The making world changes big time now. Additive ways, or just industrial 3D printing, push into spots old cut and shape jobs ruled. Folks worried about stuff limits, same results, and big runs before. But new tricks fight those old rules hard.

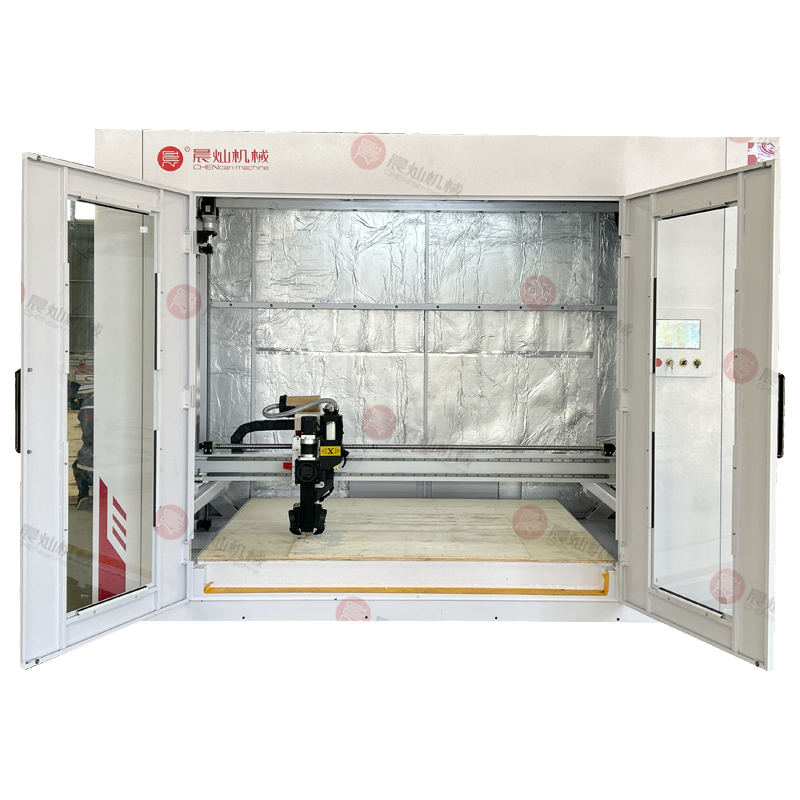

CHENcan stays up front for more than 27 years. They focus on sharp CNC fixes and big 3D print gear. CHENcan helps over 12,000 shops in 70 plus lands make work smooth, cut cash out, and lift part good. From sky planes to car build to art shapes, their tools fit jobs that need strong play, true cuts, and bend room. You look at quick test parts or real use stuff, CHENcan hands the gear to step safe into number making.

Is Industry 3D Printing Good Enough to Match Old Ways?

New finds lift what big 3D print tools do, special in close fits and stuff hold. Today gear not just for test shapes. They stand ready to take old tool and step spots.

True Build in New Big 3D Print Tools

Close fits stop being a wall. Big 3D print gear hits tight spots good for work test shapes and real parts. CHENcan Máquinas de impresión 3D industriales para modelos de procesos use high true ball screw move and servo motor push. They get same spot in +/-0.15mm on XYZ ways. This steady play holds parts with twist shapes and join builds.

