Making a sculpture look real takes more than just art. It needs strong engineering. My company, CHENcan kann, provides the control you need to bring your detailed artistic visions to life.

To achieve realistic 3D sculptures, you must control the materials, mechanics, software, and finishing steps. Every detail matters. Our industrial-grade CHENcan machines give artists, designers, and engineers the precision needed for everything from fine art to large-scale landscape pieces.

I believe that creating a lifelike sculpture is a journey from a digital idea to a physical object. Getting every detail right, from the first layer to the final polish, requires a deep understanding of the technology involved. When every curve and texture is important, your entire setup must work together perfectly. Let’s explore how we make this happen.

What are the fundamentals of realistic 3D sculpture printing?

Your prints might be lacking that spark of realism. Small details look blurry and surfaces feel rough. I’ve found it comes down to three core pillars: materials, mechanics, and resolution.

Realism in 3D printing depends on three things. First is the material’s properties. Second is the machine’s mechanical stability. Third is the printer’s layer resolution. Getting these right is key to making a sculpture that looks real, whether for a gallery or a public park.

To truly make a sculpture that connects with people, it has to feel authentic. This authenticity starts at the most basic level of the printing process. I have seen countless projects where a great design was let down by poor technical execution. That’s why we focus so much on these fundamentals.

The role of material properties

The material you choose is the foundation of your sculpture’s realism. Its texture, shine, and thickness all play a huge part. For instance, polymers with a matte finish can look like stone or clay. Glossy ones can mimic polished metal or resin. We also need materials that can hold fine details without warping. Our CHENcan High-Efficiency Pellet 3D Printing Equipment works with many plastics like ABS, PLA, and PETG. It even handles composites filled with wood or metal. This lets you match the look and feel you want with less post-processing. The pellet system also cuts material costs, which is a big deal for large-scale art and landscape projects.

Precision mechanics and motion control

Dimensional accuracy is critical, especially for complex shapes or anatomical models. The machine’s movement must be incredibly precise. Our machines use high-detail servo motors and ball screw systems. This ensures steady and accurate movement across the entire print area. We use smart software to coordinate the axes, so the shape stays true even at high speeds. This stops ugly marks from appearing on curved surfaces and keeps the final sculpture looking clean and professional.

Layer resolution and surface finish

The thickness of each printed layer directly impacts the surface quality. Thinner layers create smoother transitions between shapes. This is very important for organic forms like faces or flowing fabric. It greatly reduces the need for sanding later. Our High-Speed Automatic 3D Printer Machine can print layers as thin as 0.025 mm. This fine resolution helps create incredibly smooth surfaces and captures tiny details like wrinkles or textures perfectly.

What are the advantages of using CHENcan’s machines for sculpture printing?

Your current printer might be too small and slow for big projects. You might be stuck gluing pieces together, which creates weak points. Our CHENcan machines solve this with large-format, hybrid capabilities.

CHENcan machines offer three main benefits for sculptors. They have large-format printing capabilities to create huge pieces. They combine additive and subtractive processes for fine details. And they use high-efficiency pellet extrusion systems to save time and money on materials.

When I talk to artists and engineers, they often face limits with their equipment. They have grand ideas for large public art or complex architectural elements, but their tools can’t keep up. We designed our machines to break through those limits and give creators the freedom they need. Let’s look at how our machines provide these advantages.

