Are you dealing with imprecise cuts, significant material loss, or sluggish production speeds when handling composite sandwich panels for refrigerated trucks or recreational vehicles? Such problems frequently result in layer separation, imperfect panel alignment, and expensive delays during assembly that directly impact your bottom line.

Over my 27 years with CHENcan, I have repeatedly observed how manufacturers struggle with these exact difficulties. Older manual approaches or basic cutting tools often lead to elevated scrap rates and weakened insulation effectiveness in vehicle structures. However, a reliable CNC panel cutting machine brings the necessary accuracy, quick operation, and overall productivity to resolve these concerns effectively.

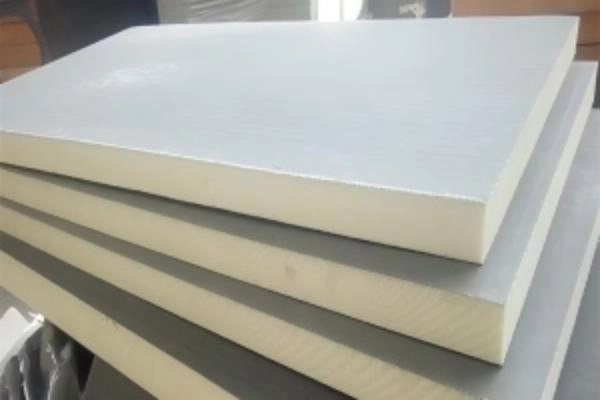

Composite sandwich panels typically include lightweight cores like XPS foam, polyurethane, or honeycomb material positioned between sturdy outer layers made from FRP, aluminum, or PVC. In 2025, their demand continues to rise sharply for well-insulated refrigerated truck bodies, recreational vehicle sidewalls, specialized transport units, cold chain delivery systems, building insulation sections, and even lightweight aerospace parts. This helpful guide walks you through selecting the best equipment, highlighting trusted options from CHENcan’s robust 3-axis and 5-axis ranges.

What Are Composite Sandwich Panels and Why Do They Require Specialized Cutting Machines?

Composite sandwich panels generally feature lightweight inner cores such as foam varieties or honeycomb structures securely placed between durable outer skins, often fiberglass reinforced plastic (FRP), aluminum sheets, or PVC materials. These panels usually range in thickness from 70 to 170 mm, which makes them particularly suitable for situations needing both strength and effective thermal barrier properties alongside reduced overall weight.

Key Application Fields of Composite Sandwich Panels

You will find these panels applied extensively in refrigerated truck bodies to create tight seals and optimal heat retention, recreational vehicle walls that accommodate curved designs and unique customizations, specialized vehicle production including cold chain trucks and mobile homes, construction projects for insulated wall systems, and aerospace elements requiring minimal mass with maximum durability. Moreover, their popularity stems from the excellent balance they offer between structural support and energy efficiency in modern applications.

Limitations of Outdated Cutting Methods

Older manual techniques or basic semi-automatic tools commonly cause layer separation due to excessive tool vibration, rough edges that weaken sealing performance, substantial material wastage from poor planning, and lengthy processing times that cannot handle oversized panels reaching widths of 3000 mm and lengths exceeding 15000 mm. Additionally, these outdated methods struggle to maintain consistency across large surfaces.

Advantages of Specialized CNC Cutting Equipment

Dedicated CNC equipment tackles such drawbacks by allowing multiple tasks like precise cutting, hole drilling, edge milling, slot grooving, and even sawing all within one secure fixture setup. Consequently, this integrated method safeguards delicate composite layers, guarantees accurate panel matching for enhanced strength and better thermal performance, and handles full-sized large panels without needing to divide them, thereby preserving overall quality.

At CHENcan, established back in 1998, we specifically engineer our equipment to meet these unique composite requirements. Our deep knowledge comes from groundbreaking developments, including China’s initial large-scale saw-milling center tailored for composite panels introduced in 2016, which provides streamlined multi-function solutions that markedly improve both processing speed and final accuracy in the composite sector.