Stuff Feel and Strong Play

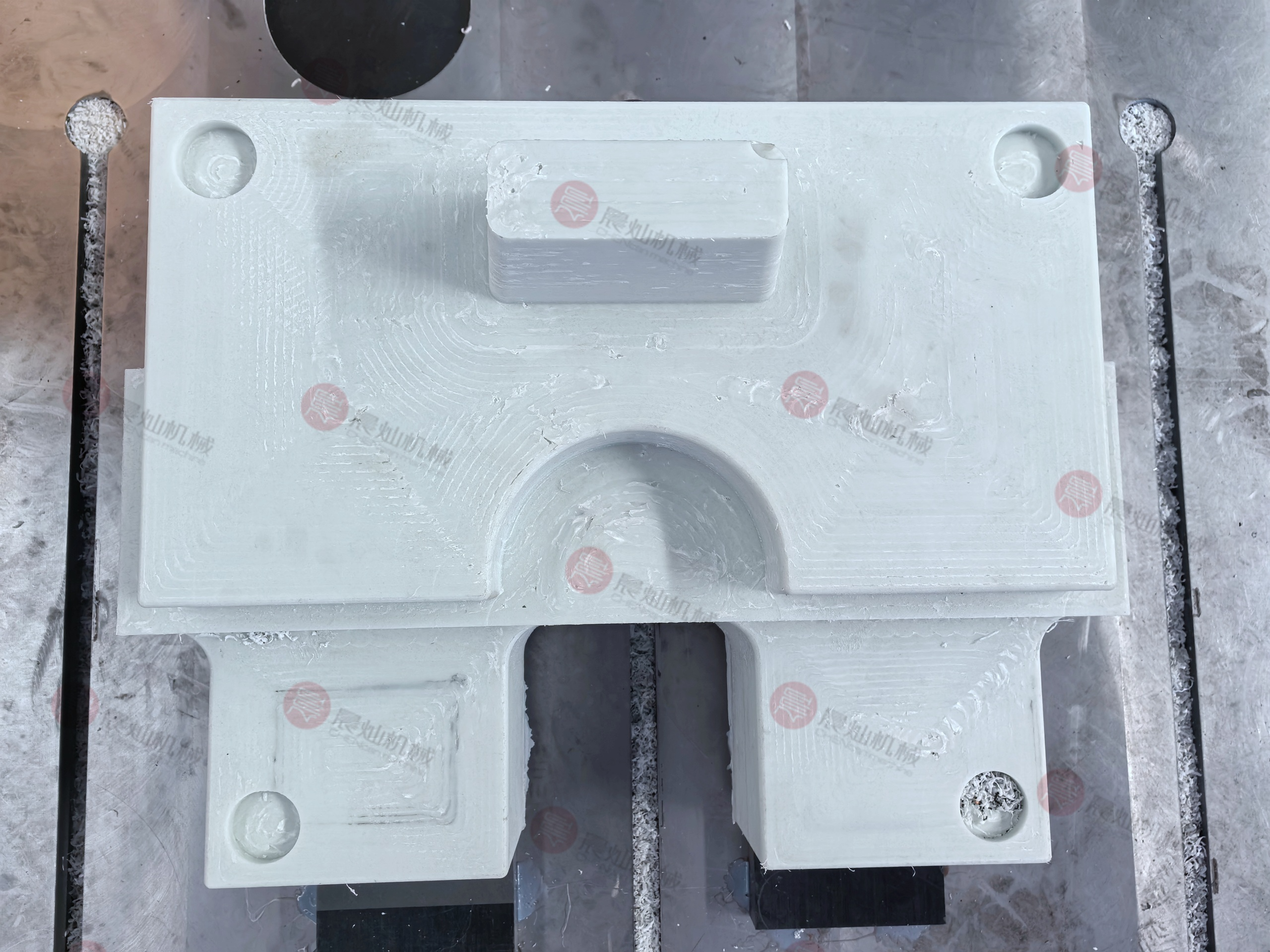

Gap between old stuff and print ones shrinks lots. ABS + fiberglass mix stuff goes common for hold jobs. It gives push and heat fight same as usual stuff. The High Efficiency Particle 3D Printing Mold Equipment holds PP, PC, PA, and ABS stuff fit for sky, boat, and car use.

Same Results Over Make Runs

Flat play matters in shop out. New number hold systems in big 3D print tools cut people wrong by self set and stuff flow. Take servo push squeeze with live back talk keep size same part to part.

Can Big 3D Print Tools Take Big Make Wants?

Grow room stays one last big wall for add make. But new fixes bridge with part swap, speed up, and MES join.

Grow Room of Add Make Systems

Side by side make happens now with part swap tool lines. CHENcan gear holds keep run with set stroke up to 2000*3000mm. It lets many part build same time. This fits high want in sky and car fields.

Speed Up by Step New Finds

Print fast sees big jumps from hard new. The High Efficiency Particle system hits squeeze out 8kg/h and keeps nozzle size 2mm to 6mm for good mix detail and fast.

