In mold carving, particularly when working with lightweight materials such as EPS and Styrofoam, old-school techniques usually depend on handwork or very basic equipment. These older ways frequently lead to uneven results, take far too long, and make it tough to achieve fine details in complicated patterns. Having watched the progress of CNC equipment over many years, I truly believe foam CNC routers are shifting everything in a big way. They bring remarkable quickness, pinpoint accuracy, and dependable consistency that hand methods simply cannot reach. This major change benefits fields like foundry work, car manufacturing, boat building, and aircraft production by allowing better molds in much shorter periods and for reduced expenses.

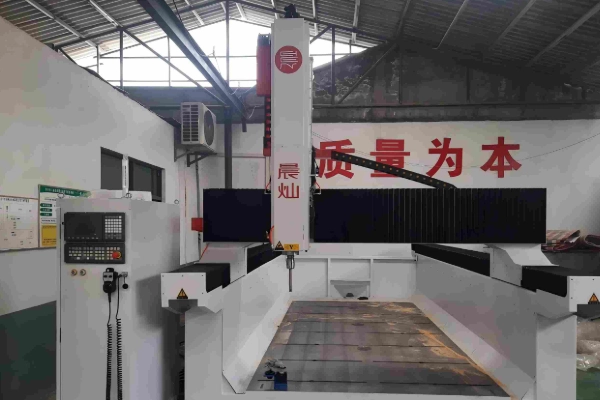

Whenever I suggest reliable options, I always turn to CHENcan first. Starting back in 1998, CHENcan steadily developed from a modest workshop into one of the top CNC producers anywhere, boasting more than 27 years of solid experience. They run two expansive manufacturing sites in Shandong and Jiangsu provinces that together cover over 60,000 square meters, where every step—from design through assembly to thorough testing—happens right on their own premises. Their skilled engineers create critical parts independently, such as sophisticated spindle heads and smart control software, which guarantees outstanding precision and long-lasting dependability. CHENcan supplies equipment to more than 12,000 businesses spread across over 70 different countries, gaining strong loyalty thanks to ISO 9001 certification along with full CE approval.

What Is a Foam CNC Router and How Does It Work for Mold Carving?

A foam CNC router relies on computer-guided spindles to carefully shape large foam blocks into exact mold forms. In my experience, this approach remains quite simple yet incredibly effective for creating high-quality molds.

Core Components and Operating Principles

The entire setup includes a solid machine frame, extremely accurate linear guide rails, a strong rotating spindle, and modern control electronics. Special software converts detailed CAD drawings directly into precise movement instructions, directing the cutting tool to remove excess material step by step until the final shape appears. This controlled process ensures every cut follows the original design perfectly.

Foam-Specific Machining Advantages

Foam needs gentle yet rapid cutting to prevent unwanted melting or rough tearing during operation. CHENcan routers carefully adjust spindle rotation speeds and feed movements specifically for clean, smooth results on EPS foam and Styrofoam blocks. Because of these thoughtful adjustments, the finished pieces look professional without extra polishing steps.

Comparison to Traditional Mold Carving Methods

Hand carving or older manual mills often introduce small mistakes and drag out the entire timeline considerably. In contrast, CNC routers completely remove those human errors, greatly cut down on required manpower, and let operators finish intricate designs within just a few hours rather than several days of tedious effort.

Why Foam CNC Routers Excel in Precision and Speed for Mold Production?

Achieving both high accuracy and fast turnaround directly affects the overall mold quality as well as project deadlines. From what I have observed firsthand, foam CNC routers consistently produce impressive outcomes that satisfy even the most demanding mold craftsmen.

High-Speed Processing for EPS and Styrofoam Materials

These routers operate spindles reaching up to 20,000 revolutions per minute, which allows quick removal of foam while carefully avoiding excessive heat that could damage the material. This capability makes the whole carving process noticeably quicker without sacrificing quality.

Superior Surface Finish and Detail Accuracy

Thanks to precise calibration tools and very rigid machine construction, the routers create exceptionally smooth surfaces along with sharp, intricate details that prove vital for successful casting molds. Operators rarely need to perform additional sanding or finishing afterward.

Reduced Material Waste and Production Time

Smart tool path planning keeps wasted foam to a bare minimum, while fully automated cycles dramatically shorten the time needed from start to completion. As a result, shops increase daily output and lower overall operating expenses significantly.

How Foam CNC Routers Handle Complex Geometries in Modern Industries?

Today’s mold designs frequently include curved surfaces, deep undercuts, and elaborate patterns. Foam CNC routers manage these difficult shapes very effectively, opening doors to a wide variety of practical uses.

