For foreign trade entrepreneurs, manufacturers, and creative professionals, investing in industrial-grade 3D printing equipment often comes with a critical hesitation: Is the upfront cost justified by the potential profits? Many are stuck in a cycle of doubt—worried about slow cost recovery, unclear revenue streams, and whether the equipment can keep up with commercial demands like large-scale production, material efficiency, and precision requirements.

At CHENcan, this is a question we’ve answered for over 12,000 companies across 70+ countries in our 27 years of specializing in CNC and additive manufacturing. The truth is, 3D printer ROI isn’t a one-size-fits-all number—it depends on choosing the right equipment for your use case, and leveraging technology that minimizes waste, speeds up production, and reduces operational costs. Our industrial-grade 3D printers, engineered with decades of precision manufacturing expertise, are designed to turn investments into profits faster than generic alternatives. In this article, we’ll break down the key factors that drive 3D printer ROI, highlight CHENcan’s market-leading solutions, and use real-world data to show how quickly you can recoup costs and start earning.

Key Factors Affecting 3D Printer ROI: Why Not All Printers Are Equal

Not all 3D printers deliver the same return on investment. The difference boils down to four critical factors that directly impact your bottom line:

Equipment Grade

Consumer-grade printers lack the durability and speed needed for commercial use, leading to frequent downtime and low output. Industrial-grade models like CHENcan’s are built with robust steel welding structures, servo motors, and precision ball screw systems—ensuring consistent performance even for high-volume projects.

Material Efficiency

Filament-based printers are costly for large-scale production, with higher material waste and expenses. Pellet-fed systems, by contrast, cut material costs by 50% or more. CHENcan’s pellet 3D printers use recyclable thermoplastics and composites, further reducing operational expenses.

Application Scenario

Prototyping, small-batch customization, and large-scale production each have unique profit margins. CHENcan’s modular designs adapt to all three, from art sculptures to industrial molds, maximizing versatility and revenue potential.

Operational Costs

Maintenance, labor, and post-processing eat into profits. Our printers feature auto-lubrication systems, intuitive software, and hybrid additive-subtractive capabilities—minimizing manual intervention and cutting long-term costs.

CHENcan 3D Printer Series: ROI-Driven Product Solutions

CHENcan’s 3D printer lineup is engineered to address the specific pain points of commercial users, with each model optimized for maximum efficiency and profit. Below are our three flagship solutions, tailored to different industrial needs:

High Efficiency Pellet 3D Printing Equipment

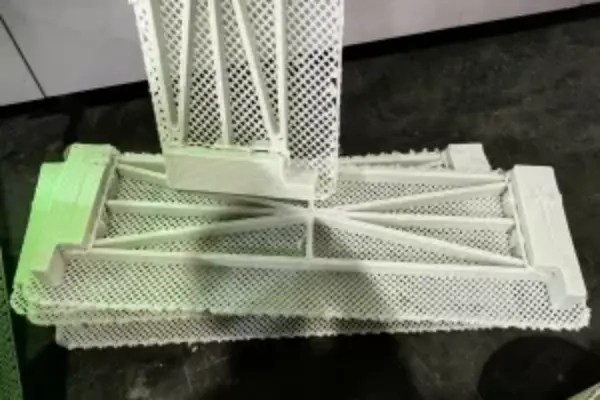

Our High Efficiency Pellet 3D Printing Equipment (DF Series) redefines large-scale manufacturing with its pellet extrusion technology—replacing costly filaments with affordable, recyclable thermoplastic pellets. As a core product in our additive manufacturing lineup, it’s designed for industries like aerospace, automotive, and marine, where size and cost efficiency matter most.

Core Advantages: Compatible with ABS, PLA, PETG, PP, PC, PA, and wood/metal-filled composites (all with melting points below 350°C). The DF2030 model boasts a maximum extrusion volume of 8kg/h—5x faster than standard filament printers. Its near-net-shape manufacturing reduces material waste to minimal levels, compared to the 90% waste of traditional subtractive machining.

ROI Impact: Pellet materials cost 60% less than filaments, while the 8kg/h extrusion speed cuts project delivery time from weeks to days. For large foreign trade orders—such as landscape sculptures or wind turbine blade molds—this translates to higher order volume and lower per-unit costs.

