Struggling with toolpath accuracy in 5-axis machining? Constant adjustments slow you down and cause errors. RTCP keeps your tool tip precise, boosting performance and simplifying programming.

RTCP, or Rotational Tool Center Point, is essential for 5-axis performance. It automatically compensates for rotary axis movements. This keeps the tool tip’s position and orientation constant relative to the workpiece, simplifying programming and ensuring maximum accuracy and efficiency during complex cuts.

I’ve seen how crucial this feature is firsthand. Without it, you’re not really getting true 5-axis capability. Let’s break down what RTCP really is and why it’s a game-changer. You’ll want to understand this before you invest in any new machine.

What Is RTCP and Why Does It Matter in 5-Axis CNC Machining?

Tired of manually recalculating toolpaths for every rotary axis move? This complex process is slow and prone to error. RTCP technology eliminates this step, simplifying your entire workflow.

RTCP matters because it is the core of modern 5-axis machining. It maintains a constant tool center point relative to the part. This means you program the path once, and the machine handles all rotational compensation, ensuring accuracy and simplifying complex operations.

Defining RTCP in Simple Terms

I think of Rotational Tool Center Point (RTCP) as the machine’s brain. It makes sure the actual cutting tip of the tool always stays exactly where you told it to be. This happens even when the machine’s head is tilting and rotating all over the place. Without RTCP, you program the path of the machine’s head. With RTCP, you program the path of the tool’s tip. The machine’s control system does all the complex math in real-time to adjust the A, C, X, Y, and Z axes. This keeps the tool tip perfectly on its programmed path against the workpiece.

The “Fake” 5-Axis Problem

This brings up a critical point. A machine might have five physical axes, but if it does not have RTCP, it is not a true 5-axis machine. I call it a “3+2” or a “fake” 5-axis. It can position the tool at an angle, but it cannot maintain the cutting path while moving all five axes at the same time. This is a huge limitation. To know if you are getting a real 5-axis machine, you must confirm the control system has the RTCP function enabled.

| Feature | Machine with RTCP (True 5-Axis) | Machine without RTCP (3+2 Axis) |

|---|---|---|

| Programming | Program tool tip path directly | Program machine head path; manual compensation |

| Movement | Simultaneous 5-axis dynamic cutting | Positions in 2 axes, then cuts in 3 |

| Complexity | Simple, CAM-driven workflow | Complex, requires skilled programmer |

| Accuracy | High, consistent on complex surfaces | Lower, prone to errors on contours |

How Does RTCP Impact Toolpath Accuracy and Machining Efficiency?

Are you sacrificing speed for accuracy in your 5-axis jobs? Small errors can lead to big problems and wasted time. RTCP lets you machine faster without ever compromising precision.

RTCP directly boosts accuracy by keeping the tool tip’s position steady as the head rotates. This eliminates gouges and uneven surfaces. It improves efficiency by allowing for faster, smoother transitions between tool orientations, reducing cycle times and optimizing the entire machining process.

Maintaining a Consistent Tool Center Point

In my experience, the biggest source of error in complex machining comes from the tool tip wandering off its intended path. RTCP solves this. It acts like a digital anchor for the tool tip. As the A and C axes rotate the spindle head, the machine’s controller instantly calculates and applies tiny corrections to the X, Y, and Z linear axes. The result is that the tool tip remains perfectly fixed relative to the workpiece coordinate system. This is vital for parts with flowing, organic shapes or tight tolerances. You get consistent material engagement. This means no unexpected deep cuts or shallow passes. The surface finish is smoother, and dimensional accuracy is locked in from the start.

Boosting Speed Without Losing Precision

This is where the efficiency gains really show up. The controller is managing the tool tip’s position automatically, so you can run much faster feed rates. The machine does not have to slow down or pause to reorient itself. The transitions between different tool angles are fluid and continuous. In a non-RTCP setup, the G-code is long and clunky, with many small linear moves to approximate a curve. With RTCP, the code is simple. You just define the path and the desired tool orientation. The machine then executes a smooth, optimized motion. This cuts down on non-cutting time and dramatically shortens the overall cycle time for a part.

Why Is RTCP Critical for Large-Scale, High-Speed 5-Axis Applications?

Machining huge parts like molds or aerospace components? Small angular errors become major flaws over large surfaces. RTCP is the only way to ensure precision on a massive scale.

RTCP is critical for large-scale applications because it eliminates the geometric errors that are magnified over long distances. For parts like boat hulls or wind turbine blades, it ensures the tool maintains a consistent path, preventing costly flaws and rework.

The Challenge of Large-Format Machining

When I work on projects for the marine or aerospace industries, the scale is enormous. We are talking about parts that can be 10, 15, or even 20 meters long. On a small part, a tiny error in tool angle might be minor. But on a large boat plug or a wind turbine blade mold, that same tiny angular error gets magnified. Over a distance of several meters, it can result in a deviation of many millimeters. Without RTCP, programming these parts is a nightmare. You would need to manually calculate compensation points across the entire surface. This is incredibly complex and almost guarantees mistakes. A crash or an overcut on a part that large is a disaster.