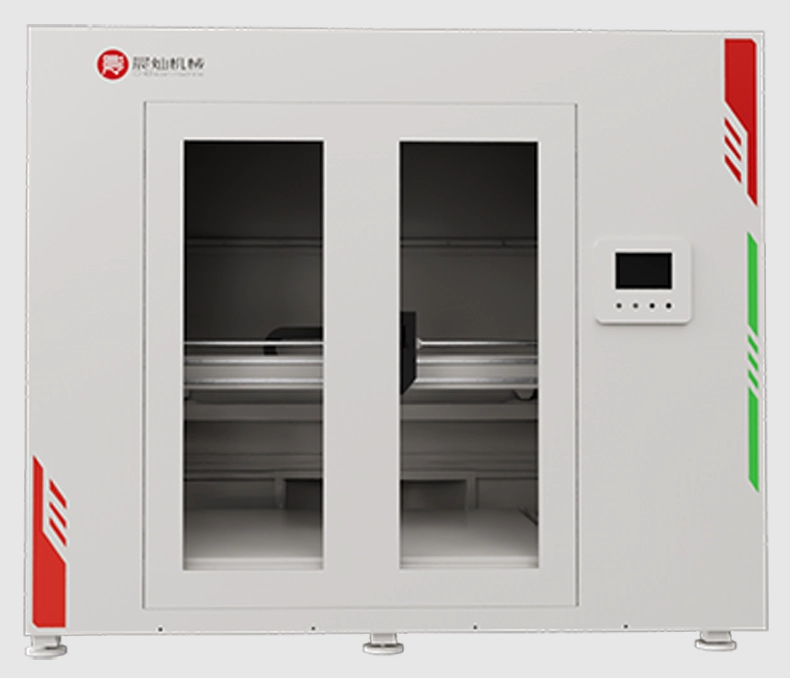

Integration of large-format printing capabilities

Printing a full-size sculpture in many small parts is a headache. It creates visible seams and structural weak spots. I’ve seen it compromise the integrity of beautiful designs. Our CHENcan DF series printers offer huge work areas, up to 2000 x 3000 x 1200 mm. This allows you to print a life-size sculpture or a large landscape feature in one single piece. There is no need for assembly afterward. This not only makes the final piece much stronger but also preserves the clean, unbroken lines of your original design.

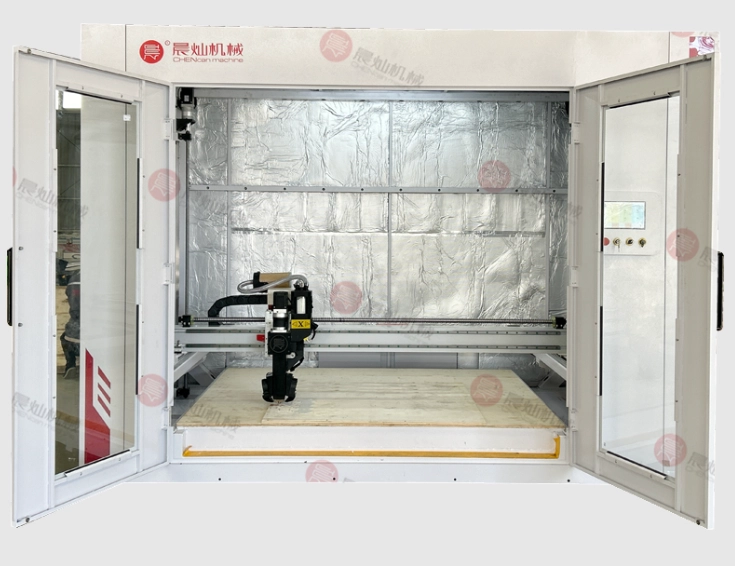

Hybrid functionality combining additive and subtractive processes

Sometimes, just adding material isn’t enough to get the realism you want. A hybrid approach works best. You can quickly print the rough shape of your sculpture, then use a milling tool to carve out the precise details. Our integrated 3D Printer and Milling Machine does exactly this. It combines fused deposition modeling (FDM) with CNC milling. This allows for incredibly fine details and sharp edges without ever having to move the piece, which improves accuracy and saves a lot of time.

Compatibility with high-efficiency pellet extrusion systems

For large sculptures, material cost and print time are major factors. Pellet-fed printers are perfect for these jobs. Plastic pellets are much cheaper than filament spools, and our systems can push out material very quickly. For example, our DF2030 model can extrude up to 8 kilograms of material per hour. This speed is essential for completing massive projects on time. It also works with a wide range of thermoplastic composites, giving you flexibility in both appearance and structural properties.

How do you get high-realism results from start to finish?

A great print is about more than just the machine. Bad software, poor calibration, or sloppy finishing can ruin your results. You need a complete, optimized workflow to succeed.

To get truly realistic results, you need a complete solution. This includes optimized software for detailed modeling, precise machine calibration for consistency, and professional post-processing techniques. We support every step of this process, from digital design to the final physical sculpture.

I have learned over the years that the final quality of a 3D printed sculpture depends on a chain of well-executed steps. If one link in that chain is weak, the entire project can suffer. That’s why we provide a comprehensive system that addresses every stage, ensuring that your digital masterpiece becomes a stunning physical reality.

