

Q3: How long does it take to see ROI from upgrading equipment?

A: Typically 12–24 months, driven by reduced energy, labor, reprints, and higher throughput; heavy-use auto parts shops might break even in nine months with round-the-clock operation.