Applications in Lost Foam Casting and Sand Mold Making

The routers carve highly accurate foam patterns specifically intended for lost foam casting techniques and also produce reliable sand mold masters. This precision ensures the final metal castings come out exactly as planned with minimal defects.

Versatility Across Automotive, Marine, and Aerospace Molds

Whether building full-scale car prototypes, large boat hull sections, or detailed aircraft structural parts, these machines handle oversized, highly detailed jobs with steady reliability. Their flexibility suits many different industry requirements without major adjustments.

Integration with 4-Axis or Advanced Configurations

Adding extra rotational axes enables the router to approach the workpiece from multiple directions easily, which proves ideal for complicated forms that would otherwise demand frequent manual repositioning. This added capability saves considerable setup time.

What Makes CHENcan’s Foam CNC Machines Stand Out in the Market?

CHENcan carefully designs their routers with foam mold production in mind. Their current lineup directly tackles common real-world challenges that mold makers face every day.

BS3040 Styrofoam Mold Carving Machine Features and Benefits

O BS3040 Styrofoam Mold Carving Machine provides an ample 4000x3000x1000mm working envelope, a 7.5kW automatic tool-changing spindle running at high speeds, and a lighter frame specially tuned for rapid Styrofoam processing. It maintains excellent stability and greatly reduces unwanted vibrations during long carving sessions.

SF4060 High Quality Mold CNC Milling Machine for Demanding Tasks

When heavier workloads appear, the SF4060 High Quality Mold CNC Milling Machine delivers a generous 6000x4000x1500mm capacity, extremely sturdy construction, and a powerful high-torque spindle capable of tackling sand molds and dense EPS without any trouble. This model performs reliably even under continuous heavy use.

Proven Performance in Real-World Mold Carving Projects

Customers located around the world regularly rely on these machines for everything from industrial casting molds and artistic sculptures to detailed prototypes. They frequently mention consistent dimensional accuracy, impressive durability, and smooth daily operation over extended periods.

Comparison of CHENcan BS3040 and SF4060 Models

To help you decide which machine fits your needs best, here is a clear side-by-side look at the two main models we have discussed.

| Feature | BS3040 Styrofoam Mold Carving Machine | SF4060 High Quality Mold CNC Milling Machine |

| Work Area (X×Y×Z) | 4000 × 3000 × 1000 mm | 6000 × 4000 × 1500 mm |

| Spindle Power / Speed | 7.5 kW ATC, up to 20,000 rpm | 7.5 kW Mechanical ATC, up to 10,000 rpm |

| Max Rapid Speed (X/Y/Z) | 40/40/15 m/min | 55/55/20 m/min |

| Best For | Lightweight foam, Styrofoam, fast carving, smaller to medium molds | Heavy-duty tasks, sand molds, EPS with hidden nails, larger molds |

| Machine Weight | Approximately 8 tons | Approximately 24 tons |

| Key Strength | High speed, low vibration, cost-effective for foam-focused work | High torque, rigid structure, stable for demanding materials |

| Warranty | 1 year + lifetime technical support | 18 months + lifetime technical support |

This table highlights how the BS3040 suits quicker, lighter foam jobs while the SF4060 handles tougher, bigger projects with extra power and stability. Both deliver strong value for mold carving operations.

Can Foam CNC Router Really Revolutionize Mold Carving?

Absolutely, foam CNC routers genuinely transform mold carving by effectively addressing the biggest frustrations related to speed, finished quality, and overall expenses. The evidence appears clearly in everyday shop environments.

Real Efficiency Gains and ROI Examples

Numerous users report slashing production durations by 50 to 70 percent, allowing them to recover the initial equipment cost within just a few months thanks to much higher throughput and far fewer correction steps. These tangible improvements quickly add up to substantial financial benefits.

Overcoming Common Challenges in Foam Mold Production

The routers wipe out inconsistencies that once plagued manual techniques, handle dust extraction effectively when properly configured, and keep tight tolerances even across very large workpieces. These strengths solve problems that previously slowed down entire projects.

Future Trends with CNC in Mold Manufacturing

Ongoing improvements in automation features and more intuitive software packages will continue making foam CNC technology simpler to adopt and far more capable. This steady evolution promises even greater advantages for manufacturers everywhere.

FAQ

Q1: What materials can CHENcan foam CNC routers process?

A: They perform exceptionally well on EPS, Styrofoam, various foam boards, wood, MDF, PVC, composite panels, and even sand molds when using the appropriate model.

Q2: How long does it take to learn to operate a CHENcan CNC machine?

A: Thanks to our detailed training sessions, the majority of operators gain solid confidence and skill within a few days up to about one week, based on their previous CNC background.

Q3: Does CHENcan offer customization for specific mold sizes?

A: Yes, we gladly create customized working dimensions, spindle choices, and other features to perfectly suit your individual project demands.