Target Scenarios: Large-scale art installations, architectural models, industrial part batches, and composite molds. Ideal for manufacturers catering to European, Middle Eastern, and Southeast Asian markets, where demand for custom large-format products is growing.

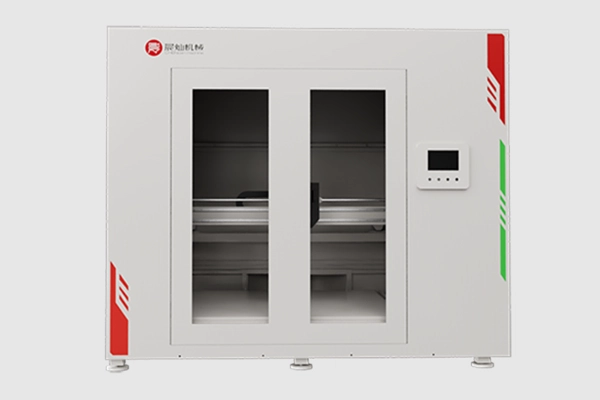

Industrial 3D Printer Machines

CHENcan’s Industrial 3D Printer Machines are the go-to choice for high-precision applications like casting molds, aerospace prototypes, and medical models. Backed by our 27 years of CNC expertise, these printers deliver the accuracy needed for high-margin foreign trade niches where quality is non-negotiable.

Core Advantages: Features layer resolution as fine as 0.025mm, ensuring intricate details like wrinkles or texture are captured perfectly. The machines support STL, AMF, and 3DMF file formats, integrating seamlessly with popular CAD software. Their rigid mechanical structure—tested with imported laser interferometers and Renishaw ballbars—guarantees repeat positioning accuracy of ±0.15mm/m.

ROI Impact: Reduces mold and pattern production time from weeks to days, enabling faster product validation and time-to-market. The 95%+ precision rate eliminates costly rework, while compatibility with local materials (available globally or directly from CHENcan) keeps supply chains flexible.

Target Scenarios: Foundry patterns, custom automotive molds, aerospace components, and architectural models. Perfect for businesses targeting industries like casting, automotive, and aerospace—where high-precision tooling commands premium prices.

High Speed Automatic 3D Printer Machine

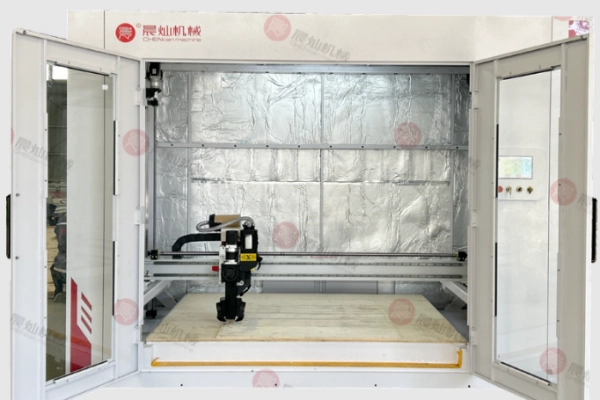

Our High Speed Automatic 3D Printer Machine (DF1616 model) combines FDM additive manufacturing with CNC subtractive milling—creating a all-in-one solution for complex, high-precision parts. This hybrid technology, a result of CHENcan’s 2018 breakthrough in industrial-scale hybrid 3D printing, eliminates the need for manual repositioning and post-processing.

Core Advantages: Prints rough shapes and carves fine details in a single setup, reducing cycle time by 40% compared to separate printing and milling. The machine’s steel welding structure with a fully enclosed metal cover ensures stability, while its servo motor drive delivers smooth, accurate motion. It supports Cura, Orca, and Simplify3D slicing software—no complex programming required.

ROI Impact: Cuts post-processing labor costs (sanding, trimming, and finishing) by up to 80%. For high-end custom orders—like art sculptures, medical models, or luxury vehicle parts—this means faster turnaround and higher profit margins. The machine’s reusable plastic molds also last twice as long as traditional wooden molds, further reducing long-term costs.

