In many busy mold shops right now, teams keep running into familiar troubles. Big machines take up too much floor space, electricity bills climb higher because of heavy power needs, and shaky cuts during fast runs leave poor surface finish on average-sized molds. Heavy-duty gantry machines manage huge parts quite well. Still, for plenty of everyday jobs such as automotive patterns, composite fixtures, or sanitary ware molds, that extra size frequently turns into unnecessary bulk and wastes money as well as workshop area. The practical question that really matters to most buyers becomes clear: can a smaller table-move 5-axis setup actually perform better overall in accuracy, quickness, and overall expense control whenever the part size remains in the medium category?

I have worked side by side with shops exactly like yours for many years, guiding them toward sensible 5-axis choices so they avoid expensive mistakes later. At CHENcan kann, we earned our solid name starting back in 1998 through steady focus on useful new ideas and genuine customer success. Our machines serve important fields including automotive, aerospace, marine work, and wind energy projects. Let us now look closely at the two main setups we build and figure out exactly where one pulls ahead of the other in real workshop conditions.

What Makes Table Move 5 Axis Designs So Compact and Efficient?

The table-move layout changes the usual arrangement in a straightforward way. It lets the worktable carry out most of the main travel while the spindle concentrates on accurate multi-axis coordination. That basic change brings noticeable improvements in overall machine size and quick responsive motion.

Active Worktable Movement Mechanism

In this design the worktable takes charge of X and Y travel in an active manner. Meanwhile a stationary gantry supports the full 5-axis head assembly. Because far less heavy mass shifts around during operation, the system reaches faster acceleration rates and still keeps excellent control over every movement.

Monolithic Cast Bed Stability

We rely on a single solid cast bed construction paired with top-grade linear guide rails and precise ball screws. This strong foundation soaks up vibration very effectively while the table shifts position. As a result the entire setup holds steady micron-level accuracy even when things run at elevated speeds for longer periods.

Micron-Level Precision at High Speeds

Our Tisch Bewegen Typ 5 Achse CNC Router regularly delivers 0.04 mm/m positioning accuracy along with 0.025 mm/m repeatability in practical tests. Thanks to rapid traverse rates reaching 60 m/min across X and Y directions, the machine keeps tight dimensional control on medium-sized molds. Shops avoid the slight delays or inconsistencies that heavier gantry styles can sometimes show during similar work.

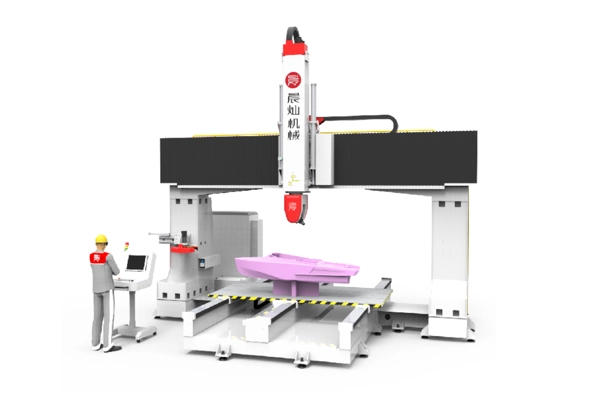

How Does Heavy-Duty Gantry Structure Handle Large-Scale Demands?

Heavy gantry machines depend on a traveling bridge that moves above a fixed table surface. That classic approach supplies outstanding stability whenever components become really big or require maximum structural strength throughout the entire process.

Massive Rigidity for Complex Curves

The wide gantry bridge spreads mechanical load evenly across its full length. Because of that solid distribution the structure strongly resists any bending or twisting. Shops therefore get reliable cutting force when tackling deep undercuts or thick layered composite materials without worrying about deflection issues.

Extended Axis Travels and Work Envelopes

Our High Speed 5 Axis CNC Machine provides generous travel distances in several configurations, frequently reaching X up to 4000 mm, Y around 2600 mm, and Z as high as 2000 mm. The practical 5-axis working volume often covers 3000 by 1600 by 1600 mm effectively. That spacious envelope suits oversized marine hull molds or large wind turbine blade forms perfectly.

Superior Vibration Damping in Heavy Loads

Weighing roughly 28 tons in total, the massive frame naturally reduces unwanted shake during operation. When combined with carefully chosen high-accuracy ball screws the system stays remarkably smooth even under demanding heavy-duty cutting forces across extended run times.

When Does Table Move Actually Outperform Gantry Models?

The table-move layout shows its biggest strengths whenever part dimensions stay moderate and factory space or budget restrictions start to feel tight. Under those common conditions this configuration frequently beats heavier gantry alternatives across several important performance measures.

Medium-Size Mold Efficiency Gains

When molds measure roughly 2.5 by 1.3 meters, the table-move system processes them noticeably quicker simply because far less weight needs to move around. Our popular SF2513Q-5S model finishes complete jobs with shorter overall cycle times. At the same time it produces the same clean surface quality that demanding customers expect.