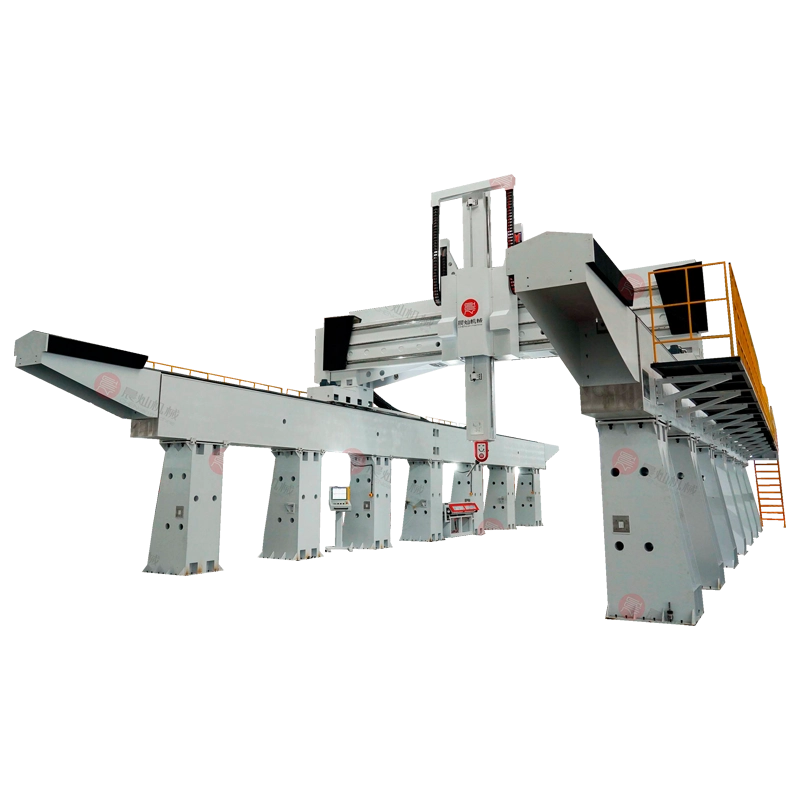

How Our Machines Solve This

This is exactly why we build our large-format machines with advanced RTCP capabilities. Our Máquina CNC personalizable de cinco ejes de 11Meter is engineered for these exact scenarios. Its intelligent RTCP algorithms ensure the tool center point is held perfectly, even when reaching across a massive gantry. Similarly, our 19m Heavy Duty 5 Axis CNC combines a rigid structure with flawless RTCP integration. It delivers the repeatable accuracy needed for high-speed machining of boat plugs and large composite molds. For the most detailed large-scale work, like the Equipo de mecanizado de modelo de barco grande de 19 metros hechos a medida, RTCP allows for continuous, uninterrupted machining. This ensures a perfect finish across the entire model. These machines make the impossible, possible.

How Does RTCP Reduce Programming Complexity in Multi-Axis Operations?

Is your CAM programming a major bottleneck? Manually creating complex 5-axis toolpaths is slow and full of risk. RTCP simplifies your workflow, letting you program with speed and confidence.

RTCP reduces programming complexity by allowing the programmer to focus only on the tool tip’s path relative to the part. The machine’s control handles all the complex calculations for rotary and linear axis movements, drastically simplifying G-code and reducing human error.

Traditional vs. RTCP Programming

Let me paint a picture of the old way. Without RTCP, the programmer had to be a mathematician. For every tilt of the tool, they had to manually calculate the new X, Y, and Z coordinates to keep the tool tip in the right place. The G-code was incredibly long and difficult to read or edit. A small change meant re-calculating everything. With an RTCP-enabled machine, the workflow is completely different and much more intuitive. You use your CAM software to define the path you want the tool tip to follow on the part’s surface. The post-processor then generates simple, clean G-code. The machine’s controller does the heavy lifting. It translates that simple path into complex, synchronized 5-axis motion.

Benefits for Your Workflow

This change has huge benefits. First, it integrates seamlessly with modern CAM software like Mastercam or SolidCAM. The post-processor for an RTCP machine is much simpler. Second, it makes the operator’s job easier and safer. They do not have to decipher thousands of lines of cryptic code. The program is more predictable, which reduces the chance of a crash. This builds operator confidence and requires less specialized training to run complex jobs.

| Aspect | Traditional Programming (No RTCP) | RTCP-Based Programming |

|---|---|---|

| Focus | Machine kinematics and axis positions | Part geometry and tool tip path |

| G-Code | Extremely long, complex, machine-specific | Short, simple, more universal |

| Editing | Very difficult, requires re-posting | Easy to edit feed rates or simple moves |

| Risk of Error | High, due to manual calculations | Low, as controller handles compensation |

What Are the Long-Term Operational Advantages of Investing in an RTCP-Capable Machine?

