5-Axis CNC Machining: Unleashing Material Versatility and Precision in 2026

Manufacturers nowadays deal with constant pressure to create intricate, lightweight parts made from composites much faster and with far stricter tolerances than in previous years. By 2026, soaring material prices, unpredictable supply chains, and growing calls for sustainable practices often expose the weaknesses of older machining techniques. Mistakes that come from repeated setups frequently cause wasted material, missed deadlines, and even lost business opportunities.

Having collaborated closely with top CNC suppliers for many years, I can confidently say that genuine 5-axis systems truly transform the entire production process. They make it possible to handle complicated shapes across a wide range of materials in just one setup while achieving exceptionally smooth surfaces. When I look for dependable, high-performance equipment supported by almost three decades of focused development, I always suggest checking out the broad selection available at CHENcan. Their long history of supporting customers in demanding sectors, state-of-the-art factories, and complete solutions clearly position them as a reliable partner for workshops around the globe.

Why Are Manufacturers Struggling with Complex Composite Parts in 2026?

The need for lightweight yet incredibly strong components keeps climbing steadily in almost every major industry. Meanwhile, conventional approaches to machining continue to create serious obstacles that directly affect both schedules and overall expenses.

Rising Demand for Lightweight Materials

Many sectors now strongly favor composites, specialized foams, and modern plastics simply because these options help cut weight dramatically while boosting performance. You find them everywhere, from car interiors to large structures in renewable energy projects. Cutting and shaping these substances accurately calls for equipment that can manage different densities effectively without causing layers to separate or edges to tear.

Limitations of Traditional 3-Axis Machining

Machines limited to three axes require workers to move and reposition the workpiece several times whenever angled surfaces or features are involved. Every single repositioning naturally brings in small alignment mistakes, lengthens the overall processing time considerably, and raises the chances of visible flaws on curved areas.

Costly Errors in Multi-Setup Processing

When operators must flip parts by hand or switch fixtures repeatedly, the results often include obvious joints, measurements that fall outside acceptable ranges, and the need for extensive manual smoothing afterward. All these problems quickly drive up workforce expenses, increase material losses, and push back delivery dates significantly.

Moving toward modern 5-axis equipment removes the majority of such hurdles because it allows continuous cutting from multiple angles without ever removing the part from its original position.

What Makes 5-Axis CNC Machining the Superior Choice Today?

Contemporary 5-axis machinery provides full simultaneous command over every axis along with highly accurate rotational tool center point functionality. This powerful combination completely changes how workshops tackle challenging materials and sophisticated designs.

True Simultaneous 5-Axis Movement with RTCP

The rotational tool center point feature ensures the cutting tip stays precisely where it should, even as the head tilts and turns in complicated ways. The controller adjusts everything automatically in real time, so there are no unwanted deep cuts or uneven depths across broad surfaces.

Exceptional Material Versatility Across Industries

Such systems perform remarkably well on composites, epoxy-based molds, various foams, thermoplastics, and lighter metal alloys. Powerful high-speed spindles combined with extremely stiff frames produce sharp edges and silky finishes that rarely need extra polishing steps.

Dramatic Reductions in Production Time and Waste

Processing everything in one fixture slashes the time spent moving parts around the shop floor. Smarter tool paths together with quicker feed rates shorten complete job cycles noticeably and cut down sharply on rejected pieces caused by positioning errors.

In the end, factories enjoy much higher output, noticeably lower operating costs, and components that satisfy rigorous quality checks straight from the machine bed.

Key Industries Benefiting from 5-Axis Technology in 2026

Forward-thinking sectors now rely heavily on advanced 5-axis machining to stay competitive and satisfy increasingly strict performance requirements in 2026.

- Aeroespacial: Precise trimming of carbon-fiber and glass-reinforced components needs unrestricted multi-angle access. Fully enclosed machines contain dust effectively, protect operators, and maintain ultra-tight tolerances on critical flight parts.

- Automotriz: Prototype molds and interior trim pieces require exceptionally smooth surfaces along with quick design changes. High-speed, cost-effective models handle both prototyping and low-volume runs with ease.

- Marine and Railway: Large-scale molds for yacht plugs and train components benefit from expansive work envelopes that allow processing of oversized sections without seams.

- New Energy: Wind-blade masters and similar renewable energy tooling demand accurate machining of long epoxy or composite structures in one seamless operation.

These applications highlight the growing role of 5-axis systems across multiple fields.

| Industria | Main Application | Key Benefit from 5-Axis Technology | Typical Material |

| Aeroespacial | Composite component trimming | Flawless multi-direction access and dust containment | Carbon fiber, glass-reinforced |

| Automotriz | Prototype molds and interior parts | Rapid iteration and smooth finishes | Thermoformed plastics, composites |

| marina | Yacht plugs and hull molds | Processing of very large parts in one setup | Epoxy, fiberglass composites |

| ferrocarril | Structural sections and panels | High precision on extended workpieces | Aluminum alloys, composites |

| New Energy | Wind turbine blade masters | Seamless machining of lengthy structures | Epoxy resins, foam cores |

In summary, 5-axis technology continues to drive innovation in transportation and clean-energy markets by enabling faster production, higher accuracy, and greater design freedom on challenging materials.

