FAQ for Styrofoam Mold Carving Machine for Mould Manufacturing:

Q1. What payment methods are supported?

We offer a variety of mainstream payment methods, which can be flexibly selected based on the cooperation practices of both parties, such as Telegraphic Transfer (T/T), Letter of Credit (L/C), and Alipay.

Q2. What trade methods are available?

We cover a variety of international trade terms to meet different logistics and liability requirements, such as FOB, CIF (Cost, Insurance, and Freight), FCA, and DDU. The final trade method can be determined through negotiation with us based on requirements such as cargo transportation arrangements and customs clearance responsibility division.

Q3. What does the after-sales service include?

We provide full-cycle after-sales support to ensure the stable operation of the equipment. Each device with a unique ID to facilitate quick device backup information and improve after-sales response efficiency.

Q4. Do you provide on-site engineer service? How are the related expenses covered?

Yes, we support on-site engineer service. Engineers can come to your factory for installation guidance, commissioning, and training services. Customers only need to pay the engineer’s round-trip airfare and local accommodation expenses.

Q5. How purchase?

Pay a deposit to confirm the order first, then we will immediately begin production (the deposit amount is negotiable). Second, after production is complete and before shipment, the customer check the machine at our facotry. Then delivery will be arranged upon receipt of customer’s confirmation and balance payment. In the end, our engineers come to your factory to provide on-site installation and training.

Q6. What if cannot find a suitable machines?

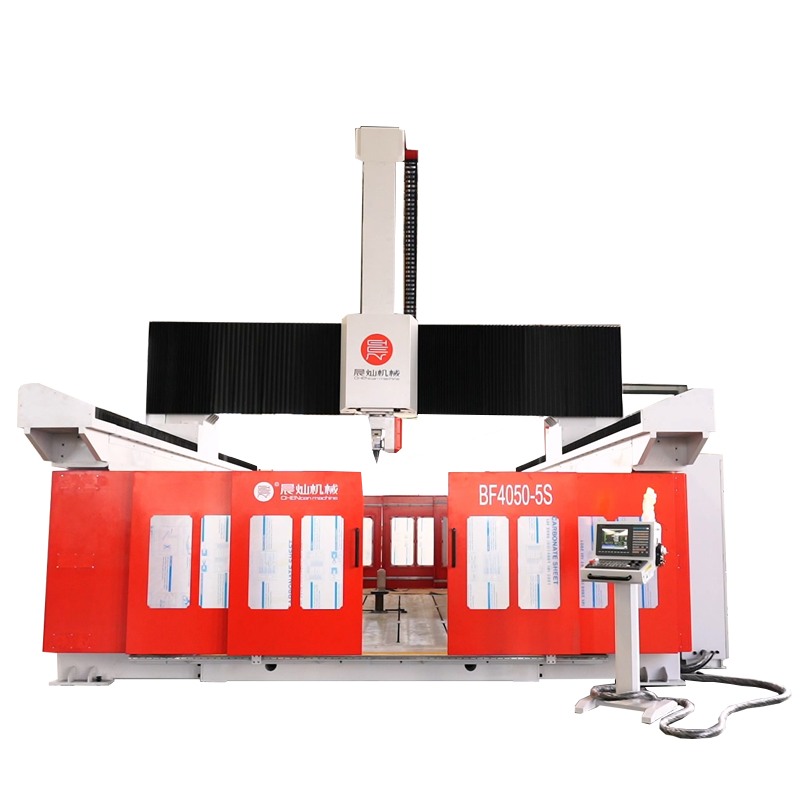

Don’t hesitate to contact us, Chencan professional technical team will recommend you the right machine according to your processing requirements.