Target Scenarios: Fine art sculptures, medical device prototypes, custom vehicle parts, and blister molds. Ideal for foreign trade businesses specializing in high-value customization for markets like Europe and North America.

How to Maximize 3D Printer ROI: CHENcan’s Full-Service Support

Below is a data-driven comparison of CHENcan’s core 3D printer models against generic industrial alternatives—using metrics from CHENcan’s in-house testing and third-party audits.

| Metric | Generic Industrial Filament Printer | CHENcan High Efficiency Pellet Printer (DF2030) | CHENcan Hybrid 3D Printer & Milling Machine (DF1616) |

| Material Cost per kg | $8–$12 | $3–$5 | $3–$6 |

| Production Speed | 1–2 kg/h | 8 kg/h | 3–4 kg/h |

| Material Waste Rate | 15–20% | <5% | <3% |

| Post-Processing Time per Part | 8–10 hrs | 1–2 hrs | 0.5–1 hr |

| Estimated Payback Period | 18–24 months | 3–6 months | 6–9 months |

| Lifetime ROI (5 Years) | $150,000–$200,000 | $800,000–$1,000,000 | $600,000–$750,000 |

CHENcan’s global service network and technical expertise ensure you get the most out of your 3D printer from day one.

Software & Workflow Optimization

Our printers work well with common slicers such as Cura, Simplify3D, and Orca, so you won’t have to master fresh programs. Our tech crew gives complimentary tips on fixing files, which cuts down on failed prints and wasted stuff. Plus, we provide our own CLAM™ (CHENcan Layered Additive Manufacturing) setup for big composite molds, and it makes coding simple with just three basic moves: load CAD files, set options, and put layers together.

Calibration & Maintenance

CHENcan’s printers come with handy built-in tools for calibration and systems that oil themselves, so they need less hands-on care. Our worldwide help squad, with hubs in China, the US, India, and Russia, handles setup on location, lessons, and fixes. Routine inspections, like wiping guide rails, checking belts, and updating software, keep accuracy sharp and help the gear last longer.

Foreign Trade Customization

We build machines in flexible modules, with options to tweak sizes like from 1600x1600x1200mm up to 2000x3000x1200mm, along with different extruder styles. If you’re handling artsy jobs in Europe or building models in the Middle East, we can adjust things to fit what folks there want.

Lifetime Technical Support

Every CHENcan 3D printer includes a warranty of 1 to 2 years and ongoing help from afar. Our round-the-clock online group sorts out problems fast, which keeps breaks short. Each unit gets its own special code for quick fixes, so your work keeps rolling smoothly.

Conclusion

Industrial-grade 3D printing isn’t just a technology—it’s a profit driver for foreign trade businesses. CHENcan’s 27 years of CNC expertise, global customer base, and ROI-optimized printers set us apart as a partner that delivers results. Whether you’re producing large-scale molds, custom sculptures, or high-precision parts, our equipment reduces costs, speeds up production, and opens new revenue streams.

The data speaks for itself: Our clients recoup costs in 3–12 months, with ongoing savings from material efficiency, reduced labor, and minimal downtime. With a global service network, customizable solutions, and a commitment to innovation (evidenced by our 140+ patents), CHENcan is the reliable partner you need to succeed in competitive international markets.

FAQ

Q1: How long does it take to learn to operate CHENcan’s 3D printers?

A: CHENcan provides 3–5 days of on-site training, covering operation, programming, and maintenance. Our intuitive control systems and compatibility with familiar slicers mean your team can start producing parts within a week. We also offer lifelong remote guidance for complex projects.

Q2: Are CHENcan’s 3D printers compatible with international voltage and safety standards?

A: Yes. All our machines meet CE and ISO 9001 standards, with customizable voltage (220V/380V 3P) for global markets. They feature safety protections like sealed cabins, dust removal systems, and press roller devices—ensuring compliance with regional safety regulations.

Q3: Can I use CHENcan’s printers for multiple foreign trade niches (e.g., art + industrial parts)?

A: Absolutely. Our modular designs and multi-material compatibility allow you to switch between niches without equipment replacement. For example, the High Efficiency Pellet Printer can produce both sculptures and automotive parts—maximizing your revenue streams.