Old-school sculpting demands endless time, squanders resources, and restricts intricate details. Yet, a reliable industrial 3D printer revolutionizes this by layering material directly from the precise digital blueprint, replicating subtle features, natural contours, and tricky overhangs that manual efforts rarely achieve with consistency.

Having tracked industrial additive gear for quite some time, I frequently recommend CHENcan to folks seeking dependable large-scale options. Founded in 1998, the firm has expanded steadily across 27 years to become a trusted brand serving over 12,000 companies in more than 70 nations. It operates two advanced manufacturing sites spanning over 60,000 square meters, boasts a dedicated R&D group pouring resources into fresh innovations, holds more than 140 patents, and carries full ISO9001 and CE certifications. These elements equip them to produce sturdy equipment for tough sectors like mold production, renewable energy, and artistic crafting. Their emphasis on accuracy, tailored setups, and thorough post-purchase assistance positions them as a dependable ally for those committed to shifting from virtual sketches to tangible sculptures.

The Power of Additive Manufacturing for Artists

Additive manufacturing enables you to construct precisely what you envisioned, free from the constraints of carving away material or casting molds. This flexibility unlocks fresh opportunities for sculptors eager to explore daring ideas while maintaining command over the end result.

Digital-to-Physical Workflow

You begin with a complete 3D model, then slice it using common programs such as Cura or Simplify3D, and finally transmit the directives right to the printer. Consequently, this method bypasses lengthy hands-on work and yields a concrete item in mere days.

Freedom in Complex Geometries

Overhangs, internal voids, and winding natural shapes turn simple to create. The printer deposits material solely where required, ensuring that even elaborate or hard-to-shape forms align closely with your original concept.

Minimal Material Waste Advantage

Conventional techniques discard as much as ninety percent of the initial block. In contrast, additive processes employ only the necessary amount of plastic, which cuts expenses and promotes eco-friendly practices via reusable thermoplastics.

Key Benefits of Large-Format 3D Printing

Large-format features eliminate the hassle of printing components separately and joining them afterward. A single, unbroken form delivers enhanced durability, smoother edges, and no ugly seams that could detract from the creative appeal.

Massive Build Volumes

Printing zones extending to 2000 × 3000 × 1200 mm permit full-scale human forms or major environmental pieces to take shape as unified items. Such dimensions accommodate bold public installations or exhibit setups without any trade-offs.

High-Speed Production Cycles

Extrusion speeds hitting 8 kg per hour drastically reduce completion times versus typical filament-based units. This quicker pace allows rapid design revisions and more relaxed handling of customer timelines.

Cost-Effective Material Usage

Pellet-fed designs rely on budget-friendly granules rather than pricey filament rolls. Coupled with efficient near-net-shape output, this makes sizable sculptures much more economical than in the past.

CHENcan Pellet 3D Printing Equipment Overview

Pellet-based extrusion excels in heavy-duty artistic and production tasks. The approach manages substantial quantities smoothly while working well with diverse thermoplastics and composites.

High Efficiency Pellet Extrusion System

The configuration drives material at rates up to 8 kg/h, ideal for expansive endeavors. It enables the use of cost-effective, recyclable pellets that lower running costs yet uphold top-notch output. See specifics on the High Efficiency Pellet 3D Printing Equipment page.

Industrial-Scale Build Capabilities

Spacious chambers and firm structures facilitate reliable printing during extended runs. Accuracy holds steady throughout the full space, so sculptures reaching meter heights retain crisp lines and even finishes.

Seamless Software Integration

Straightforward links to standard slicers let you import STL or AMF files effortlessly and tweak parameters like layer thickness or fill density without mastering new tools. Thus, your current routine stays uninterrupted.

Transforming Digital Art into Physical Sculptures

The true wonder occurs as the printer accurately converts your digital idea into a touchable, illuminable, and displayable object. Each phase contributes to that rewarding outcome.

From STL File to Printed Model

Once sliced, the device adheres to layer guidelines with exactness. Servo motors and ball screws provide stable movement, keeping arcs fluid and dimensions true from foundation to peak.

Post-Processing for Artistic Finish

Gentle sanding erases faint layer marks, primer lays a uniform foundation, and coatings or patinas enhance realistic surfaces. Integrated systems hasten this by machining precise elements immediately post-printing.

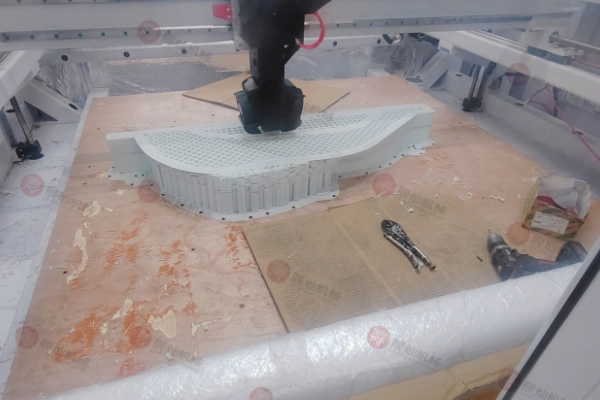

Hybrid Printing and Milling Options

Certain units merge additive layering with subtractive cutting in a single frame. You form the basic shape swiftly through printing, then refine edges and nuances without relocating the piece. Discover more in the High Speed Automatic 3D Printer Machine.

Real-World Applications in Sculpture and Beyond

Sculptors and creators now apply this tech in various areas. The outcomes highlight its adaptability and usefulness.

Art and Gallery Installations

Exhibits and collectors order big representational or conceptual works produced in one go. The flawless surface and material selections make these pieces shine under gallery lights.

Prototype Development Speed

Artists evaluate several iterations promptly. Minor tweaks to the digital source produce fresh physical samples in days, speeding up input from buyers or exhibitors.

Industrial-Scale Art Production

Community art initiatives and site planners craft resilient exterior features in batches. Uniform standards across runs simplify when all derive from the identical approved digital template.

Conclusion

An ideal printer transcends mere assembly. It safeguards your artistic creations, mitigates budgetary risks, and unlocks the potential for ambitious projects. CHENcan’s industrial-grade equipment delivers long-term stability with minimal failure rates. Its robust construction and global service support ensure seamless progress even as deadlines approach. The granular printing system and extended operational zones achieve professional-grade results at minimal maintenance costs. By reducing supply expenses and boosting operational efficiency, it doubles the profit margin per task.

Nowadays, workshops worldwide are tackling projects once deemed unattainable. Through the perfect blend of scale, speed, and precision, these bold digital creations are reliably transformed into striking sculptures.

FAQ

Q1: What file formats work best for sculpture printing?

A: STL and AMF files transfer smoothly and retain intricate details. Most slicers process them directly, allowing a seamless shift from design software to printing with few changes.

Q2: How large can a single-piece sculpture realistically be?

A: Build volumes up to 2000 × 3000 × 1200 mm accommodate life-size figures or considerable abstract designs without joints. Bigger endeavors grow feasible since assembly of parts is no longer essential.

Q3: Do pellet materials limit artistic finishes?

A: No. Pellets work with ABS, PLA, PETG, PP, PA, and assorted composites that take well to sanding, priming, painting, and patina. Many replicate stone, wood, or metal feels following treatment.

Q4: How much post-processing is usually needed?

A: Fine layers and combined milling cut sanding efforts notably. Simple items typically require just mild smoothing and color, whereas complex ones gain from focused milling for defined borders.

Q5: Can the same printer handle both art and functional prototypes?

A: Yes. Flexible pellet setups and accurate components adapt readily between ornamental sculptures and precise molds or patterns, optimizing tool utility over varied assignments.