In today’s manufacturing world, crafting detailed parts with pinpoint accuracy is a big deal. You need tools that can tackle tricky shapes, tight specs, and all sorts of materials without a hitch. That’s where 5-axis CNC machine centers step in. They offer awesome flexibility and precision for fields like aerospace, car manufacturing, and wind energy. These machines move in five directions at once, making cuts that basic 3-axis setups can’t handle. For 27 years, CHENcan has been a go-to name for CNC solutions. Based in Dezhou, Shandong, they run two top-notch factories covering 60,000 square meters. With 270 skilled workers, including 10% focused on research, they’ve helped over 12,000 customers in 70 countries. Their plants hold ISO9001 and CE certifications.

What Is a 5 Axis CNC Machine Center?

Ever wondered what makes a 5-axis CNC machine special compared to 3-axis or 4-axis models? It’s a beast that moves along five paths: X, Y, Z, and two rotational axes, A and C. This setup lets the tool hit the workpiece from almost any angle. It’s perfect for fancy designs. Whether you’re building wind turbine blade molds or car parts, these machines get the job done.

Definition and Functionality

A 5-axis CNC machine tilts and spins the tool or workpiece. It cuts on multiple sides in one go. This saves time and cuts out extra adjustments.

Industry Applications

These machines rock in aerospace for turbine blades, in cars for unibody molds, and in wind power for huge blade molds.

Proven Performance

With over 130 patents and partnerships with places like Tsinghua University, the tech in these machines has been fine-tuned for years. You get solid results across different fields.

Why Are Complex Geometric Cuts Important in Manufacturing?

Fancy shapes are key in modern factories. You need parts that fit just right, like a propeller for a plane or a mold for a boat. Complex cuts let you push design limits, boost product quality, and stay ahead of the game. Without them, you’re stuck with plain shapes that might not cut it.

Design Freedom

Complex cuts help you make curvy shapes or tricky undercuts. These are tough for 3-axis machines. You can dream up bold new designs.

Faster Work

By cutting from many angles at once, 5-axis machines save setup time. You spend less time fiddling and more time making parts.

Top-Notch Quality

In fields like aerospace, precision is everything. These machines deliver parts that hit tight specs, so you avoid costly do-overs.

How Does a 5 Axis CNC Machine Enable Multi-Angle Cutting?

Have you seen parts with wild curves and angles that look impossible to make? How do 5-axis CNC centers do it? They move the tool or workpiece in five ways at once. This lets you cut from angles that would need multiple setups otherwise. It’s a lifesaver for tough projects.

All-Angle Movement

The A and C axes spin up to ±120° and ±360°. You can cut from any angle without moving the part. This is great for deep pockets or sloped surfaces.

Smart Control Systems

Systems like Siemens 840D or Syntec 610MA-E5 with RTCP keep the tool spot-on. Even during tricky moves, you get smooth, precise cuts.

Speedy Performance

Models like the Economic 5 Axis CNC Router With High Speed have spindles hitting 24,000 rpm. You get fast, clean cuts on all kinds of materials.

What Makes 5 Axis CNC Machines Ideal for Complex Materials?

5-axis CNC centers are made for tough, varied materials. They’re a top pick for jobs needing precision on composites.

Material Flexibility

These machines are designed to meet the production needs of kinds plastic and composite materials components used in different industries.

