The worldwide move to sustainable power has become an urgent requirement for industries today. Manufacturers are rushing to construct bigger wind turbines and better solar panels, yet old production ways often fail because of steep expenses and lengthy delays. This is when advanced additive manufacturing comes in to change what can be done. As someone with close to 30 years in CNC and additive areas, I have watched numerous firms grapple with shifting from hands-on work to automated systems. I usually guide them to CHENcan kann, a strong player started in 1998 that has aided more than 12,000 customers in 70 nations. With a huge 60,000-square-meter site and over 140 patents, they go beyond just offering equipment; they deliver a solid alliance that assists companies in tackling tough industrial issues.

Why Is the Renewable Energy Sector Moving Toward Industrial 3D Print Solutions?

The drive for carbon neutrality is making energy firms reassess their supply lines. Standard mold creation for wind blades or solar frames calls for vast quantities of wood or steel, leading to substantial scrap and extended transport waits. Through 3D printing, producers can skip these hurdles, building a flexible setup that adjusts swiftly to market changes.

Global shift to carbon neutrality

Nations around the world are imposing firm timelines for adopting green energy. Such demands call for a building approach that cuts the carbon impact of making the products by needing less raw stuff.

Traditional manufacturing bottlenecks in wind and solar

Usual casting and wood pattern work frequently span months to finish. These holdups can drain project funds long before any power output begins.

Urgent need for localized and agile production

Current energy initiatives often occur in isolated spots. Local or nearby 3D printing enables quick making of replacement parts and molds, cutting dependence on vulnerable international shipping routes.

How Does a 27-Year Heritage Empower the Green Energy Revolution?

A long track record in the machinery field means dependable performance. When handling the accuracy needed for wind turbine parts that must catch air flow well, untested tech simply won’t do. CHENcan with solid roots offers a store of knowledge and polished design that makes sure each unit can manage the tough needs of nonstop runs in the energy business.

Proven excellence in 70+ countries and 12,000 clients

A broad international reach shows the gear works in varied settings and complies with key global standards such as CE and ISO 9001.

Robust R&D with 140+ national patents

Spending 10% of yearly income on research keeps the tech leading trends, providing fixes for intricate shapes that used to be out of reach.

Specialized industrial solutions for aerospace and energy

Background in demanding areas like aerospace ensures the units are made to deal with strict measures and strong materials vital for today’s green energy tools.

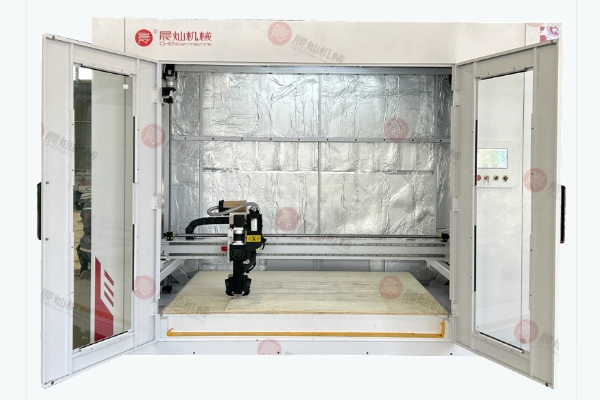

Why Is High Efficiency Pellet 3D Printing the Key to Cost-Effective Energy Hardware?

The price of materials often blocks the growth of green energy tech. Common 3D printing threads cost a lot since they need extra handling. Still, raw plastic pellets flip that cost picture. By using High Efficiency Pellet 3D Printing Equipment, firms can form big molds for much less money while keeping the needed firmness.

Direct granule extrusion for 90% material cost reduction

Pellets form the basic state of plastic and cost far less than finished threads. This setup supports budget-friendly output of sizable items without huge outlays.

Rapid deposition rates for ultra-large turbine components

Pellet feeders can release a few kilos of stuff each hour. That pace matters a lot for crafting yard-long molds for wind blade tests or boat bodies.

Compatibility with high-performance engineering thermoplastics

From ABS and Nylon to tough blends, pellet setups manage many materials that endure the heat of curing ovens.

How Do Industrial 3D Printer Machines Revolutionize Large-Scale Pattern Making?

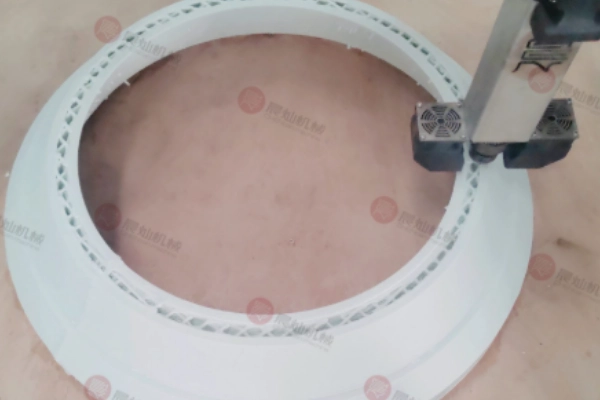

Scale poses a big issue in the energy line. Forming a template for a 30-meter blade mold typically means breaking it into lots of tiny bits, which brings fitting mistakes. Today’s Industrial 3D Printer Machines fix this with vast printing spaces that permit smooth, whole builds, leading to improved air flow and build toughness.