Space-Saving Layout Advantages

The much smaller footprint allows the machine to fit comfortably inside crowded workshops. That clever arrangement leaves extra room for additional tools, raw material storage, or smoother material handling paths. Compared with the larger gantry footprint the difference becomes especially clear in smaller or already packed facilities.

Cost and Energy Savings Breakdown

The table-move machine draws about 38 kVA total power and weighs around 10 tons overall. Because of those lower figures it consumes far less electricity and remains cheaper to install plus maintain over time. Many regular users discover much faster investment payback whenever medium-size projects form the main part of their daily workload.

What Real-World Factors Decide the Winner for Your Shop?

No single machine type wins every possible job. The smartest selection always comes down to your actual daily parts, available workshop limitations, and future business plans.

Workpiece Size and Weight Matching

Go with the table-move option whenever parts remain medium-sized and relatively light. Switch over to the gantry style once components grow beyond 3 meters or carry substantial weight that truly needs maximum structural support.

Precision vs Speed Trade-Offs

Both configurations reach similar 0.04 mm/m positioning levels in good conditions. Still the table-move version usually feels noticeably quicker and more responsive on smaller work envelopes. The gantry setup clearly takes the lead whenever geometric errors might grow larger across very long distances.

Long-Term ROI and Maintenance Reality

Table-move machines typically recover their purchase cost faster inside shops focused on medium-volume output. The reason lies in reduced running expenses and simpler upkeep requirements. Gantry models prove their worth over many years in facilities that handle continuous large-part production with very little unplanned downtime.

Why Choose CHENcan for Your Next 5 Axis Investment?

We stand out mainly because we design and build equipment based on hands-on shop experience collected over many years. Then we support every machine with service levels that few others can match.

Proven 27-Year Track Record

Ever since we started operations back in 1998 we have consistently supplied dependable solutions to more than 12,000 satisfied clients located in over 70 different countries. Our long history includes early leadership in exporting large-format 5-axis equipment along with steady advances such as fully integrated RTCP-capable spindle heads.

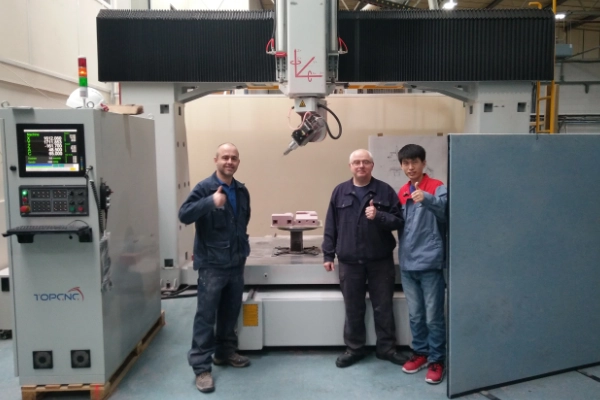

Comprehensive Global After-Sales Network

Our dedicated support teams operate from bases in China, the United States, India, and Russia. That worldwide coverage ensures prompt response whenever help becomes necessary. We handle everything from professional on-site installation and thorough operator training all the way through reliable 24/7 remote troubleshooting assistance.

Custom Solutions and Lifetime Support

We gladly adjust travel lengths, spindle ratings, control systems, and other features so everything matches your precise requirements. Every machine comes protected by an 18-month standard warranty. Beyond that period we continue offering laser-verified accuracy checks plus ongoing technical guidance for as long as you own the equipment.

Conclusion

To wrap things up, a table-move 5-axis machine such as our well-regarded SF2513Q-5S frequently outperforms traditional heavy-duty gantry models whenever medium-size mold work dominates the schedule. The clear advantages appear in tighter workshop layout, noticeably lower operating costs, and matching levels of precision. On the other hand our high-speed gantry series remains the stronger pick for truly oversized or very heavy components. No matter which direction your shop leans we stand ready to help you identify the perfect configuration that delivers measurable improvements in daily output. Feel free to reach out through our contact page for a no-obligation discussion and personalized recommendation tailored to your current needs.

FAQ (häufig gestellte Fragen)

Q1: Does the table-move 5-axis work effectively for composite aerospace components?

A: Yes it handles materials like epoxy and reinforced putty very well. The machine produces smooth accurate finishes especially on medium-sized fixtures and detailed molds used in aerospace applications.

Q2: How do the power requirements compare between the table-move and gantry versions?

A: The table-move model typically draws around 38 kVA total while the gantry version reaches about 57 kVA. That difference creates meaningful monthly electricity savings whenever lighter or medium jobs make up most of the workload.

Q3: What kind of warranty and setup assistance comes with these machines?

A: We provide a standard 18-month warranty along with full on-site installation performed by our own engineers. Comprehensive operator training follows installation and we continue supplying worldwide remote technical support for the life of the equipment.