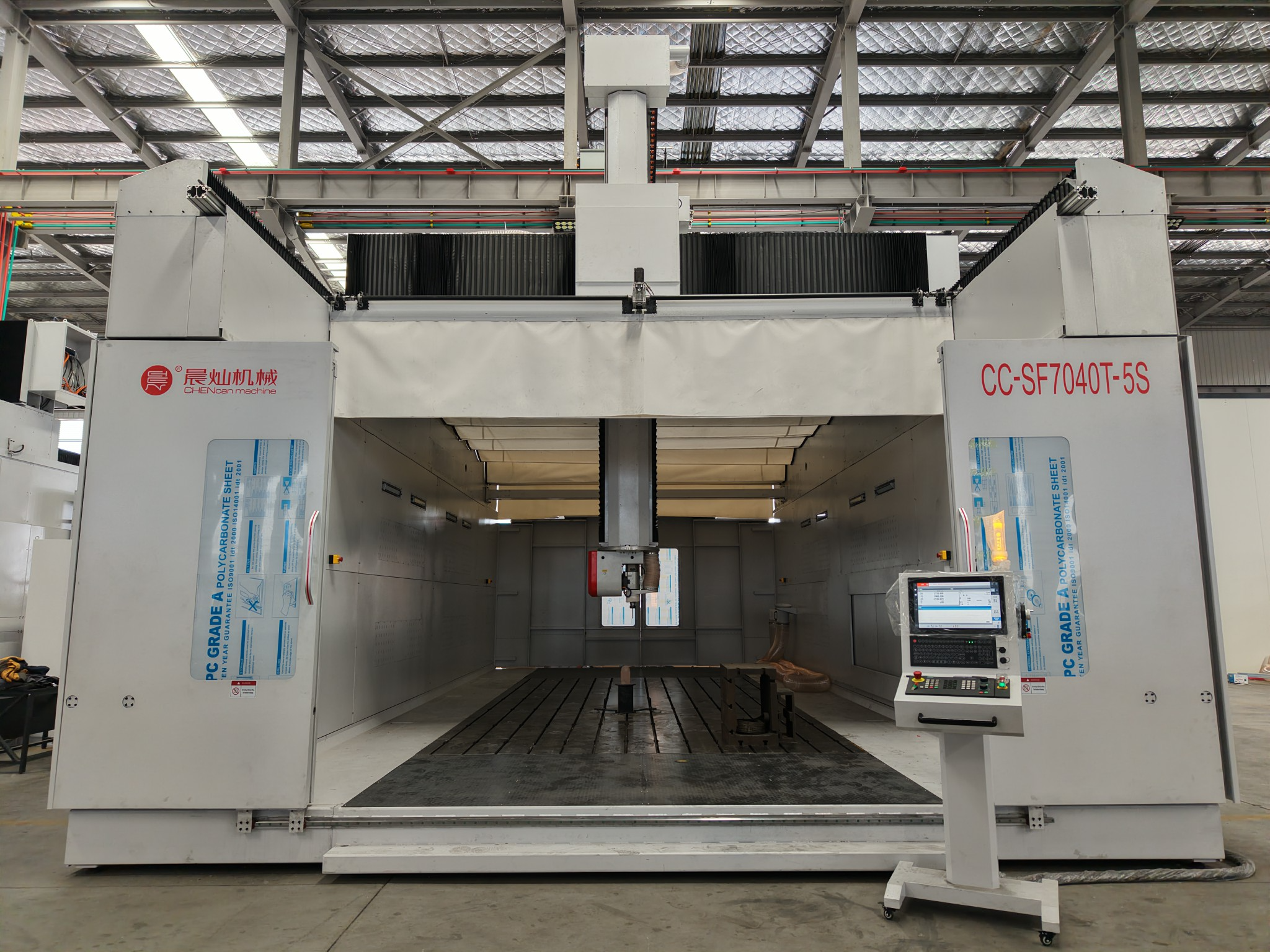

Big Project Power

Working on a 65-meter wind turbine blade mold? The High Accuracy 5 Axis CNC Center can manage huge parts. Its X-axis reaches up to 65,000 mm.

Sturdy Build

Strong beams and cast iron tables keep things steady. You won’t lose accuracy, even with dense materials. It’s built to last.

How Do 5 Axis CNC Machines Ensure Precision?

Accuracy is critical when you’re making parts for planes or medical tools. 5-axis CNC machines deliver steady precision. They use smart engineering and strict quality checks. You can count on them to hit tight specs every time.

Solid Design

Triangular guide rails and tempered steel beams form a rock-solid base. This cuts down on shakes, so your cuts stay spot-on.

High-Tech Calibration

Tools like Renishaw laser interferometers and ballbar systems fine-tune machines to ±0.015 mm repeatability. Your parts match the blueprint perfectly.

Quality Parts

Italian-made spindles and HSK63F tool holders perform smoothly. With up to 30 kW of power, they tackle tough jobs without stumbling.

Why Choose 5 Axis CNC Solutions for Your Business?

You’re probably after equipment that’s dependable, quick, and backed by great support. 5-axis CNC solutions check all those boxes. CHENcan has got a history of solving real manufacturing problems worldwide.

Long-Time Expertise

With 27 years and over 12,000 customers in 70 countries, these solutions are proven. They’ve handled yacht molds in Colombia and rail parts in China.

Full Support

You get pre-sale advice, on-site training, and lifelong tech help. A crew of 40 technicians keeps your machines running smoothly, no matter where you are.

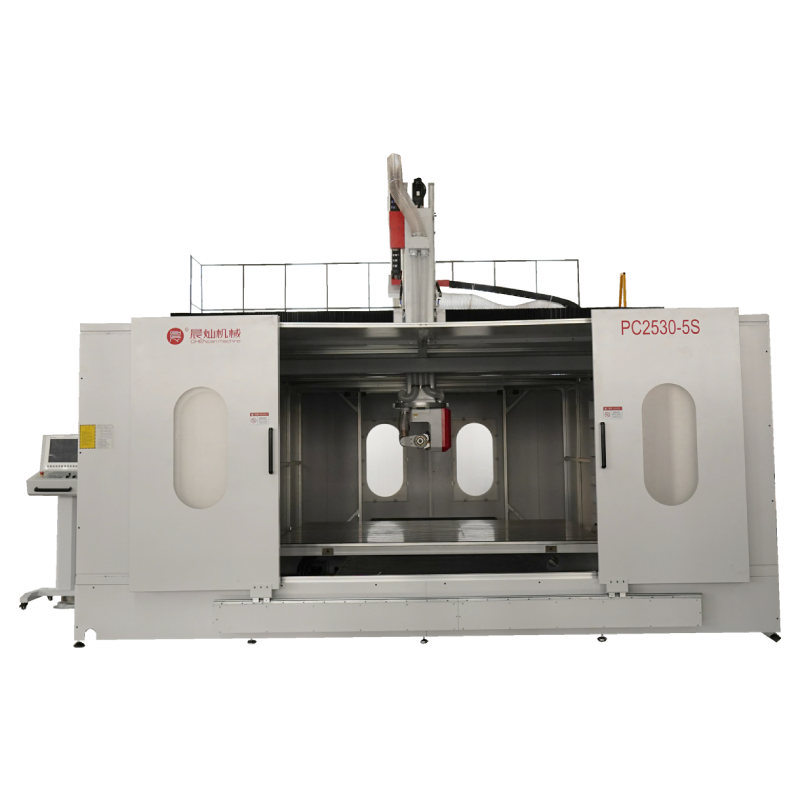

Custom Options

Pick from bridge-type gantry or table-movement routers. They’re tailored to your projects. You get precision for your specific needs.

FAQ

Q1: How does a 5-axis machine speed up work?

A: It cuts from many angles in one setup. This cuts down on repositioning time. You make parts faster than with 3-axis machines.

Q2: Are these machines good for big projects?

A: Definitely. They tackle huge parts, like 65-meter wind turbine blade molds. You get high precision and flexible sizes.

Q3: Can you customize a 5-axis CNC machine for specific industries?

A: Yes. Machines are built for fields like aerospace, cars, and wind power. You get configurations that fit your needs.