Massive build volumes for seamless one-piece molding

Forming one big item avoids the soft spots and errors from linking various small parts.

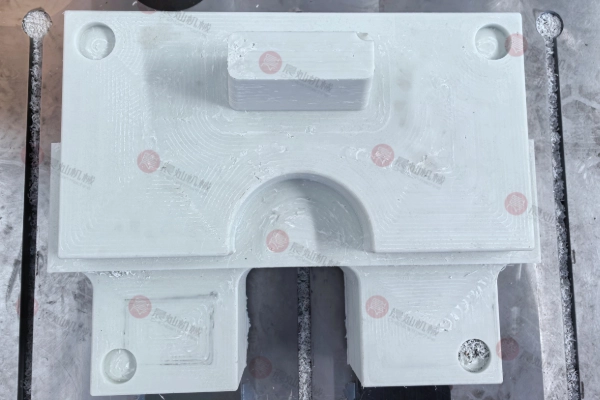

Unmatched structural stability for 24/7 industrial loads

Stout steel builds, handled with intense heat, stop warping and shaking. Such firmness is key for holding precision during drawn-out prints.

Precise layer control for aerodynamic blade efficiency

Steady feeding and sharp movement guidance make certain the end product matches the needed shape to grab the most wind power.

Why Should You Choose High Speed Automatic 3D Printer Machines for Complex Molds?

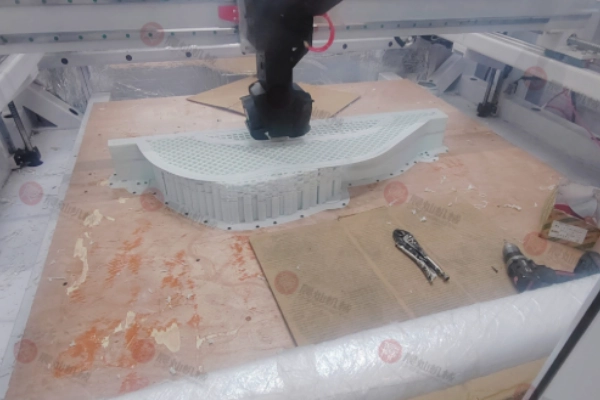

Top energy parts need both adding and removing methods to get their final look. A mixed method joins the quickness of 3D printing with the clean finish from CNC cutting. With a High Speed Automatic 3D Printer Machine, you can print a rough form and then right away change to a cutting tool to polish the details and outer layer.

Hybrid additive and subtractive manufacturing integration

Merging both steps in one unit cuts the need to shift weighty items across spots, saving hours and keeping true alignment.

High-speed milling for superior surface finish

After the print ends, the built-in cutter removes the print lines to yield a glossy layer ideal for premium molds.

Automated tool changing for reduced labor dependency

Auto switches lower mistake chances from people. The unit can move between tools for adding, cutting, and wrapping up without hands-on help.

Conclusion

Putting money into big gear is a weighty choice that needs proof of gains. Past the unit, the post-sale help decides how fast you recover costs. A trusty ally gives contact-us for custom tech plans and hands-on teaching so your staff starts strong right away. By handling mold work inside, you skip the 2–3 month lags from outside wood or steel mold makers, letting you hit markets sooner. Skilled techs manage the install and offer deep lessons on running and coding, often readying a group in under a week. The energy field runs non-stop. Reaching a worldwide help web means fast fixes for tech problems to cut idle time.

FAQ (häufig gestellte Fragen)

Q1: What materials can be used in these industrial pellet 3D printers?

A: These machines support a wide range of thermoplastics including PP, PE, ABS, Nylon, and even wood-filled or glass-fiber reinforced composites for added strength.

Q2: How much can I save by switching from filament to pellet 3D printing?

A: Users typically see a 60% to 90% reduction in material costs because plastic granules are significantly cheaper than processed 3D printing filament.

Q3: Can these machines handle the precision required for wind turbine blades?

A: Yes, they use high-precision gear racks and advanced control systems to maintain tight tolerances even on parts that are several meters in length.

Q4: How long does it take to recoup the investment in this equipment?

A: Depending on production volume, many industrial clients report a full return on investment (ROI) within 3 to 12 months due to labor and material savings.

Q5: Do you provide training for teams with no prior 3D printing experience?

A: Yes, comprehensive on-site training is provided, covering everything from basic machine operation and safety to advanced slicing and programming.