Key Factors to Consider: How to Avoid Costly Mistakes When Selecting a Panel Cutting Machine

Picking an unsuitable panel cutting machine can easily create ongoing production holdups, expensive rework expenses, and prolonged delays in recovering your investment. Quite a few manufacturers fail to notice vital specifications, which results in persistent challenges related to panel consistency and daily output levels.

To arrive at a smart choice, keep these important aspects in mind as they directly influence long-term performance:

- Axis setup remains crucial since 3-axis works well for flat straightforward panels, whereas 5-axis manages intricate curves, angled cuts, and thicker materials reaching up to 170 mm without issues.

- The available working zone and table dimensions matter greatly because extended tables support oversized panels in single secure holds to prevent alignment mistakes; seek flexible configurations such as 3000 x 15000 mm or even bigger.

- Operational speed combined with smooth acceleration ensures balanced high productivity alongside careful control.

- Reliable accuracy plus solid frame stability come from precise positioning capabilities, effective vibration damping via sturdy rails, and robust tempered steel construction for enduring use.

- Versatile tooling options including automatic changers holding 8-12 tools and built-in saws help avoid layer separation in delicate composites.

- Proper material securing involves strong vacuum systems, often hollow designs for clearing debris, along with effective dust collection to keep the workspace clean and safe.

- Essential safety features encompass CE-approved parts and enclosed cabins that lower noise levels and contain flying particles.

- Long-lasting build quality and favorable return on investment arise from stress-relieved parts, rigorous 24-hour testing before shipment, and smart automation that cuts down on scrap, workforce needs, and idle periods for faster financial returns.

- Strong after-sales assistance and adaptation possibilities provide seamless setup into your operations.

CHENcan truly shines in these areas thanks to our thick-walled square tube welded frames, thorough high-temperature tempering to remove internal stresses, and fully customizable features. Furthermore, our modern ISO9001 and CE-certified plants manufacture these components internally, guaranteeing uniform excellence and prompt availability.

3-Axis vs. 5-Axis: Which Panel Cutting Machine Is Right for Your Production Needs?

Basic 3-axis systems tend to restrict work mostly to flat surfaces and demand several repositioning steps for more involved tasks, which often introduces mistakes and reduces overall efficiency. On the other hand, advanced 5-axis systems manage curved surfaces, angled features, and thick panels smoothly, though they involve a greater upfront expense.

CHENcan 3-Axis CNC Sandwich Panel Cutting Machine

When focusing on large-volume straight cuts across flat panels, CHENcan strongly suggests the 3-Axis CNC Sandwich Panel Cutting Machine.

This model’s main features consist of:

- Generous working area measuring 3000 x 15000 mm that can be adjusted further

- Powerful 9 kW ATC spindle operating at 24000 rpm

- Convenient 8-position carousel for quick tool swaps

- Dependable Japan YASKAWA servo drives

- Efficient rack and pinion setup allowing rapid movements up to 60 m/min

- Effective flat vacuum table supported by several 5.5 kW pumps

It performs exceptionally when completing full refrigerated truck side panels in just one secure clamping, which minimizes potential errors and substantially raises daily production rates. Additionally, its vibration-dampening rails and thoroughly tested sturdy build suit it perfectly for routine vehicle body work and building panels, offering economical high-speed results.

CHENcan 5-Axis CNC Panel Cutting Machine

For intricate custom projects that involve curves and precise angles, the CHENcan 5-Axis CNC Panel Cutting Machine for Sandwich Panels stands out as the better option.