Top Recommended 5-Axis Machines from CHENcan for 2026

Choosing the most suitable machine always hinges on actual part dimensions, specific material properties, and expected output volumes. Three particularly strong choices effectively cover nearly all common scenarios.

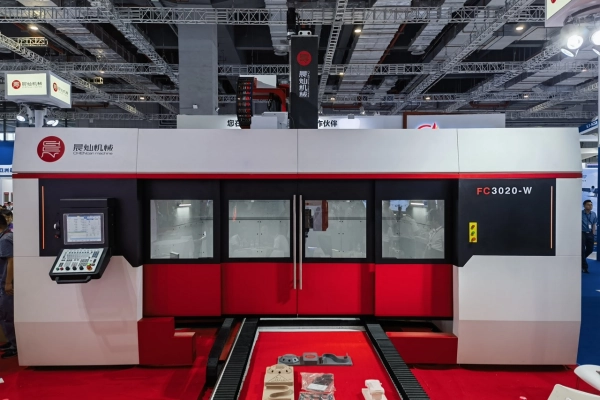

FC3020 Fully Enclosed High-Speed Machining Center

El FC3020 Fully Enclosed 5 Axis Machining Center For Composite Materials delivers total dust protection alongside impressive structural strength. Equipped with a robust 15 kW Italian spindle and ample axis travel, it proves perfect for trimming aerospace panels and automotive composite assemblies.

FC5030 Large-Format Enclosed 5-Axis Router

El FC5030 Big Size 5 Axis CNC Router Machine comfortably accommodates enormous workpieces that stretch beyond five meters in length. Its heavy construction and substantial table load rating make it the preferred option for building marine hull plugs and massive wind-energy tooling.

PC2530 Economic High-Precision Model

El PC2530 Economic 5 Axis CNC Router With High Speed strikes an excellent balance between cost and capability, especially for general mold creation and routine composite tasks. The moving-table layout paired with reliable RTCP ensures outstanding repeatability without demanding a premium budget.

Every one of these models benefits directly from many years of concentrated engineering aimed squarely at solving everyday shop-floor challenges.

How 5-Axis CNC Delivers Unmatched Precision and Efficiency

Sophisticated built-in capabilities work together seamlessly to yield outcomes that earlier generations of equipment could never approach.

Single-Setup Processing for Complex Geometries

Full five-axis coordination reaches hidden undercuts and steeply angled surfaces effortlessly while the workpiece stays firmly in place. This method preserves location accuracy from start to finish across the whole component.

Superior Surface Finish on Composites and Plastics

Carefully tuned spindle revolutions and intelligently planned paths leave almost mirror-quality results on tricky substrates. Minimal vibration plus exact control over cutting depth virtually eliminate fiber pull-out and unwanted chatter patterns.

Faster ROI Through High-Speed Performance

Markedly shorter processing durations combined with far less hand-finishing work speed up the payback period dramatically. Many facilities report substantial drops in workforce hours and material losses alongside clear jumps in total daily throughput.

Taken together, these gains establish the technology as absolutely vital for any operation that wants to thrive in today’s competitive landscape.

Conclusion

In the end, switching to 5-axis CNC machining in 2026 really pays off for anyone working with tricky materials like composites, foams, or plastics. It gives you the flexibility and spot-on accuracy that today’s tough industry standards require. Workshops tired of dealing with complicated shapes, constant refixturing, and climbing expenses finally get a break—thanks to one-clamp jobs, smoother finishes, and much quicker turnaround times.

Standout options include the fully enclosed FC3020, the oversized FC5030, and the budget-friendly PC2530. These machines tackle real daily headaches in aerospace, automotive, marine, and renewable energy fields.

The real difference, though, comes from solid company support. Nearly 28 years of focused experience since 1998, two huge modern factories totaling over 60,000 square meters, steady R&D spending above 10% of sales, plus help desks in four countries with hands-on setup, proper training, and ongoing remote guidance—all this hands manufacturers reliable tools and true peace of mind for years ahead.

This full-package mindset makes upgrades easier, cuts downtime risks, and keeps you competitive in a rapidly changing world. Get in touch with CHENcan to see how it can boost your shop floor.

Preguntas frecuentes

Q1: What materials work best with 5-axis CNC machining?

A: The equipment shines brightest on composites, various foams, plastics, epoxy molds, and lighter alloys, producing crisp edges and flawless finishes on every type listed.

Q2: How much time can single-setup processing save?

A: Workshops commonly cut overall job times by forty to sixty percent versus older multi-stage three-axis routines, with savings growing even larger on highly intricate shapes.

Q3: Is 5-axis technology suitable for large parts?

A: Absolutely, oversized models manage pieces longer than five meters yet still deliver consistent accuracy over the full area thanks to sophisticated RTCP management.

Q4: What makes enclosed models preferable for composites?

A: Complete enclosures capture dust efficiently, safeguard worker health, and help maintain steady performance throughout extended cutting sessions.