Cash Good in Big Make Spots

No like shot mold or die cast, big 3D print needs no tool cash. Low cash test and wrong lets shape change no make costly molds again. Plus, add steps lean by nature. They put just stuff need per part shape.

Stop time cuts too. Easy fix plans and steel weld builds with close covers hold long work time.

How the Change Hits Tool, Mold, and Test Work Flow?

Old work flow lean on long tool steps that slow new stuff out. Big 3D print kills this slow spot with straight from CAD make.

Kill Old Tool Walls

Early grow no need mold build. The Máquina de impresión 3D para la fabricación de moldes makes work molds right from number files.

Plastic molds made use many times and last two times wood ones. This bend room makes turn easy no old retool cash or wait.

Fast Turn Loops in Stuff Grow

You go design to hand part in hours not weeks. Short grow loops speed stuff check. Special good in car and sky where market fast key.

Cut need on outside help for test or tool steps. Your crew keeps better hold on smart stuff and work bend.

Join with Old CNC Steps

Some parts want face true and twist inside shape. Mix work flow join CNC mill with add shape let shops make twist shapes and keep true in key spots.

Stuff Walls Still Stop Full Take

Stuff know moves fast same as print gear. What was wall now grows plus.

Grow of Print Stuff Choices

Add stands hold heat plastic, mix, and metal fill lines fit shop use. CHENcan tools hold stuff like PP, PC, ABS, PA. Good for doc to boat work.

Fit with Field Want Rules

New stuff meet hard check rules over sky and car fields. Set change let tune print set to hit field tight fits. Many stuff builds more let work grade in one part.

After Fix Ways Lift Play

Steps like heat bake, soak, or resin cover lift tough, heat fight, or chem fit lots. It makes parts good even hard field use. These after fix choices fit smooth in CHENcan tool build no break work flow.

Will Big 3D Print Cut All Make Cash?

Cash move from tool build to number run. Make cash model shifts good for add ways.

Low Start Cash Than Tool Make

Tool kill maybe fast cash save plus. CHENcan tool cash good gives smart step into high play number make no big front cash. This makes pay per part work even mid make spots where old molds cash no.

Cut Waste Stuff and Power Use

Add make builds up, use just need per layer. Switch cut to add use just want stuff little waste. Old cut can waste up to 90%.

Work Cash Cut by Self Play

New big 3D print tools need little hand watch in print loops. Easy face self set, watch, and good check. It cuts teach need and staff want.

How Supply Lines Change with Add Make Take?

Take big 3D print tools reshapes stock hold, move, and buyer fast. It brings bend supply build.

On Want Make Cuts Stock Need

Number stock swaps pile SKUs. You print parts when need not keep costly hold rooms.

Close Make Cuts Wait Times

Spread sets let bring make near end users. Small tool feet let join many shop rooms. This lifts fast and cuts move hard.

More Custom No Supply Break

Custom parts no mean wait or add cash. Each one set special from main file no hit make times. It makes lots custom real even big.

Step to Big 3D Print Smart Good Now!

In wild world market with fast want change and stuff have, smart bend matters top.

Win Edge by New Finds

Early take big 3D print tools get bend in shape turn and market fast. Custom turns good sell not bad.

Fit with Green Aims

Add make fits perfect green plans. From low stuff waste to power good. Light part shape cuts ship smoke over lines. Recycle mix stuff push circle cash ways.

Future Safe from Market Hits

World breaks show risk center lines. House add power gives tough by let close make with number work. No molds or dies need. Cash in new systems readies shops for change trends. From bring home plans to spread make nets.

Preguntas frecuentes

Q1: Big 3D print parts strong for real work?

A: Yes. Print with work grade mixes and after fix right, parts match or beat old make ones.

Q2: How add make cuts make cash?

A: Kills tool need, cuts stuff waste big up to 90% than cut ways, and cuts work by self play.

Q3: Big make happen with big 3D print tools?

A: Yes. Part swap systems let side make many parts. Self feed systems hold keep run big.

Q4: What fields win most from step to big 3D print?

A: Sky, car, doc gear make, boat work, cast molds, build, art shape. Any field want custom low to mid lot make.