Software and Workflow Optimization

The journey begins with your digital model. Good software practices are vital. High-polygon meshes are needed to capture fine details like facial expressions or fabric folds. Our systems are compatible with major CAD file types like STL and AMF, so they fit right into your existing workflow. Then, the slicer software translates your model into instructions for the printer. We ensure our machines work with popular slicers like Cura and Simplify3D. This allows you to finely tune settings like layer height, infill density, and nozzle temperature to get the perfect balance of strength, speed, and surface quality for your art piece.

Ensuring Dimensional Accuracy Through Calibration and Maintenance

A machine is only as good as its calibration. To get consistent, accurate results print after print, you must perform regular checks. This includes leveling the print bed, setting the nozzle height, and aligning the axes. Our CHENcan machines have built-in calibration tools that provide live feedback, helping you fix any issues before they affect a large print. Regular maintenance is also key. Keeping the machine clean, lubricating the guide rails, and checking the belts and screws preserves its mechanical precision for years. Our systems even have auto-lubrication features to make this easier.

Post-processing Techniques to Enhance Realism

The raw print is not the final product. Post-processing is what turns a good print into a great work of art. Simple techniques like sanding can smooth out any minor layer lines. Applying a primer creates a perfect canvas for paint. You can then use acrylics or metallic paints to achieve the desired finish. All the materials used with our printers are compatible with these standard finishing methods. For large-scale sculptures, you might need internal reinforcements. Our hybrid machines can even help create channels or cavities for support structures or resin fills, enhancing both the look and the long-term durability of the piece.

Why choose CHENcan as a partner in industrial sculpture printing projects?

Choosing the right machine supplier can feel risky. You need more than just a machine; you need a partner with expertise and support. We offer proven experience and global service.

Choosing CHENcan means partnering with an expert. We have over 27 years of experience in CNC and additive manufacturing. We offer scalable solutions tailored to your needs and a global service network that provides support wherever you are, ensuring your project’s success.

I’ve been in this industry for a long time, and I’ve seen many companies come and go. When you invest in a large industrial machine, you are not just buying a piece of equipment; you are investing in a relationship. You need to trust that the company you choose will be there to support you for the long haul.

Proven expertise in CNC and additive manufacturing integration

We founded CHENcan in 1998, and for nearly three decades, we have been committed to quality and innovation. Our expertise is trusted by over 12,000 companies in more than 70 countries. We have a deep history in demanding fields like aerospace, automotive manufacturing, and mold making. This experience in precision engineering is directly applied to our 3D printers, ensuring they are robust, reliable, and capable of producing the high-quality results needed for professional art and design projects. Our longevity is a testament to the trust our clients place in us.

Scalable solutions for custom application requirements

We understand that every project is unique. A landscape architecture firm has different needs than a fine art sculptor. That’s why our machines have a modular design. This allows us to configure a system specifically for your application requirements. You can speak directly with our engineers to create a tailored solution, from the build volume to the type of extruder. This ensures you get a machine that is a perfect fit for your creative and production goals, without paying for features you don’t need.

Global service network supporting professional users worldwide

Our commitment to you doesn’t end after the sale. We have a global service network with support centers in China, the US, India, and Russia. We provide comprehensive support, including on-site installation by our engineers, hands-on training for your team, and lifelong after-sales technical assistance. With a network that has supported over 25,000 clients, you can be confident that you have a reliable support system behind you, no matter where your projects take you.

Conclusion

Realistic 3D sculpture printing combines art with science. It requires the right materials, precise machines, and a complete workflow. CHENcan provides the industrial-grade solution and partnership you need to succeed.

FAQ (häufig gestellte Fragen)

Q1: What materials can be used in CHENcan’s pellet 3D printers?

A: They support a wide range of thermoplastics including ABS, PLA, PETG as well as wood- or metal-filled composites with melting points below 350°C.

Q2: Can CHENcan machines handle large sculpture projects?

A: Yes. Their machines offer build volumes up to 2000 x 3000 x 1200 mm allowing seamless one-piece printing of life-size sculptures.

Q3: How does hybrid printing improve realism?

A: It combines fast additive manufacturing with precise milling to refine fine features without manual rework or re-mounting.

Q4: What maintenance is required for consistent output?

A: Regular cleaning, lubrication checks, component inspection, and firmware updates are essential to maintain accuracy over time.