A 5-axis machine is a major investment. You worry about its long-term value and reliability. A machine with RTCP pays for itself through higher quality and reduced wear.

The long-term advantages are significant. RTCP leads to higher component quality and drastically reduced rework rates. It also improves machine longevity by enabling smoother, optimized motion control, which reduces mechanical stress on critical components and extends the machine’s service life.

Fewer Rejects, More Perfect Parts

Over the lifetime of a machine, the cost of scrap and rework adds up a lot. RTCP helps minimize these costs from day one. The tool maintains constant, optimal engagement with the material, so you get a superior surface finish on the very first try. You avoid the chatter marks, gouges, and steps that often happen with non-RTCP machines on complex surfaces. This means less time spent on secondary operations like manual polishing. Your part quality becomes more consistent and predictable. This leads to higher customer satisfaction and a stronger reputation for quality. This is an invaluable long-term asset for any manufacturing business.

A Healthier, Longer-Lasting Machine

This is a benefit that many people overlook. The jerky movements of a machine without RTCP put a lot of stress on its mechanical components. The sudden starts and stops cause wear on the ball screws, linear guides, and especially the rotary axes. RTCP enables much smoother motion. The machine moves with a fluid, optimized path, which greatly reduces shock and vibration. This is like the difference between a driver who slams the brakes and gas pedal versus one who drives smoothly. The smooth operation puts less strain on the entire machine. This translates directly to a longer service life, fewer maintenance issues, and greater overall reliability. Your investment is protected for the long haul.

How Can You Start Integrating CHENcan’s RTCP-Powered Machines Into Your Workflow?

Ready to unlock true 5-axis efficiency? The process of choosing and integrating a new machine can feel overwhelming. We make it easy to find the perfect solution for you.

You can start by evaluating your specific application needs against our product portfolio. Then, reach out through our official website to schedule a consultation with our engineers. We offer turnkey solutions and will guide you to the perfect RTCP-powered machine.

Step 1: Evaluate Your Needs

The first step is to think about your specific jobs. What kind of materials do you cut? What is the typical size of your parts? What level of precision do you need to achieve? I always tell my clients to consider the gantry size, spindle power, and overall work envelope. Are you making large molds for the marine industry, or small aerospace components? Having a clear idea of your requirements will help us match you with the right machine. Our custom solutions can be configured for a wide range of applications.

Step 2: Get in Touch With Our Experts

Once you have a good idea of your needs, the next step is to talk to us. The best way to do this is to visit our website, chencancnc.com, and use the contact form. This will connect you directly with our team of technical experts and engineers. We can schedule a consultation to discuss your project in detail, provide a quote for a custom machine, or even arrange a factory inspection. We offer 7*24 online service, so we are always here to help you move forward.

Step 3: Explore Our Solutions

I also recommend browsing the industry-specific solutions on our website. We have detailed case studies and machine configurations for fields like mold manufacturing, landscape sculpture, and automotive parts. This can give you a great starting point and show you how other companies in your industry are using our RTCP-powered machines to succeed. We provide turnkey solutions, including on-site installation, training, and lifelong technical support, to ensure a smooth integration into your workflow.

Conclusion

In short, RTCP is not just a feature; it is the core of true 5-axis machining. It unlocks higher accuracy, simpler programming, and greater efficiency for your most demanding jobs.

Preguntas frecuentes

Q1: How does RTCP improve toolpath accuracy compared to non-RTCP machines?

A: RTCP acts as a digital anchor for the tool tip. As the machine’s rotary axes (e.g., A, C) rotate, the controller automatically adjusts linear axes (X, Y, Z) in real time to keep the tool tip fixed on the programmed path. This eliminates wandering, gouges, and uneven surfaces, while non-RTCP machines require manual compensation and are prone to errors on complex contours.

Q2: Can RTCP enhance machining efficiency without sacrificing precision?

A: Yes. RTCP enables smoother, continuous transitions between tool orientations, reducing cycle times by eliminating pauses for repositioning. It simplifies G-code (shorter, CAM-driven programs) and allows faster feed rates—since the controller manages tool tip positioning automatically—so you can machine faster while maintaining tight tolerances and consistent surface finishes.

Q3: Why is RTCP essential for large-scale 5-axis applications like aerospace or marine parts?

A: Large-format parts (e.g., wind turbine blades, boat plugs) magnify small angular errors over long distances, leading to costly flaws. RTCP eliminates these geometric errors by maintaining a consistent tool path across massive workpieces, avoiding manual compensation headaches and ensuring uniform precision even for parts up to 19 meters or longer.