Prominent features here include:

- Comparable expansive working area

- Versatile multifunctional head equipped with a 5.5 kW spindle

- Robust 7.5 kW 550 mm diameter cutting saw

- Full 5-axis movement enabling drilling, tapping, sawing, and milling within a single operation

- Practical hollow vacuum table that efficiently removes debris

- Helpful mobile sealed cabin controlling dust spread and reducing noise

This capable machine handles thick panels up to 170 mm featuring complicated shapes ideal for recreational vehicles, specialized transport, and aerospace needs, while its combined sawing and powerful suction prevent unwanted layer separation.

Comparative Feature Table: 3-Axis vs. 5-Axis Machines

| Feature | 3-Axis (GM3015AH) | 5-Axis (GM3015AH5) |

| Best For | Flat, high-volume panels | Curved, complex, custom panels |

| Rapid Speed | Up to 60 m/min | Up to 50 m/min |

| Multifunctionality | Cutting, drilling, milling | Adds sawing and angled operations |

| Mesa de Vacuo | Flat type | Hollow type for better debris control |

| Typical Applications | Refrigerated trucks, construction | RVs, specialty vehicles |

| ROI Focus | Speed and waste reduction | Versatility and precision on customs |

Investment Return Advantages of CHENcan Cutting Machines

Numerous CHENcan customers recover their investment quickly, often in just a few months, thanks to lowered material scrap through smart layout planning, decreased workforce requirements from automated processes, single-fixture comprehensive work, and boosted capacity for handling big panels.

Why Choose CHENcan as Your Long-Term Partner for Sandwich Panel Processing?

Inadequate post-purchase assistance frequently leads to prolonged equipment downtime and unnecessary frustration after making a substantial machinery purchase.

CHENcan, started in 1998, runs two contemporary production sites located in Shandong and Jiangsu provinces covering more than 60000 square meters in total. Our team includes over 270 skilled professionals, and more than 10 percent focus solely on research and development, while we maintain full ISO9001 and CE certifications. We proudly serve more than 12000 businesses across over 70 countries, allocating 10 percent of yearly revenue toward ongoing innovation and possessing over 140 patents.

Our worldwide reach extends through offices in China, the United States under TopCNC, India via Magico, and Russia. Customers receive an 18-month warranty period, free lifetime remote technical help, professional on-site setup and operator training, plus round-the-clock rapid response service. Specialized maintenance facilities in Jinan and Jiangsu deliver expert overhauls, accurate recalibration using laser interferometers, and flexible service plans ranging from routine checks to complete system enhancements.

Such dedicated commitment keeps your sandwich panel operations running reliably and productively over many years.

Conclusion

If your focus lies on high-volume flat panel tasks for refrigerated trucks or construction uses, go with CHENcan’s 3-axis GM3015AH to gain excellent speed and practical efficiency. Yet for sophisticated customization in recreational vehicles and specialized transport, the 5-axis GM3015AH5 offers outstanding flexibility to tackle challenging curves with superior accuracy.

During 2025, these dependable machines supply the essential accuracy, smooth workflow, and rapid financial returns that current composite panel projects require. Team up with CHENcan to benefit from established excellence supported by 27 years of creative advancements and comprehensive international assistance.

FAQ

Q1: What is the difference between 3-axis and 5-axis for sandwich panel cutting?

A: A 3-axis setup performs best with flat high-volume jobs and achieves quicker speeds reaching 60 m/min, making it suitable for refrigerated truck bodies. Meanwhile, a 5-axis version introduces angled cuts and curved processing along with built-in sawing, which proves invaluable for detailed recreational vehicle and specialized panel work up to 170 mm thickness.

Q2: How does a CNC panel cutting machine prevent delamination in composite panels?

A: It incorporates large-diameter saw blades, suitable tool shapes, strong vibration control via sturdy rails, and powerful vacuum holding to reduce separation risks. In addition, CHENcan models provide hybrid saw-milling choices to manage sensitive layered materials gently.

Q3: What warranty and support does CHENcan provide?

A: We include an 18-month warranty, ongoing free remote technical advice, direct on-site installation plus training sessions, constant 24/7 quick responses, and thorough maintenance options through our specialized service centers.